The Impact of CNC Precision in Aluminum Enclosure Manufacturing?

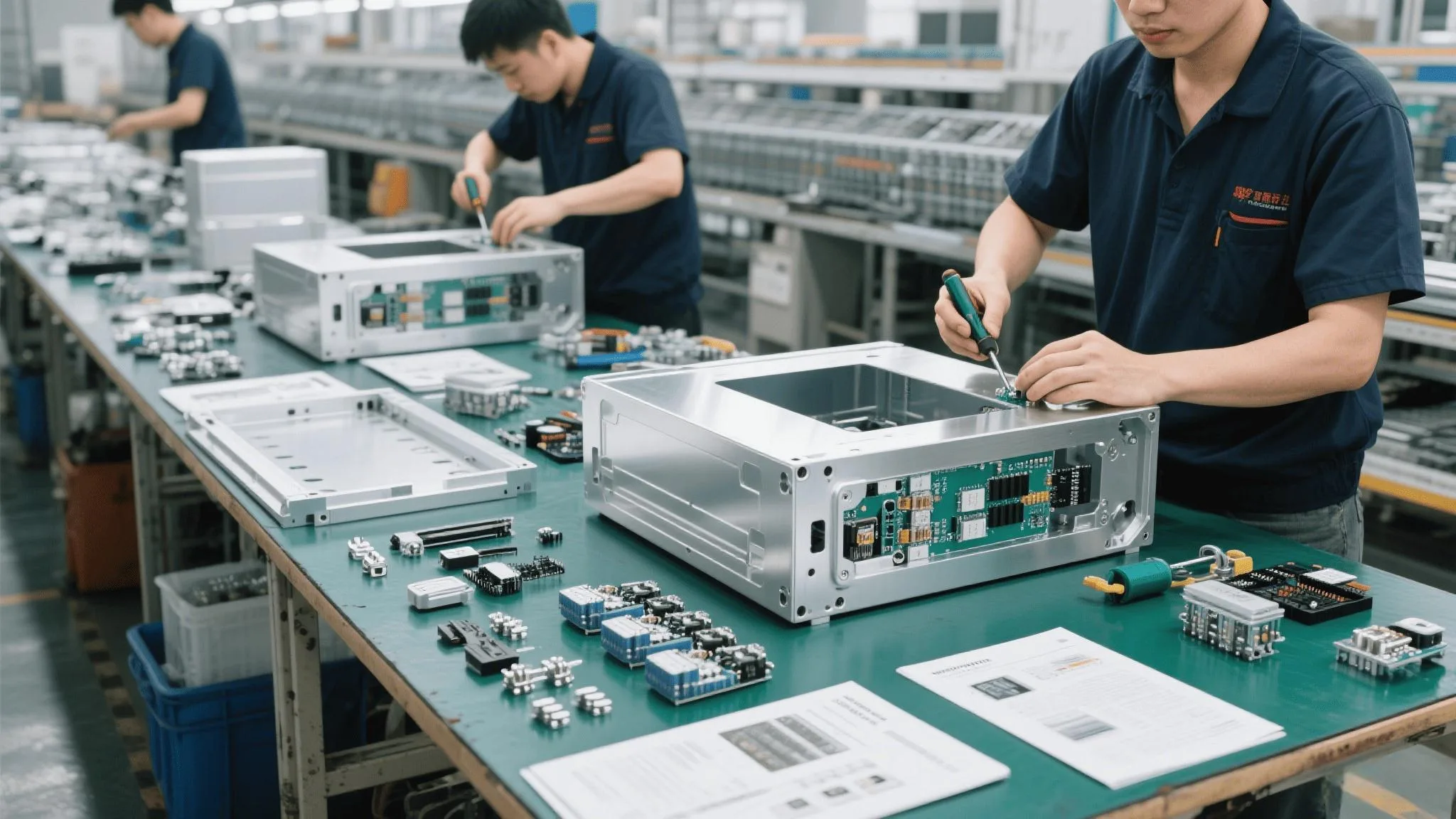

Inaccurate enclosures cause assembly nightmares? Misaligned parts lead to product failures and delays. CNC precision ensures perfect fit and function every time for your critical projects.

