A product fails in the field, and your customer is frustrated. The return process is confusing and slow, eroding the trust you worked so hard to build.

To fix this, implement a clear post-shipment strategy. Use a 3-tier RMA process1 for efficient handling, an 8D report2 for true root-cause analysis, and maintain a spare parts stock for rapid replacements. This builds unshakable customer trust.

"Building Customer Trust with a Solid RMA Process"

"Building Customer Trust with a Solid RMA Process"

Early in my career, a batch of enclosures we shipped had a subtle cosmetic flaw on the anodizing that only appeared under certain factory lighting. The client was understanding but needed replacements fast. We didn't have a formal process back then. It was chaotic. We pulled units from another customer's order to ship replacements, which created a second problem. We eventually fixed it, but I learned a critical lesson: good intentions don't scale. A reliable, documented process is what truly protects your customers and your business when things go wrong. It turns a potential disaster into an opportunity to show your customer you truly have their back.

How Can a 3-Tier RMA Process Prevent Customer Chaos?

A customer reports a failure. Your team is scrambling, unsure if it's a simple user error or a critical defect. Engineers get pulled into basic support calls, wasting valuable time.

A tiered system solves this. It triages issues so simple problems are solved instantly and only complex hardware failures are escalated, creating a clear and efficient RMA process.

"The 3-Tier RMA Process Flowchart"

"The 3-Tier RMA Process Flowchart"

A structured, three-level approach brings order to the chaos of field failures. It ensures you use the right resources for the right problem, saving time for both you and your customer. The goal is to solve the issue at the lowest possible tier. Tier 1 is your front line, often customer service, equipped with a knowledge base to solve common issues like setup questions or known software bugs. Tier 2 is for escalation to technical support or product specialists who can diagnose more complex interaction or configuration problems. Only when a true hardware failure is confirmed by Tier 2 do you move to Tier 3, which is the formal Return Material Authorization (RMA). At this stage, the unit is returned for failure analysis by the engineering team. This structure keeps engineers focused on engineering, not basic support, and provides a smooth, professional experience for the customer.

The Three Tiers of Support

| Tier | Responsibility | Goal | Customer Experience |

|---|---|---|---|

| Tier 1 | Customer Service / Front Line | Solve >50% of issues with scripts. | Instant help for common problems. |

| Tier 2 | Technical Support / Product Specialist | Diagnose complex issues remotely. | Expert guidance for tough issues. |

| Tier 3 | Engineering / Quality Assurance | Authorize return, perform analysis. | Decisive action on confirmed failures. |

Why is an 8D Report More Than Just Paperwork?

You replaced a failed product. But a month later, another one fails for the exact same reason. You are trapped in a costly cycle of replacing products without ever fixing the core issue.

