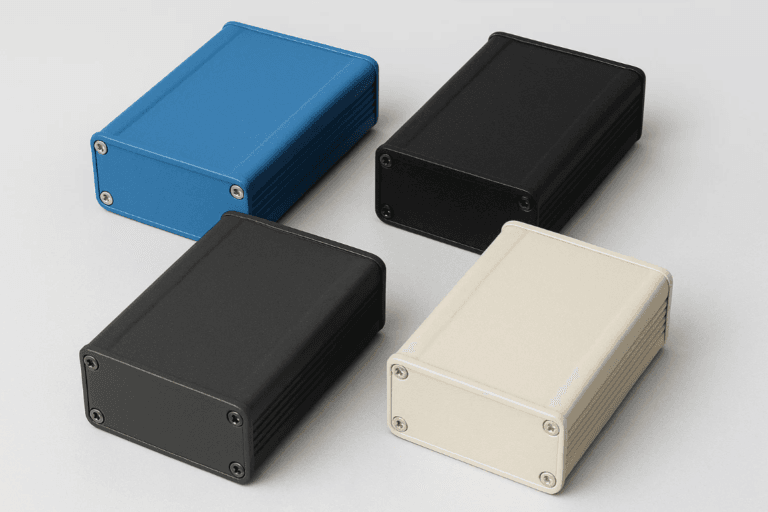

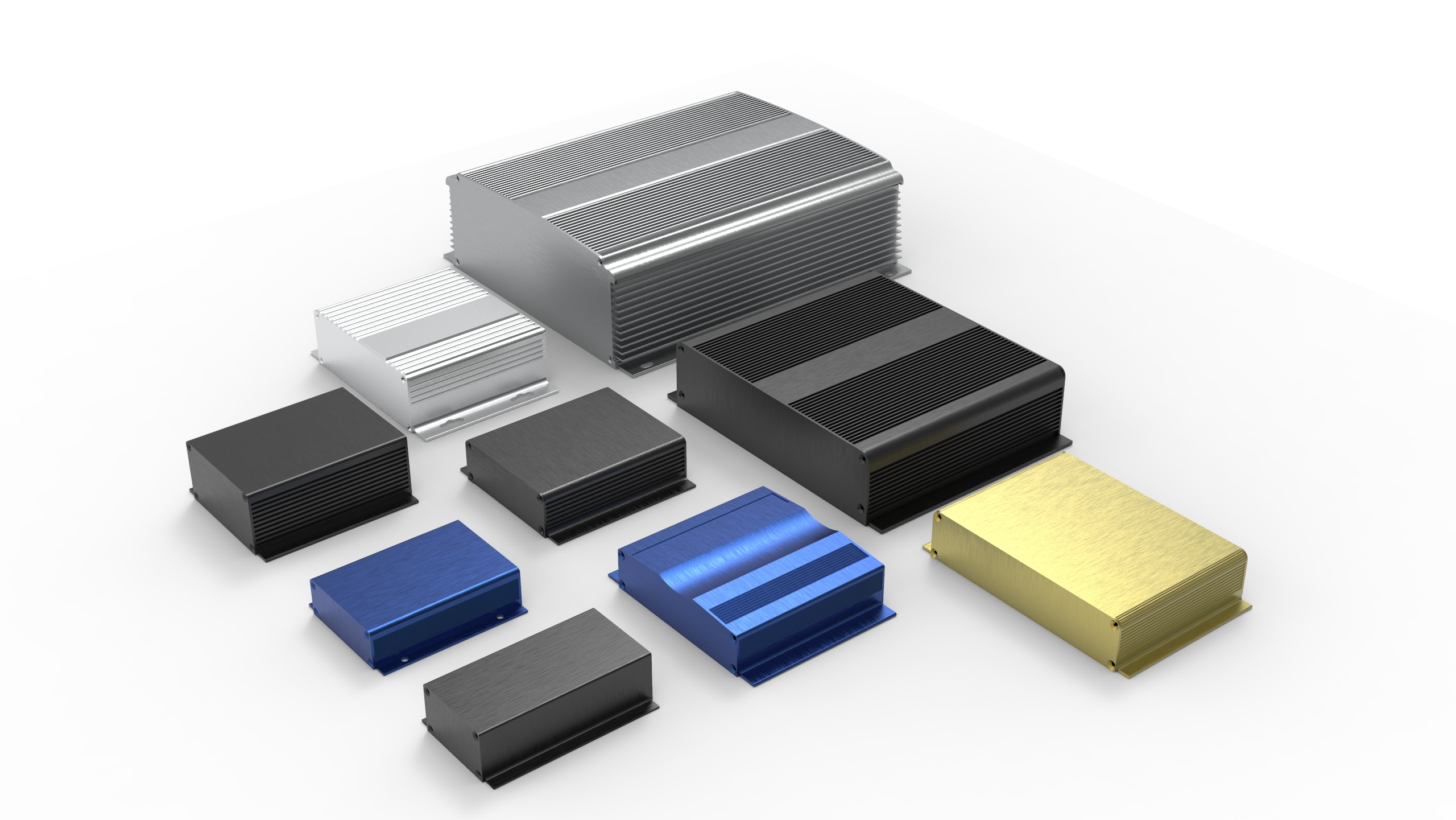

Concerned about aluminum enclosure corrosion1 or poor aesthetics? Untreated aluminum enclosures quickly deteriorate, reducing product reliability and customer confidence.

Effective surface treatments2 like anodizing3, powder coating4, and chemical conversion coating5 enhance aluminum extrusion enclosures’ corrosion resistance6, surface durability7, aesthetics, and thermal performance8, significantly improving product lifespan and visual appeal.

"Surface Treatment Methods for Aluminum Extrusion Enclosures"

"Surface Treatment Methods for Aluminum Extrusion Enclosures"

I've seen many aluminum enclosure projects face premature failures due to inadequate surface treatments. Let's explore key surface treatment methods ensuring optimal durability and aesthetics.

Why is anodizing the best choice for aluminum extrusion enclosures?

Noticing corrosion, fading, or scratches on your aluminum enclosures? Skipping anodizing leaves aluminum vulnerable, affecting both appearance and long-term reliability.

Anodizing creates a protective oxide layer that enhances corrosion resistance, surface hardness, thermal performance, and aesthetics, making it ideal for industrial, outdoor, and electronic aluminum extrusion enclosures.

"Anodizing for Aluminum Extrusion Enclosures"

"Anodizing for Aluminum Extrusion Enclosures"

Throughout my career, anodizing has consistently proven to be the most reliable surface treatment. This electrochemical process converts aluminum surfaces into a durable oxide layer, significantly improving durability, corrosion resistance, and aesthetic options such as color and finish.