CNC precision in aluminum enclosure manufacturing guarantees exact dimensions, intricate features, and consistent quality. This leads to superior fit, enhanced protection, improved aesthetics, and faster assembly for electronic devices.

"CNC Precision in Enclosure Manufacturing")

"CNC Precision in Enclosure Manufacturing")

Now that we see the overall benefit, it’s clear why this matters so much. When I started PUMAYCASE, I knew "Delivering Precision" had to be more than just a slogan; it had to be embedded in our manufacturing process. For engineers like Jeff, who often deal with urgent prototype iterations and complex integrations, the reliability that CNC precision brings is invaluable. It’s the difference between a smooth product launch and a series of frustrating setbacks. Let's explore how this precision makes a tangible difference in various aspects of enclosure manufacturing.

How does CNC precision affect enclosure fit and assembly?

Struggling with parts that don't line up? This wastes valuable time and compromises your final product quality. CNC precision delivers exact cuts for flawless assembly.

CNC precision ensures all holes, cutouts, and mating surfaces on an aluminum enclosure are perfectly dimensioned and positioned. This guarantees components fit correctly, PCBs align as intended, and assembly is smooth and fast.

"Flawless Enclosure Assembly with CNC")

"Flawless Enclosure Assembly with CNC")

Let's dive deeper into this critical aspect. The "fit" of an enclosure isn't just about whether the lid closes easily; it's about how every internal component aligns and integrates within the housing. If these alignments are off, the entire product can be compromised.

The Domino Effect of Imprecision

If a mounting hole for a PCB is off by even a fraction of a millimeter, it can cause a cascade of problems. Connectors might not align with panel cutouts, internal wiring can be stressed or pinched, or boards might not sit flat, leading to potential short circuits or mechanical failures. I've personally seen projects delayed significantly because of such seemingly minor inaccuracies stemming from less precise manufacturing methods used in the past. These delays are frustrating and costly.

CNC: The Key to Interchangeability and Efficiency

CNC machining works directly from digital CAD (Computer-Aided Design) models. This digital-to-physical process minimizes human error and ensures high repeatability.

- Hole Patterns: These are perfectly aligned for standoffs, screws, and other components.

- Mating Surfaces: CNC ensures that surfaces which join together are flat and true, leading to tight, even seals between parts of the enclosure.

- Cutout Accuracy: Openings for connectors, displays, switches, and buttons are machined to exact specifications, ensuring they fit snugly and operate correctly without binding or excessive gaps.

This level of precision means that if you order ten enclosures or a hundred, each one will be dimensionally identical. This consistency is vital for efficient assembly lines and drastically reduces rework or manual adjustments. This is particularly crucial for engineers like Jeff who need rapid customization across many instrument variants; consistent precision is key to their agile development cycles.

| Feature Affected by Precision | Consequence of Imprecision | Benefit of CNC Precision |

|---|---|---|

| Mounting Holes | Misaligned PCBs, stressed components, shorts | Perfect, stress-free component fit |

| Panel Cutouts | Connectors/displays don't fit, look sloppy | Easy, professional installation |

| Mating Edges/Surfaces | Gaps, poor sealing, uneven or forced fit | Tight seals, clean, easy assembly |

| Overall Dimensions | Interference with other systems or housings | Predictable, reliable integration |

What role does CNC play in achieving tight tolerances for aluminum enclosures?

Are loose tolerances ruining your enclosure's performance or aesthetics? This can lead to component damage, sealing failures, or a generally unprofessional product appearance. CNC machining consistently delivers ultra-tight tolerances.

CNC machining is vital for achieving tight tolerances in aluminum enclosures. It uses computer-controlled cutting tools to precisely remove material, ensuring dimensions are consistently within fractions of a millimeter as specified in the design files.