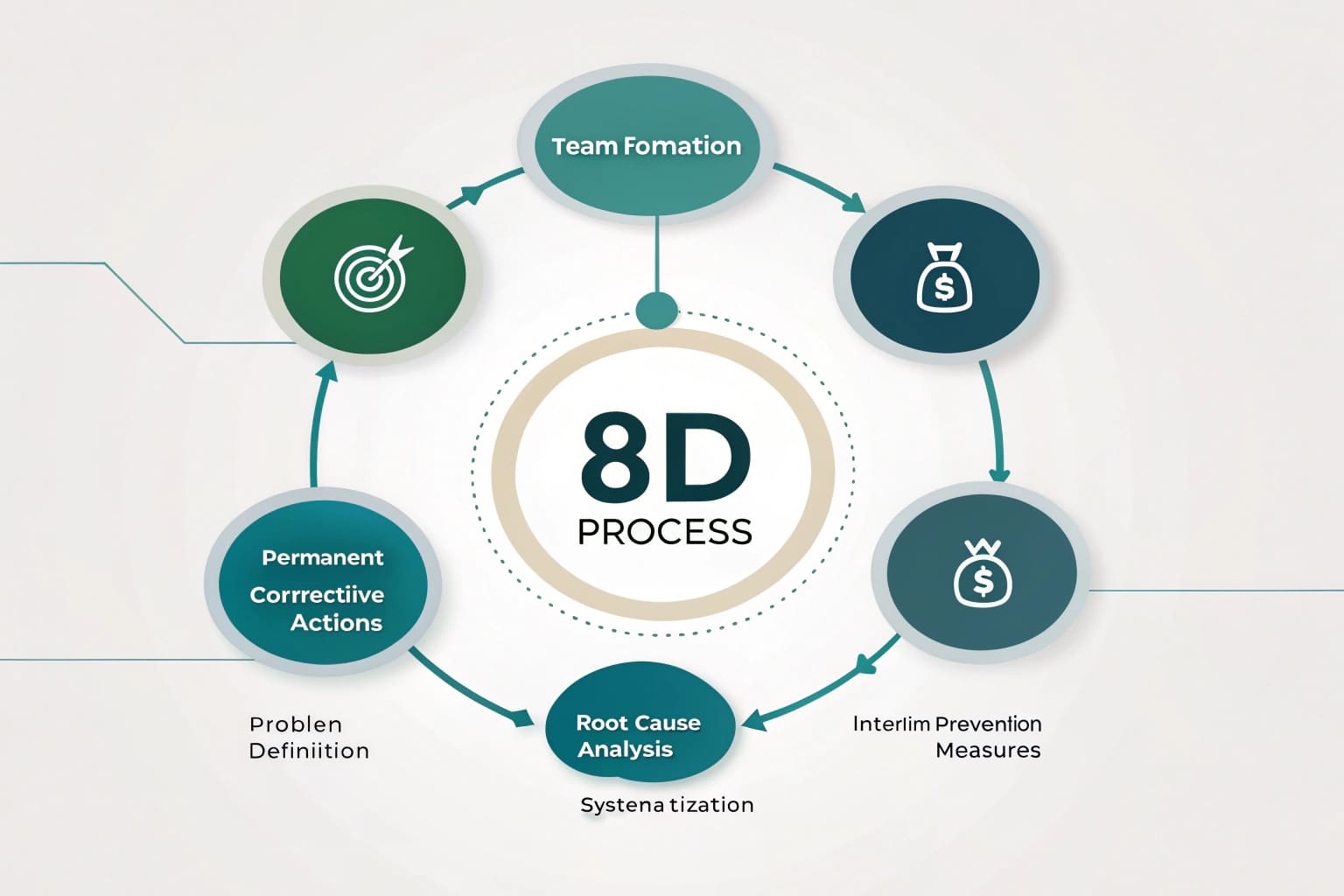

An 8D report is your way out. It’s a structured methodology that forces you to dig for the true root cause and implement changes to ensure the problem never happens again.

"The 8D Report Problem-Solving Cycle")

"The 8D Report Problem-Solving Cycle")

The 8D report, which stands for the Eight Disciplines of Problem Solving, is one of the most powerful tools in manufacturing. It transforms you from a firefighter into a fire marshal. Instead of just "fixing" the symptom (a broken product), it forces a deep investigation to eliminate the disease. For instance, if a seal on an enclosure fails, the 8D process pushes you past the obvious. The immediate cause might be a torn gasket. But why did it tear? Using a "5 Whys" analysis, you might find the gasket groove was machined too shallow. Why? The CNC program used the wrong tool offset. Why? The setup sheet was unclear. The permanent corrective action isn't just to use a new gasket; it's to revise the setup sheet, retrain the operator, and add a quality check for groove depth. This rigorous approach is how you achieve real, lasting quality improvements.

The Eight Disciplines (8D) at a Glance

| Discipline | Purpose | In Simple Terms |

|---|---|---|

| D1: Form a Team | Get the right people involved. | Assemble the experts. |

| D2: Define the Problem | Quantify the issue with data. | What, where, when, how many? |

| D3: Contain the Problem | Stop the bleeding. | Quarantine bad parts. |

| D4: Find Root Cause | The most critical step. | Ask "Why?" until you can't anymore. |

| D5: Verify Corrective Actions | Prove your fix will work. | Test the proposed solution. |

| D6: Implement Permanent Fix | Make the change in the process. | Update drawings, tools, and training. |

| D7: Prevent Recurrence | Make it impossible to happen again. | Update your quality system. |

| D8: Congratulate Team | Recognize the effort. | Acknowledge the hard work. |

Does a Spare Parts Stock Really Save Money?

Your customer's production line is down because one of your products failed. You can make a replacement, but the lead time is three weeks. The customer's cost of downtime is astronomical.

Yes, a spare parts program saves money. While it costs a little to hold inventory, a dedicated spare parts stock3 can be shipped immediately, preventing catastrophic customer downtime and preserving the relationship.

"Dedicated Spare Parts Stock for Fast RMAs"

"Dedicated Spare Parts Stock for Fast RMAs"

Thinking a spare parts stock is just a cost center is a classic mistake. It's an insurance policy on your customer relationships. The cost of holding a few extra enclosures, end plates, or gasket sets in inventory is trivial compared to the cost of a customer's production line being idle for weeks. The key is to be strategic. You don't need to stock every single custom component. Start by stocking standard, long-lead-time items and any parts that, while inexpensive, are critical to the product's function. We advise clients to maintain a small, physically separate inventory dedicated solely to RMAs and service requests. This ensures that a customer emergency doesn't disrupt your planned production schedule. The ability to tell a customer "A replacement is on its way and will ship today" is one of the most powerful ways to build loyalty and customer trust.

The True Cost of a Field Failure

| Metric | Without Spare Parts Stock | With Spare Parts Stock | The Financial Impact |

|---|---|---|---|

| Customer Downtime | Weeks | Hours | Saves your customer thousands. |

| Replacement Time | 2-4 Weeks (Production Lead Time) | < 24 Hours (Shipping Time) | Builds incredible customer loyalty4. |

| Brand Reputation | Damaged (seen as slow, unreliable) | Enhanced (seen as fast, responsive) | Protects future sales. |

| Your Internal Cost | High (expedite fees, disruption) | Low (predictable inventory cost) | More efficient and less stressful. |

Conclusion

Post-shipment support is not an expense; it's an investment. A disciplined RMA process, deep 8D report analysis, and a ready spare parts stock are the pillars of building lasting customer trust.

Understanding the 3-tier RMA process can help streamline your return handling and improve customer satisfaction. ↩

Exploring the 8D report methodology can enhance your problem-solving skills and prevent recurring issues. ↩

Learn how a spare parts stock can save money and improve customer relationships by reducing downtime. ↩

Explore ways to foster customer loyalty, which is vital for long-term business success. ↩