Key benefits of anodizing:

- Excellent corrosion protection.

- Enhanced abrasion and scratch resistance.

- Attractive, customizable finishes (color, matte, glossy).

- Increased emissivity for improved thermal performance.

Comparison of anodizing types:

| Anodizing Type | Thickness | Durability | Application |

|---|---|---|---|

| Type II | 5–25 µm | Good | General-purpose, aesthetic |

| Type III (Hard) | 25–75 µm | Excellent | Industrial, harsh environments |

For most aluminum enclosures, Type II anodizing is ideal, offering a balance between cost, aesthetics, and performance.

How does powder coating benefit aluminum extrusion enclosures?

Are you frustrated with inconsistent finishes or limited color choices for your aluminum enclosures? Powder coating provides excellent protection and broad customization options.

Powder coating delivers durable, uniform finishes, excellent corrosion resistance, UV stability9, and vast color customization options, significantly enhancing the appearance and durability of aluminum extrusion enclosures.

"Powder Coating for Aluminum Extrusion Enclosures")

"Powder Coating for Aluminum Extrusion Enclosures")

I've worked with projects where powder coating significantly improved customer perception and product durability. Powder coating involves electrostatically applying dry powder to aluminum surfaces, then curing at high temperatures, resulting in robust protective finishes.

Key advantages of powder coating:

- Excellent corrosion resistance.

- Vast range of color and texture options.

- Consistent, uniform coating coverage.

- UV-resistant, maintaining aesthetics over time.