"Achieving Tight Tolerances with CNC")

"Achieving Tight Tolerances with CNC")

Let's dive deeper into tolerances. In manufacturing, "tolerance" refers to the permissible limit or limits of variation in a physical dimension of a part. For PUMAYCASE, our slogan "Delivering Precision" means adhering strictly to the tolerances our clients specify, because we know how critical this is.

Why Tight Tolerances Matter So Much

In the world of electronic enclosures, tight tolerances are not just a "nice-to-have" feature; they are often critical for functionality, reliability, and appearance.

- Sealing Integrity: For achieving specific IP (Ingress Protection) ratings, such as IP67 for dust and water protection, the fit between mating parts and around seals (like gaskets) must be extremely precise. Any deviation can create a path for contaminants. Jeff, our typical product engineer, often needs IP67 sealing for his field instruments.

- Component Fit and Alignment: Modern electronic devices are often densely packed with components. Connectors, printed circuit boards (PCBs), and internal hardware require precise placement and alignment to function correctly and avoid interference.

- Interchangeability of Parts: Parts made with tight tolerances are essentially identical, meaning they can be easily replaced or swapped during assembly or repair without fitting issues.

CNC machines can achieve and consistently hold tolerances that are very difficult, time-consuming, or simply impossible to reach with manual machining methods or less precise automated systems. For example, a typical CNC milling machine can hold tolerances of ±0.05mm (around ±0.002 inches) or even tighter, depending on the machine and process. I've personally seen this level of precision make the crucial difference between a product that passes rigorous environmental and functional testing and one that fails.

Factors Influencing CNC Tolerance Achievement:

To consistently achieve these tight tolerances, several factors must be managed:

- Machine Quality and Maintenance: High-quality, rigid CNC machines that are regularly calibrated and well-maintained are essential.

- Cutting Tool Selection and Condition: Using sharp, appropriate cutting tools for aluminum and replacing them before significant wear occurs.

- Skilled CAM Programming: Optimized toolpaths and cutting parameters generated by experienced CAM programmers.

- Material Stability and Clamping: Using consistent quality aluminum alloy and ensuring the workpiece is securely and correctly clamped during machining to prevent vibration or movement.

Our commitment at PUMAYCASE to provide engineer feedback within 24 hours often involves discussing and confirming these critical tolerances early in the design review process. This helps ensure that project milestones stay intact and that the final product meets all specifications.

| Tolerance Aspect | Importance in Electronic Enclosures | CNC Contribution to Achievement |

|---|---|---|

| Positional Tolerance | Accurate placement of holes, bosses, and other features | Precise X, Y, Z tool path control |

| Dimensional Tolerance | Correct overall size, depth of pockets, cutout dimensions | Consistent and accurate material removal |

| Form Tolerance | Flatness of mating surfaces for seals, straightness of edges | Ability to machine flat, true, parallel surfaces |

| Profile Tolerance | Accuracy of complex curved shapes or contours | Multi-axis machining capability and precision |

Can CNC machining improve the aesthetics and functionality of aluminum enclosures?

Does your current enclosure look clunky or lack essential functional features? Poor aesthetics can diminish product perception, and missing functionality can frustrate users. CNC precision creates sleek designs and smart features.

Yes, CNC machining significantly improves aluminum enclosure aesthetics by creating smooth surface finishes, sharp, clean edges, and intricate design details. Functionally, it enables precise cutouts, accurately engraved markings, and complex integrated features that enhance usability.

"Aesthetic and Functional CNC Enclosures")

"Aesthetic and Functional CNC Enclosures")

Let's dive deeper into how CNC machining elevates both the look and the utility of aluminum enclosures. First impressions matter a great deal, and a well-finished, intelligently designed enclosure speaks volumes about the quality and care invested in the device it houses.

