Facing overheating issues with aluminum amplifier enclosures? Poor thermal management reduces audio quality, shortens equipment lifespan1, and increases the risk of sudden failures.

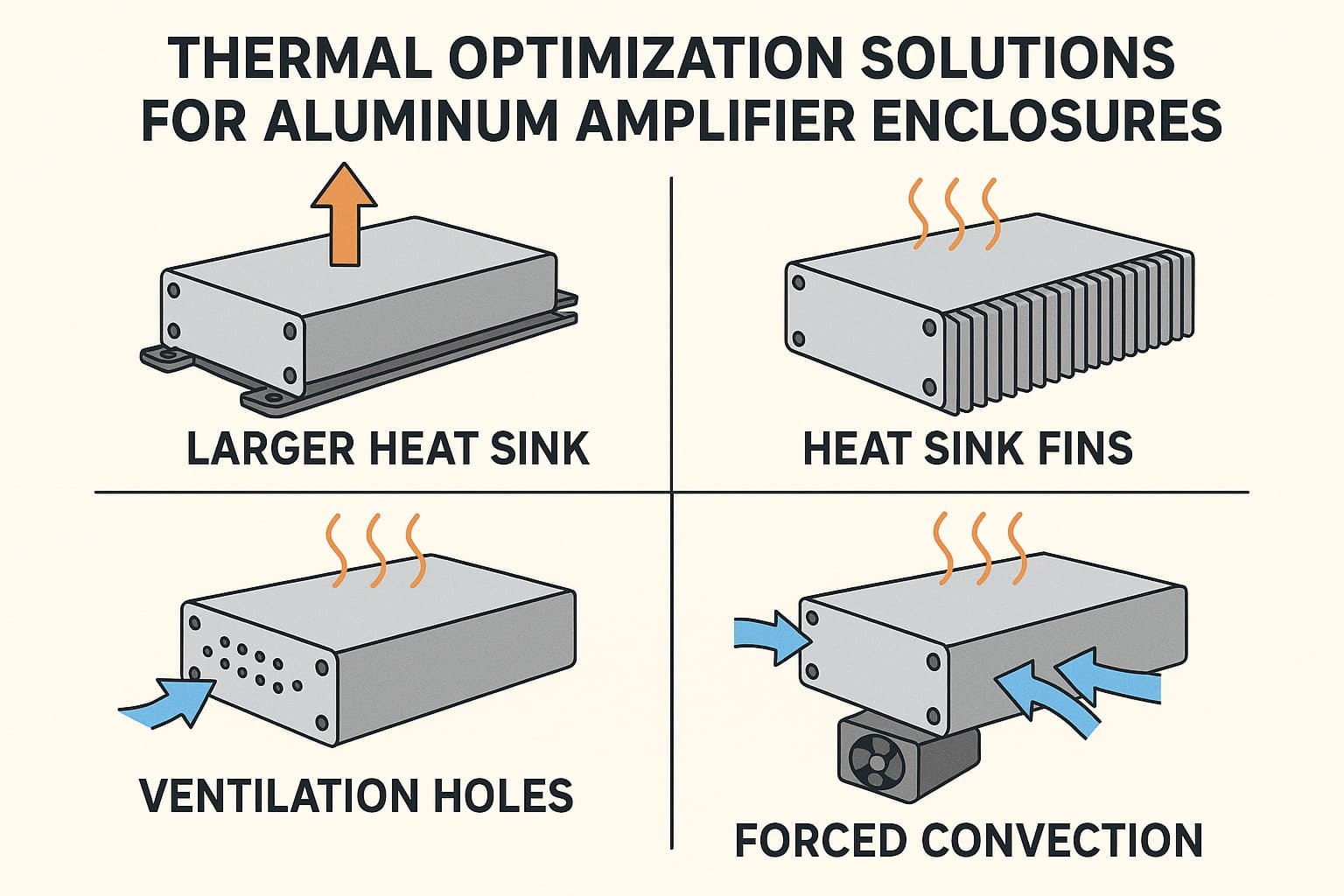

Effective thermal optimization2 for aluminum amplifier enclosures involves using enhanced heat sink designs3, optimizing airflow4 with ventilation and fans, utilizing thermal interface materials5, and employing surface treatments6 like anodizing to boost heat dissipation7.

I've seen many amplifier designs struggle with thermal issues, leading to costly performance degradation8. Let's explore proven thermal optimization2 techniques that ensure reliable and efficient amplifier operation.

How does heat sink design impact amplifier enclosure cooling?

Is your amplifier overheating despite standard heat sinks? Inadequate heat sink design can lead to excessive heat buildup, causing distortion or equipment failure.

Optimized heat sink designs3 featuring large surface areas, strategically placed fins, and efficient heat conduction paths significantly improve heat dissipation7, reducing internal temperatures and ensuring consistent amplifier performance.

"Heat Sink Design for Aluminum Amplifier Enclosures"

"Heat Sink Design for Aluminum Amplifier Enclosures"

In my experience, heat sink design is fundamental for cooling amplifiers. Aluminum enclosures are naturally thermally conductive, but standard flat surfaces aren't enough for amplifiers generating substantial heat. Effective heat sink designs3 use enhanced features like:

- Increased Surface Area: Larger fins or extrusions boost convection cooling.

- Fin Orientation: Vertical fins improve natural airflow4.

- Enhanced Conductivity: Thicker base plates facilitate faster heat spreading.

