How Are IP68 Waterproof Aluminum Enclosures Made?

Your electronics are at risk from water damage. A standard box won't protect them in harsh conditions, leading to costly failures. A properly designed enclosure is your best defense.

Creating an IP68 waterproof aluminum enclosure involves precision design, the right materials like silicone gaskets, and rigorous testing under specific conditions of pressure and time to ensure a complete and reliable seal against continuous water immersion.

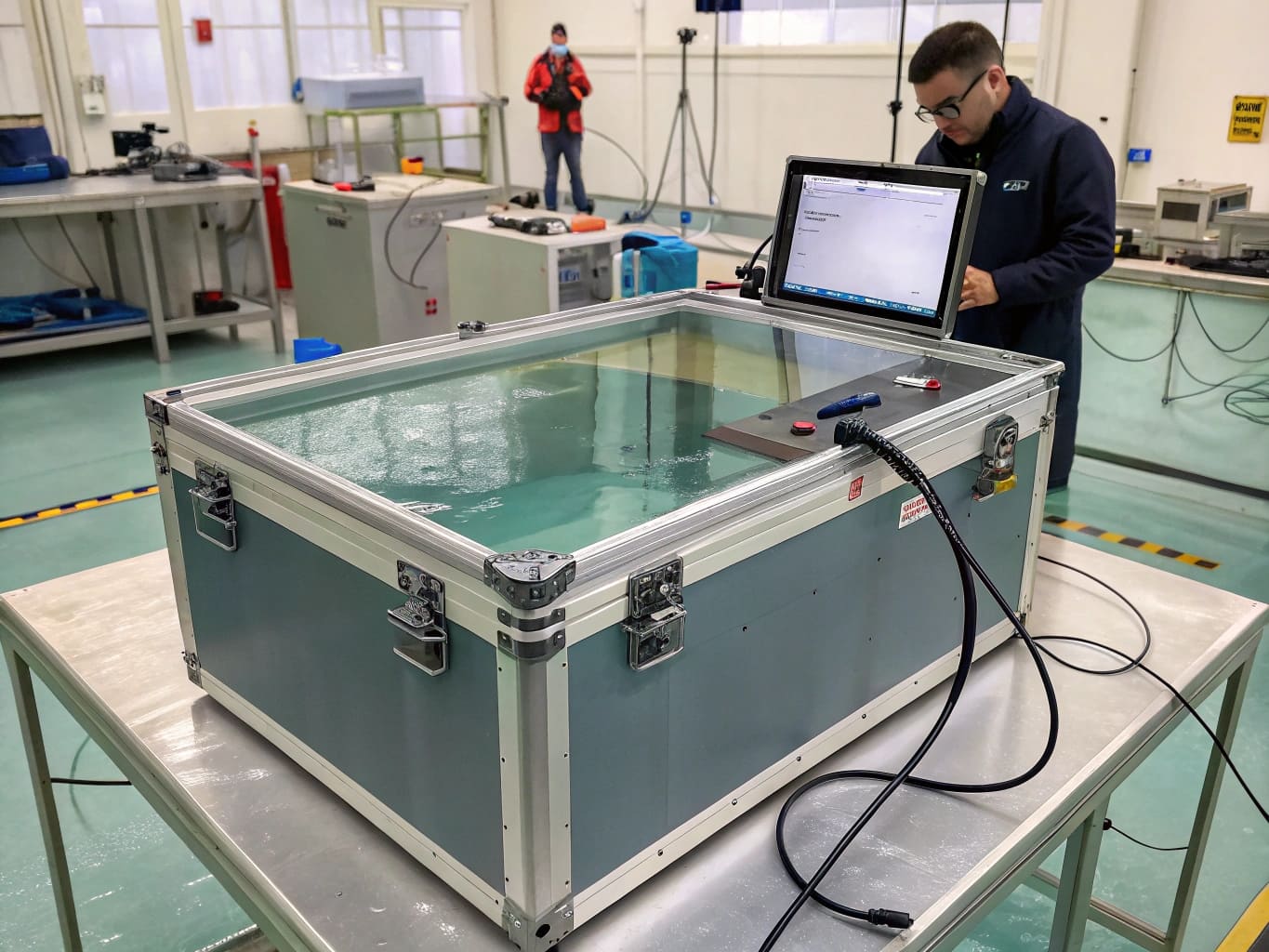

“IP68 waterproof aluminum enclosure undergoing water immersion test”)