Aesthetic Enhancements Achievable via CNC

CNC machining offers a level of control that directly translates to superior aesthetic qualities:

- Surface Finish Quality: Modern CNC machines, with the right tooling and cutting parameters, can produce very smooth surface finishes on aluminum, minimizing visible tool marks. This provides an excellent, consistent base for subsequent finishing processes like anodizing, powder coating, or painting.

- Chamfering and Radiusing Edges: Precisely machined chamfers (beveled edges) and radii (rounded edges) give an enclosure a professional, modern look and feel. More importantly, they remove sharp burrs, making the enclosure safer to handle.

- Engraving and Marking: Logos, part numbers, instructional text, and even decorative patterns can be accurately and permanently engraved directly onto the aluminum surface using CNC. I've seen beautifully intricate logos that really make a product stand out and reinforce brand identity.

- Complex Contours and Shapes: Multi-axis CNC machines (4-axis or 5-axis) can create aesthetically pleasing curved surfaces, sculpted forms, and complex geometric designs that would be impossible or prohibitively expensive with simpler manufacturing methods.

Functional Improvements Through CNC Precision

Beyond looks, CNC machining adds significant functional value:

- Integrated Features: CNC allows for the precise creation of features like recessed areas for labels or membrane keypads, custom-shaped pockets for specific components, or internal ribs and bosses for added strength or component mounting.

- Precise Ventilation Patterns: Custom ventilation slots or hole patterns can be machined accurately to ensure optimal airflow for cooling sensitive electronics, without unnecessarily compromising structural integrity or EMI shielding.

- Optimized User Interface Elements: Perfect, clean cutouts for buttons, screens, connectors, and LEDs not only look much better but also ensure a more positive user experience with smooth operation and proper alignment.

At PUMAYCASE, we firmly believe an enclosure should be both robust in its protection and elegant in its presentation. Our integrated manufacturing line, which includes CNC machining, anodizing, and silk-screening all under one roof, allows us to deliver enclosures that meet product engineer Jeff's common need for reliable, brand-worthy devices that look as good as they perform.

How does CNC precision impact protection ratings like IP67 in aluminum enclosures?

Worried your enclosure won't pass stringent tests for IP67 sealing? Failures here mean costly damage from water or dust ingress, potentially ruining your electronics. CNC precision is absolutely key to achieving reliable IP ratings.

CNC precision is crucial for achieving IP67 ratings in aluminum enclosures. It ensures the exact dimensions required for gasket grooves, perfectly flat mating surfaces, and accurately placed fasteners, all combining to create the tight seals necessary to prevent dust and water ingress.

"CNC Precision for IP67 Sealing")

"CNC Precision for IP67 Sealing")

Let's dive deeper into the critical world of IP (Ingress Protection) ratings. Achieving a high IP rating like IP67 – which signifies the enclosure is completely dust-tight (the '6') and protected against immersion in water up to 1 meter for 30 minutes (the '7') – is a common and vital requirement for product engineers like Jeff. His field instruments often face dust, moisture, and even accidental submersion. CNC precision is non-negotiable for reliable sealing.

Key CNC Contributions to Achieving IP Ratings:

Several features of an enclosure must be perfectly machined to guarantee a reliable seal:

- Gasket Grooves: The groove that holds the sealing gasket (often an O-ring or a custom profile gasket) must be machined to very precise depth and width. If the groove is too shallow, the gasket won't compress enough; too deep, and it might not compress at all or could be overly compressed. If it's too wide, the gasket might shift; too narrow, and it might be pinched or damaged. I've seen many IP test failures result directly from poorly machined gasket seats.

- Flat and Smooth Mating Surfaces: The surfaces of the enclosure body and lid that compress the gasket must be perfectly flat and smooth. Any deviation, warp, or significant surface irregularity, even if slight, can create a microscopic path for water or fine dust to penetrate. CNC milling excels at creating such true surfaces.

- Lid-to-Base Fit: The overall dimensional accuracy of the enclosure parts ensures a consistent, minimal gap between the lid and base before the gasket is compressed. This ensures the gasket is compressed evenly around its entire perimeter.