Comparison between anodizing and powder coating:

| Surface Treatment | Corrosion Resistance | Color Options | UV Resistance | Cost Impact |

|---|---|---|---|---|

| Powder Coating | High | Extensive | High | Moderate |

| Anodizing | High | Limited | Moderate-High | Moderate |

Powder coating is particularly beneficial where aesthetic customization and durable finishes are priorities.

What role does chemical conversion coating play in aluminum enclosure protection?

Experiencing adhesion issues or inconsistent corrosion protection in your aluminum enclosure coatings? Chemical conversion coating provides essential surface preparation and protection.

Chemical conversion coatings (chromate, alodine) enhance aluminum surface corrosion resistance, promote paint adhesion, and serve as an effective base layer before subsequent coatings, significantly improving overall coating performance.

"Chemical Conversion Coating for Aluminum Extrusion Enclosures")

"Chemical Conversion Coating for Aluminum Extrusion Enclosures")

From my experience, chemical conversion coatings are essential preparation methods for optimal paint adhesion10 and corrosion resistance. This process chemically alters the aluminum surface, improving bonding characteristics for subsequent coatings like paint or powder coating.

Benefits of chemical conversion coating5s:

- Improved corrosion protection (short-term, moderate conditions).

- Enhanced paint adhesion10.

- Cost-effective surface preparation.

Comparison with other treatments:

| Surface Treatment | Corrosion Resistance | Adhesion Improvement | Cost Impact |

|---|---|---|---|

| Chemical Conversion | Moderate | Excellent | Low |

| Anodizing | High | Good | Moderate |

| Powder Coating | High | Good | Moderate |

Chemical conversion is ideal for applications requiring reliable base-layer corrosion protection and excellent coating adhesion.

Can polishing and brushing11 enhance aluminum enclosure aesthetics?

Looking for premium finishes to boost the aesthetic appeal of your aluminum enclosures? Polishing and brushing techniques significantly enhance visual attractiveness.

Polishing and brushing methods enhance aesthetics by creating attractive, uniform finishes on aluminum extrusion enclosures, often combined with anodizing or clear coatings to maintain appearance and protection over time.

"Polishing and Brushing Techniques for Aluminum Enclosures"

"Polishing and Brushing Techniques for Aluminum Enclosures"

I've seen many high-end products significantly improve marketability with polished or brushed finishes. Polishing provides a shiny, reflective surface, ideal for premium electronics. Brushing delivers a textured, matte finish, hiding fingerprints and minor scratches, popular in consumer electronics.

Comparison of finishes:

| Finish Type | Appearance | Durability | Typical Application |

|---|---|---|---|

| Polishing | Reflective, premium | Moderate | High-end electronics |

| Brushing | Matte, stylish | High | Industrial, consumer electronics |

Typically, polished or brushed surfaces are combined with anodizing or clear coatings to maximize appearance and durability.

Conclusion

Implementing appropriate surface treatments—such as anodizing, powder coating, chemical conversion, and polishing/brushing—significantly enhances durability, corrosion resistance, aesthetics, and market appeal of aluminum extrusion enclosures.

Understanding the causes of corrosion can help you prevent it and ensure the longevity of your aluminum enclosures. ↩

Explore various surface treatments to enhance the durability and aesthetics of aluminum products. ↩

Anodizing is crucial for protecting aluminum; learn how it enhances durability and appearance. ↩

Discover how powder coating can improve the look and longevity of aluminum enclosures. ↩

Learn about chemical conversion coatings and how they prepare aluminum surfaces for better adhesion. ↩ ↩

Find out how anodizing significantly enhances corrosion resistance in aluminum products. ↩

Understanding surface durability can help you choose the right treatments for your aluminum enclosures. ↩

Explore the impact of anodizing on thermal performance, crucial for electronic applications. ↩

Understand how powder coating protects aluminum from UV damage, maintaining its aesthetics over time. ↩

Learn about methods to enhance paint adhesion on aluminum, ensuring better coating performance. ↩ ↩

Explore how polishing and brushing can elevate the aesthetic appeal of aluminum enclosures. ↩