“IP68 waterproof aluminum enclosure undergoing water immersion test”)

Achieving this high level of protection isn't a simple task; it's a meticulous engineering process. It's about more than just a good seal; it’s about ensuring that seal holds up under real-world pressure. Let's walk through exactly how these robust enclosures are designed and validated.

What is an IP68 enclosure?

You see "IP68" on products everywhere, but what does it actually mean for an enclosure? Misunderstanding this rating can lead you to choose a product that fails when you need it most.

An IP68 enclosure is a housing certified to be completely dust-tight (the '6') and protected against continuous immersion in water under conditions specified by the manufacturer, which are more severe than the 1-meter depth required for IP67 (the '8').

“Infographic showing IP68 protection against dust and water”)

“Infographic showing IP68 protection against dust and water”)

Breaking Down the IP Code

The IP (Ingress Protection) rating is a global standard. It gives you a clear and simple way to understand the level of protection an enclosure offers. I've seen many engineers, like my typical client Jeff, struggle with vague terms like "water-resistant." The IP code removes that ambiguity. It’s made up of two digits:

- First Digit (Solids): This number ranges from 0 to 6 and indicates the level of protection against solid objects, from large body parts down to microscopic dust. A '6' means the enclosure is completely dust-tight.

- Second Digit (Liquids): This number ranges from 0 to 9 and describes protection against moisture, from simple drips to high-pressure jets and full immersion. An '8' signifies protection against continuous, deep submersion.

Here’s a quick breakdown:

| Digit | First Digit (Solid Protection) | Second Digit (Liquid Protection) |

|---|---|---|

| IP6_ | 6: Dust Tight | - |

| IP_8 | - | 8: Continuous Immersion (beyond 1m) |

For an aluminum enclosure to achieve this, the design must be flawless. It needs a continuous gasket channel, precisely machined surfaces for the gasket to seal against, and enough fasteners to apply even pressure. This is why we at PUMAYCASE focus on integrated manufacturing—controlling the CNC machining and finishing under one roof ensures the precision needed for a reliable IP68 seal.

What is the IP68 testing process?

You have a product that needs to be waterproof. But how do you prove it actually meets the IP68 standard? Without a formal test, you're just guessing, and that's a risky bet.

The IP68 testing process involves completely submerging the enclosure in water at a specific depth and for a specific duration, as agreed upon by the manufacturer and user. After the test, the enclosure is opened and inspected for any water ingress.

“Post-test inspection for IP68 certification”)

“Post-test inspection for IP68 certification”)

Steps of a Validation Test

The key to IP68 is that the conditions are defined. Unlike IP67 (which is standardized at 1 meter for 30 minutes), IP68 is "harsher than IP67," and the manufacturer must state the exact test parameters. I remember working with an engineer who was developing a sensor for monitoring agricultural irrigation systems. He needed his device to survive submerged in a water tank for weeks at a time at a depth of 2 meters. We had to design and test for that specific scenario.

The process we followed is a good example of how it works:

- Define the Conditions: We first agreed on the test parameters: a depth of 2 meters of water for a duration of 14 days. This became our pass/fail criteria.

- Prepare the Enclosure: The enclosure was fully assembled just as it would be in the field. This included all gaskets, fasteners torqued to spec, and sealed cable glands with cables passing through them.

- Submersion: We placed the enclosure in a custom-built pressure vessel. The vessel was filled with water and pressurized to simulate a 2-meter depth. This pressure was maintained continuously for the full 14-day period.