- Fastener Hole Positioning and Depth: The holes for screws or bolts that clamp the enclosure parts together must be precisely located and drilled to the correct depth. This ensures even pressure distribution on the gasket when the fasteners are tightened. Uneven pressure can lead to localized seal failure.

PUMAYCASE is proud to offer IP67/IP68 validation reports for many of our enclosure solutions. This confidence stems directly from our investment in high-precision CNC machining capabilities, which can consistently produce parts that meet these demanding sealing requirements. This saves our clients the budget and time for extensive in-house testing.

| CNC Machined Feature | Role in IP67 Sealing | Consequence of Imprecision (leading to IP failure) |

|---|---|---|

| Gasket Groove | Proper gasket compression and retention | Incorrect compression, gasket displacement, leaks |

| Mating Surfaces | Even and continuous pressure on gasket | Gaps, uneven seal, ingress points |

| Lid-to-Base Fit | Minimal initial gap before compression | Uneven sealing pressure, stress points on seal |

| Fastener Holes | Even clamping pressure around the gasket | Localized seal failure due to uneven compression |

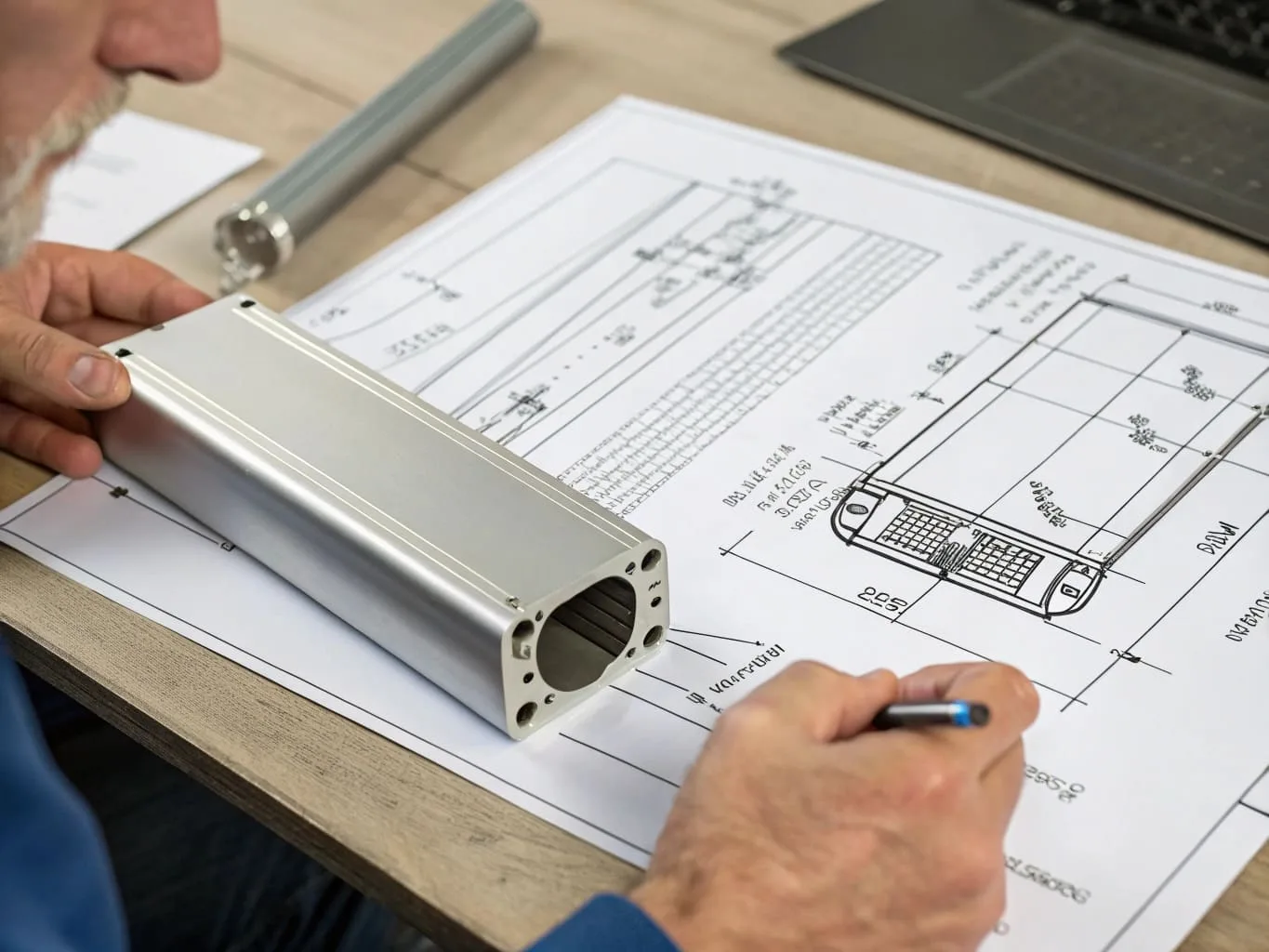

Why is CNC precision crucial for complex aluminum enclosure designs?

Is your innovative and complex enclosure design proving too difficult or expensive to manufacture accurately? Manufacturing challenges can unfortunately derail even the most promising product ideas. CNC precision brings even the most intricate designs to life.

CNC precision is essential for manufacturing complex aluminum enclosures because it can accurately produce intricate external geometries, detailed internal features, thin yet strong walls, and enable multi-part assemblies that would be impossible or cost-prohibitive with traditional methods.

CNC for Complex Enclosure Designs")

CNC for Complex Enclosure Designs")

Let's dive deeper into how CNC machining handles and enables complexity in enclosure design. Modern electronic products are often packed into very specific and sometimes unconventional shapes. These shapes might be driven by the need to fit into tight spaces, unique application requirements, ergonomic considerations, or distinctive aesthetic goals. This is where the capabilities of CNC machining truly shine.