Comparison of heat sink designs3:

| Heat Sink Type | Thermal Efficiency | Complexity | Cost Impact |

|---|---|---|---|

| Flat Plate | Low | Simple | Low |

| Ribbed Extrusions | Medium | Moderate | Moderate |

| Fin-type Extrusions | High | High | Moderate-High |

From my projects, fin-type extrusions consistently delivered superior cooling, significantly enhancing amplifier reliability.

Why is optimized ventilation9 critical in amplifier enclosures?

Experiencing inadequate cooling despite quality heat sinks? Poor ventilation restricts airflow4, trapping heat inside and leading to performance degradation8.

Optimized ventilation—strategically placed vent holes, slots, and integrated fans—facilitates efficient airflow4, significantly reducing internal enclosure temperatures and improving amplifier cooling performance.

"Optimized Ventilation for Aluminum Amplifier Enclosures")

"Optimized Ventilation for Aluminum Amplifier Enclosures")

I’ve worked on multiple amplifiers where inadequate ventilation severely affected performance. Simply adding more ventilation holes isn't sufficient. Proper ventilation requires carefully positioned vents or integrated fans for effective airflow4. Key considerations include:

- Vent Location: Bottom intake and top exhaust create optimal airflow4.

- Fan Integration: Active cooling with fans dramatically boosts heat removal.

- Dust Protection: Mesh filters maintain cleanliness while allowing airflow4.

Comparison of ventilation methods:

| Ventilation Method | Cooling Effectiveness | Complexity | Noise Level |

|---|---|---|---|

| Passive (holes/slots) | Moderate | Low | Silent |

| Active (fans) | High | Moderate | Low-Moderate |

Active ventilation with fans has consistently proven most effective, providing substantial cooling performance gains, especially for high-power amplifiers.

How do thermal interface materials5 enhance amplifier enclosure cooling?

Noticing persistent overheating despite good heat sinks and ventilation? Poor heat transfer between amplifier components and the enclosure might be limiting performance.

Thermal interface materials (TIMs), such as thermal pads, thermal grease, or gap fillers, significantly improve heat transfer efficiency between amplifier components and aluminum enclosures, preventing overheating and ensuring consistent audio performance.

"Thermal Interface Materials for Amplifier Enclosures"

"Thermal Interface Materials for Amplifier Enclosures"

I've observed many amplifiers improved by simply adding or upgrading thermal interface materials5. TIMs reduce the air gap between hot components and aluminum surfaces, dramatically increasing heat transfer effectiveness.

Common TIM options include:

| Material | Thermal Conductivity | Ease of Use | Cost Impact |

|---|---|---|---|

| Thermal Grease | High | Moderate | Low |

| Thermal Pads | Medium-High | Easy | Moderate |

| Gap Fillers | Medium | Easy | Moderate |

Using thermal pads typically provides an ideal balance between thermal performance and ease of assembly. Properly applied TIMs significantly reduce overheating risks, enhancing overall amplifier reliability.

Can anodizing aluminum10 improve thermal performance of amplifier enclosures?

Are you underestimating the role of surface treatment in amplifier cooling? Ignoring anodizing could mean missed opportunities for improved thermal performance.

Anodizing aluminum surfaces increases emissivity, enhancing heat radiation and improving overall passive cooling11 performance in amplifier enclosures, thus effectively reducing operating temperatures.

"Anodizing Impact on Thermal Performance"

"Anodizing Impact on Thermal Performance"

Anodizing isn’t just cosmetic; it directly impacts thermal management. In my experience, anodized surfaces noticeably improve passive cooling11 by increasing emissivity, allowing more heat to radiate away from the enclosure. This effect becomes especially important in passive cooling11 scenarios or enclosed spaces.

Comparison of aluminum finishes:

| Surface Finish | Emissivity Level | Cooling Performance | Cost Impact |

|---|---|---|---|

| Bare Aluminum | Low | Moderate | Low |

| Anodized Aluminum | High | High | Moderate |

| Painted Aluminum | Medium | Medium | Moderate |

Choosing anodizing significantly boosts cooling performance, providing reliable thermal optimization2 in aluminum amplifier enclosures.

Conclusion

Effective thermal optimization2 for aluminum amplifier enclosures relies on well-designed heat sinks, optimized ventilation9, proper thermal interface materials5, and anodized surfaces, ensuring stable performance and long-lasting reliability.

Understand the relationship between thermal management and the longevity of electronic equipment. ↩

Explore this resource to learn effective strategies for enhancing thermal management in amplifier enclosures. ↩ ↩ ↩ ↩

Discover how innovative heat sink designs can significantly improve cooling efficiency and amplifier performance. ↩ ↩ ↩ ↩

Explore effective techniques to enhance airflow and cooling in amplifier designs. ↩ ↩ ↩ ↩ ↩ ↩ ↩

Find out how thermal interface materials can enhance heat transfer and prevent overheating in amplifiers. ↩ ↩ ↩ ↩

Learn about various surface treatments that can improve heat dissipation and overall amplifier performance. ↩

Find out the best strategies for heat dissipation that can be applied to various electronic devices. ↩ ↩

Explore the factors that lead to performance degradation in amplifiers and how to mitigate them. ↩ ↩

Learn about the critical role of ventilation in maintaining optimal temperatures for amplifier performance. ↩ ↩

Understand the advantages of anodizing aluminum for better thermal management in amplifier enclosures. ↩

Explore passive cooling methods that can enhance thermal performance without active components. ↩ ↩ ↩