Aluminum enclosures are a reliable and durable solution for protecting sensitive electronics and components. But what exactly are they, and why are they so popular in various industries?

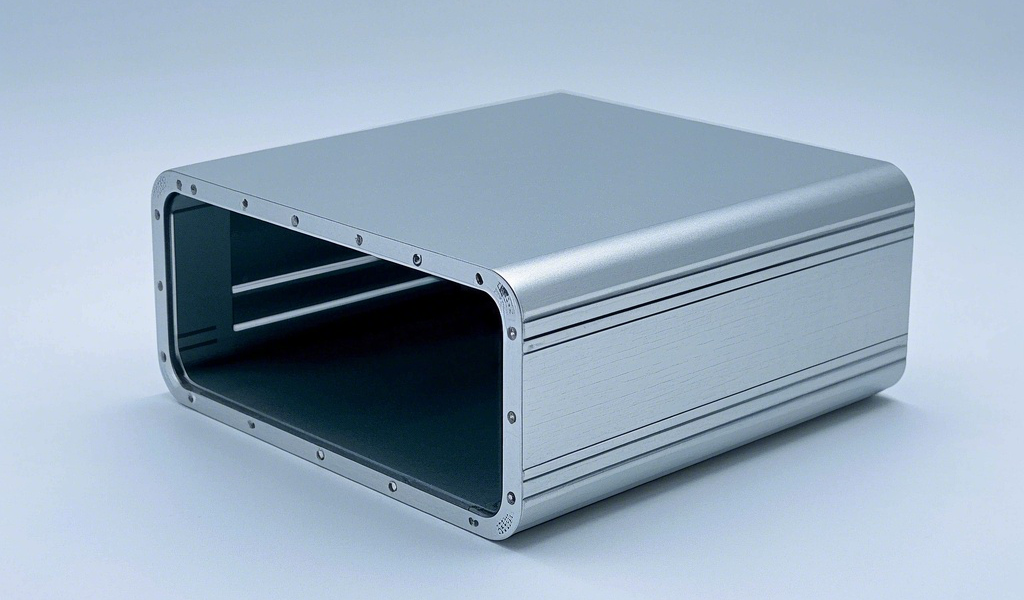

An aluminum enclosure 1 is a protective casing made from aluminum, used to house and shield electronics2 from external elements."

Understanding the role of aluminum enclosures in electronics can help you make informed decisions when sourcing them for your projects.

What is an Aluminium Enclosure?

An aluminum enclosure is a box or casing made from aluminum used to protect electrical or electronic devices. The material is chosen for its light weight, durability, and resistance to corrosion, making it ideal for a variety of applications.

An aluminum enclosure3 is a metal case4 used to protect electronics5from damage caused by environmental factors like dust, moisture, and shock.**

The Benefits of Aluminum Enclosures

Aluminum is a popular choice for enclosures due to its unique properties. It is lightweight yet strong, making it ideal for situations where weight is a concern. Additionally, aluminum is naturally corrosion-resistant due to its protective oxide layer. This makes it a perfect choice for applications in harsh environments, such as outdoor electronics or industrial equipment.

Another significant advantage of aluminum enclosures is their ease of customization. They can be fabricated into various sizes, shapes, and designs, allowing them to fit specific components and meet aesthetic preferences. For example, many manufacturers offer aluminum enclosures with custom-cut holes, mounts for circuit boards, and the option to print logos or branding on the surface.

| Factor | Impact |

|---|---|

| Weight | Lightweight, reducing overall product weight. |

| Durability | Excellent resistance to wear and tear. |

| Corrosion Resistance | Natural oxide layer prevents corrosion. |

| Customizability | Easy to modify to suit specific needs. |

For companies dealing with sensitive equipment, aluminum enclosures provide the perfect balance of strength, durability, and customizability.

What is the Purpose of an Electrical Enclosure?

Electrical enclosures, which can be made from various materials, are essential for protecting electrical components and ensuring their safe operation. Aluminum enclosures serve this purpose particularly well.

The primary purpose of an electrical enclosure is to protect electrical components from external factors, ensuring the safety and longevity of the equipment.