Handling Intricate Geometries and Internal Details

- Multi-Axis Machining: Advanced 3-axis, 4-axis, and even 5-axis CNC machines can create complex curves, undercuts, angled surfaces, and non-orthogonal features that are integral to many advanced enclosure designs. This allows for far more design freedom than simpler 2.5D operations.

- Internal Features: Beyond the outer shell, CNC can precisely machine complex internal walls, separate compartments for shielding or organization, integrated mounting bosses for PCBs or other components, and intricate pathways for optimized airflow or neat cable management. I've worked on designs for clients with internal structures that looked like intricate mazes, all perfectly realized by our CNC capabilities.

- Thin Walls and Fine Details: CNC machining can produce enclosures with surprisingly thin, yet structurally sound, walls to save weight and valuable internal space. It can also machine very fine aesthetic or functional details, such as micro-textures or tiny locating pins, with high accuracy.

Enabling Modular, Integrated, and Rapidly Customized Designs

At PUMAYCASE, we leverage the power of CNC precision to offer solutions like our standard extrusions combined with modular, CNC-machined end plates. This concept relies heavily on the CNC's ability to perfectly customize those end plates with specific cutouts and features, and also to make any necessary precise modifications to the standard extrusion bodies. This allows engineers like Jeff to achieve rapid customization for his many instrument variants without the long lead times or high costs associated with fully custom tooling for each minor variation. The precise interface between the extruded body and the CNC-machined end plates is absolutely critical for a good fit, a reliable seal, and a professional appearance. This versatile "plug-and-play" platform approach can cut development time by as much as 40%, a huge benefit in today's fast-paced markets. Our 4,500 m² integrated manufacturing line, with CNC machining at its core, is specifically designed to handle these complex and customized designs efficiently and accurately.

Conclusion

CNC precision isn't just a manufacturing feature; it's fundamental to quality. It ensures your aluminum enclosures protect reliably, assemble easily, and look professional, truly enclosing innovation.