- Post-Test Inspection: After 14 days, the enclosure was removed, carefully dried on the outside, and then opened. We meticulously inspected the interior for any sign of moisture—even a single drop would mean failure. We also placed water-sensitive paper inside as a secondary check.

Fortunately, it passed with flying colors. By offering validated reports for tests like these, we help our clients save thousands on third-party testing and launch their products with confidence.

Is IP68 completely waterproof?

The term "waterproof" sounds absolute, leading many to believe an IP68 device is invincible against water. This misunderstanding can be costly when a device fails under conditions you thought it could handle.

No, IP68 is not "completely waterproof" in an absolute sense. It means the enclosure is waterproof only under the specific conditions of depth and time for which it was tested. Exceeding these limits can still lead to water ingress and failure.

“Diagram illustrating the limits of waterproof ratings”)

“Diagram illustrating the limits of waterproof ratings”)

Understanding the Limits

Think of "waterproof" as a performance rating, not a permanent state. A deep-sea submarine is waterproof, but only up to its maximum rated depth. The same principle applies to an IP68 enclosure. The '8' in the rating is conditional. A phone rated for 1.5 meters for 30 minutes is not guaranteed to survive at 3 meters for an hour. The increased water pressure can force water past seals that were not designed for that stress.

Here are the key factors that define the limits:

- Pressure (Depth): The deeper you go, the higher the external pressure on the enclosure and its seals. A gasket that works at 2 meters might fail at 20 meters.

- Time (Duration): Materials can degrade or "creep" over time. A seal might hold for 30 minutes but could begin to fail after 30 days of continuous pressure, especially if temperature fluctuations cause materials to expand and contract.

- Water Type & Temperature: The tests are typically done in fresh water. Saltwater is more corrosive, and chemicals or temperature extremes can affect the integrity of gasket materials.

I once consulted on a project where a client's IP68-rated enclosure for a marine buoy kept failing. The issue was that the enclosure was only rated for 3 meters, but strong waves were temporarily pushing the buoy much deeper, causing pressure spikes that breached the seal. We had to re-engineer the enclosure with a thicker flange and a more robust gasket to handle those dynamic loads.

What are the terms and conditions for IP68?

You know IP68 conditions are manufacturer-defined, but what does that mean in practice? Not knowing these details can lead you to buy an enclosure that doesn't actually meet your project's specific needs.

The "terms and conditions" for IP68 are the specific depth and duration of water immersion that the enclosure is certified to withstand. The manufacturer must clearly state these parameters, for example, "IP68 – 3 meters for 24 hours."

“Technical document showing IP68 depth and time rating”

“Technical document showing IP68 depth and time rating”

Why Specificity Matters

This is where the partnership between the user and the manufacturer becomes critical. As a product engineer, you need to know the environment your device will live in. As a manufacturer, I need that information to design the right solution. Simply asking for "an IP68 box" isn't enough. The difference between an enclosure designed for 1.5 meters and one for 10 meters is significant.

The design choices are directly impacted by the specified conditions:

| IP68 Condition | Design Implication | Example |

|---|---|---|

| Shallow (1-3m) | Standard wall thickness, standard silicone gaskets, and normal fastener torque are often sufficient. | A sensor for a home swimming pool. |

| Moderate (3-10m) | May require a thicker enclosure wall, a higher durometer (harder) gasket, and more fasteners. | A monitoring device for a municipal water tank. |

| Deep (>10m) | Requires significant engineering: very thick walls, specialized O-rings, and high-torque fasteners. | A subsea data logger or a piece of deep-well monitoring equipment. |

When a client comes to PUMAYCASE needing an IP68 enclosure, my first questions are always "How deep?" and "For how long?". This dialogue is essential. It ensures we select the right aluminum extrusion profile, design the end plates with the correct thickness, and specify a gasket that can handle the pressure. We provide this transparency so that when you receive our enclosure with an IP68 validation report, you know precisely the conditions it's proven to handle.

Conclusion

Creating a true IP68 enclosure is a process of precise design and rigorous testing. By understanding the specific conditions of your application, you can ensure you get a truly waterproof solution.