The Role of Electrical Enclosures

Electrical enclosures are crucial in preventing electrical shocks, fires, and equipment damage. They help isolate components from external environments, such as dust, moisture, or chemicals, which could interfere with the proper functioning of electrical systems. In addition to physical protection, enclosures also help in heat dissipation. Electronic devices generate heat during operation, and aluminum enclosures, with their excellent thermal conductivity, help to dissipate this heat effectively, preventing overheating and potential damage to the components inside.

The enclosures also provide grounding, ensuring that any electrical faults are safely directed to the ground, preventing electrical shock hazards. They are often used in both commercial and industrial environments, such as control panels, circuit breakers, and junction boxes, where safety and reliability are paramount.

| Factor | Impact |

|---|---|

| Physical Protection | Shields against moisture, dust, and chemicals. |

| Heat Dissipation | Prevents overheating with aluminum's thermal properties. |

| Grounding | Ensures safety by directing faults safely. |

| Safety Compliance | Helps meet regulatory standards for electrical safety. |

Whether it’s a simple power supply unit or a complex circuit board, electrical enclosures keep the components protected and operational.

What is an Example of an Enclosure?

Enclosures are used in various fields and industries. From industrial equipment to household appliances, they serve to protect and contain sensitive electronics. Aluminum enclosures, in particular, are widely used in many applications.

An example of an enclosure would be a die-cast aluminum box used to house a power amplifier.

Real-World Examples of Enclosures

A power amplifier enclosure made from die-cast aluminum is an excellent example of how aluminum enclosures are used to protect electrical components. These enclosures prevent the amplifier from being damaged by environmental factors like dust or moisture and provide a way for heat to dissipate, keeping the internal components from overheating.

Another common example is the 19-inch rackmount enclosures, widely used in server rooms or telecommunications. These enclosures are designed to hold multiple electronic devices in a standardized, secure format, offering excellent protection while allowing easy access and maintenance.

Aluminum enclosures are also used in instruments like medical devices, control panels for industrial machinery, and even in outdoor electronics like security cameras. Their versatility, strength, and ease of customization make them ideal for nearly any electronic protection need.

| Example | Description |

|---|---|

| Power Amplifier Box | Protects and cools electrical components. |

| Rackmount Enclosures | Standardized protection for multiple devices. |

| Medical Device Cases | Protects sensitive equipment in medical environments. |

| Outdoor Electronics | Provides protection from the elements for devices like security cameras. |

These examples illustrate just how important enclosures are in various sectors, protecting vital electronic components while ensuring their functionality.

What is Aluminum Composite Panel For?

An aluminum composite panel (ACP) is a material made of two aluminum sheets enclosing a non-aluminum core. While it’s often used in construction, its applications extend to other fields, including the design of enclosures for electronics.

Aluminum composite panels are used for both structural and aesthetic purposes in construction and design.

The Versatility of Aluminum Composite Panels

Aluminum composite panels offer a variety of benefits, including lightweight construction, durability, and ease of maintenance. They are used extensively in building facades, signage, and interior applications. When it comes to enclosures, ACPs can be used to provide both structural integrity and a sleek appearance. The panels are often used in environments where aesthetics are just as important as functionality.

In the electronics world, ACPs can be used for larger enclosures or as external panels for housings. Their ability to resist corrosion and withstand harsh environmental conditions makes them a viable option for outdoor electronics. Additionally, ACPs offer superior design flexibility and are available in various finishes, including matte, gloss, and textured, to suit specific design requirements.

| Factor | Impact |

|---|---|

| Lightweight | Easy to handle and install. |

| Durability | Resistant to weathering and corrosion. |

| Aesthetic Appeal | Offers a variety of finishes. |

| Flexibility | Can be used for a wide range of applications. |

Whether for construction or electronics, aluminum composite panels bring a combination of strength, style, and practicality to a range of industries.

Conclusion

Aluminum enclosures offer unmatched protection and customization, making them ideal for housing sensitive electronics. Whether you are looking for a standard enclosure or something with a custom design, aluminum provides both durability and versatility for many industries.

Learn how aluminum enclosures protect electronic components and their advantages over other materials. ↩

Understand what constitutes electronics and the range of devices that use enclosures for protection. ↩

Find out why aluminum is a popular material choice for protecting electronic components ↩

Learn about the role of metal cases in protecting electronic devices from external damage. ↩

Discover which electronic devices benefit from protective enclosures and why. ↩