Your high-performance SAWbird filter is failing to deliver clean signals. Unwanted noise and physical fragility can compromise your entire radio frequency project, wasting time and money.

A reliable enclosure is essential for SAWbird filters1 to provide critical electromagnetic interference (EMI) shielding2, robust physical protection against shock and moisture, and effective thermal management3. These protections ensure the filter operates at its peak performance and survives in real-world conditions.

"SAWbird Filter in Protective Enclosure")

"SAWbird Filter in Protective Enclosure")

Now that we've established the need, let's look at the reasons why. My slogan for PUMAYCASE is "Enclosing Innovation, Delivering Precision," and it applies perfectly here. I've worked with many product engineers like Jeff who deal with highly sensitive RF components. A SAWbird filter is a marvel of engineering, but it's also incredibly delicate. Leaving it exposed is like sending a concert violinist on stage without their instrument case. The slightest electrical noise or physical bump can throw it off-key. A properly designed enclosure isn't just a box; it's an integral part of the system that guarantees the filter can do its job correctly.

What is a SAWbird filter?

Struggling with the technical term "SAWbird filter"? This jargon can be a barrier to understanding a key component in modern radio frequency (RF) systems4.

A SAWbird filter is a compact electronic device that uses Surface Acoustic Waves (SAWs)5 to filter radio frequencies. It allows desired signals to pass through while blocking unwanted noise, improving signal clarity.

"How a SAW Filter Works")

"How a SAW Filter Works")

Let's dive deeper into what makes these devices special. The "SAW" stands for Surface Acoustic Wave. The core of the filter is a special piezoelectric crystal substrate, like quartz or lithium niobate. Think of this crystal like the surface of a pond. An input transducer converts the electrical RF signal into a tiny mechanical wave—a ripple—that travels across the crystal's surface. A second transducer at the other end is designed to "catch" only the ripples of a specific frequency and convert them back into an electrical signal. All other frequencies (the unwanted noise) don't fit the transducer's pattern and are rejected. This method allows for very precise, stable, and small filters, which is why they are so popular. "SAWbird6" is a brand name, often associated with NooElec, that has become popular among Software Defined Radio (SDR) enthusiasts for high-quality SAW filters combined with low-noise amplifiers (LNAs).

| Feature | Description | Benefit |

|---|---|---|

| Technology | Surface Acoustic Wave (SAW) | High precision and stability |

| Core Material | Piezoelectric Crystal | Enables electro-mechanical conversion |

| Function | Band-pass filtering | Selects desired frequencies, rejects noise |

| Size | Very compact and lightweight | Ideal for small and portable devices |

| "SAWbird" | Often includes an integrated Low-Noise Amplifier7 (LNA) | Boosts the filtered signal's strength |

What are SAWbird filters used for?

You know what a SAWbird filter is, but where does it actually get used? Without seeing its real-world applications, its value can seem purely theoretical.

SAWbird filters are primarily used in radio frequency applications to improve signal reception. Common uses include Software Defined Radio (SDR), radio astronomy, GPS receivers, and specialized communication systems.

"SAWbird Filter Applications")

"SAWbird Filter Applications")

Let's dive deeper into these applications. The main goal in any of these fields is to isolate a specific, often weak, signal from a sea of other radio noise.

- Software Defined Radio (SDR): SDR enthusiasts use SAWbird filters to dramatically clean up reception. For example, if you want to listen to a specific satellite frequency, a SAW filter will block strong interference from nearby FM radio stations or cellular towers, making the faint satellite signal audible.

- Radio Astronomy: Scientists trying to detect incredibly faint radio waves from space need to eliminate all possible sources of terrestrial interference. A SAW filter targeted at the specific astronomical band is an essential first line of defense.

- GPS/GNSS: Global Navigation Satellite System signals are extremely weak by the time they reach Earth. A SAW filter helps the receiver lock onto these signals by filtering out much stronger, unwanted frequencies.

- Custom R&D Instruments: Engineers like Jeff often build specialized test equipment. If he is developing an instrument that needs to listen to a specific industrial, scientific, and medical (ISM) band, a SAW filter ensures his device only pays attention to the signals that matter.

At PUMAYCASE, we provide enclosures for these precise applications, ensuring that once the signal is filtered, it's not contaminated again by noise radiating from other nearby components.

| Application | Why a SAWbird Filter is Useful |

|---|---|

| Software Defined Radio | Isolates weak signals from strong local interference. |

| Radio Astronomy | Removes terrestrial noise to detect faint cosmic signals. |

| GPS/GNSS Receivers | Improves signal lock-on by filtering out powerful unwanted signals. |

| IoT Devices | Ensures reliable communication in crowded RF environments. |

| R&D Instruments | Allows for precise measurement of specific frequency bands. |

Why is EMI shielding crucial for SAWbird filters?

Your SAWbird filter isn't performing as expected, and your signal is still noisy. The problem might be invisible electromagnetic interference (EMI) getting past your filter.

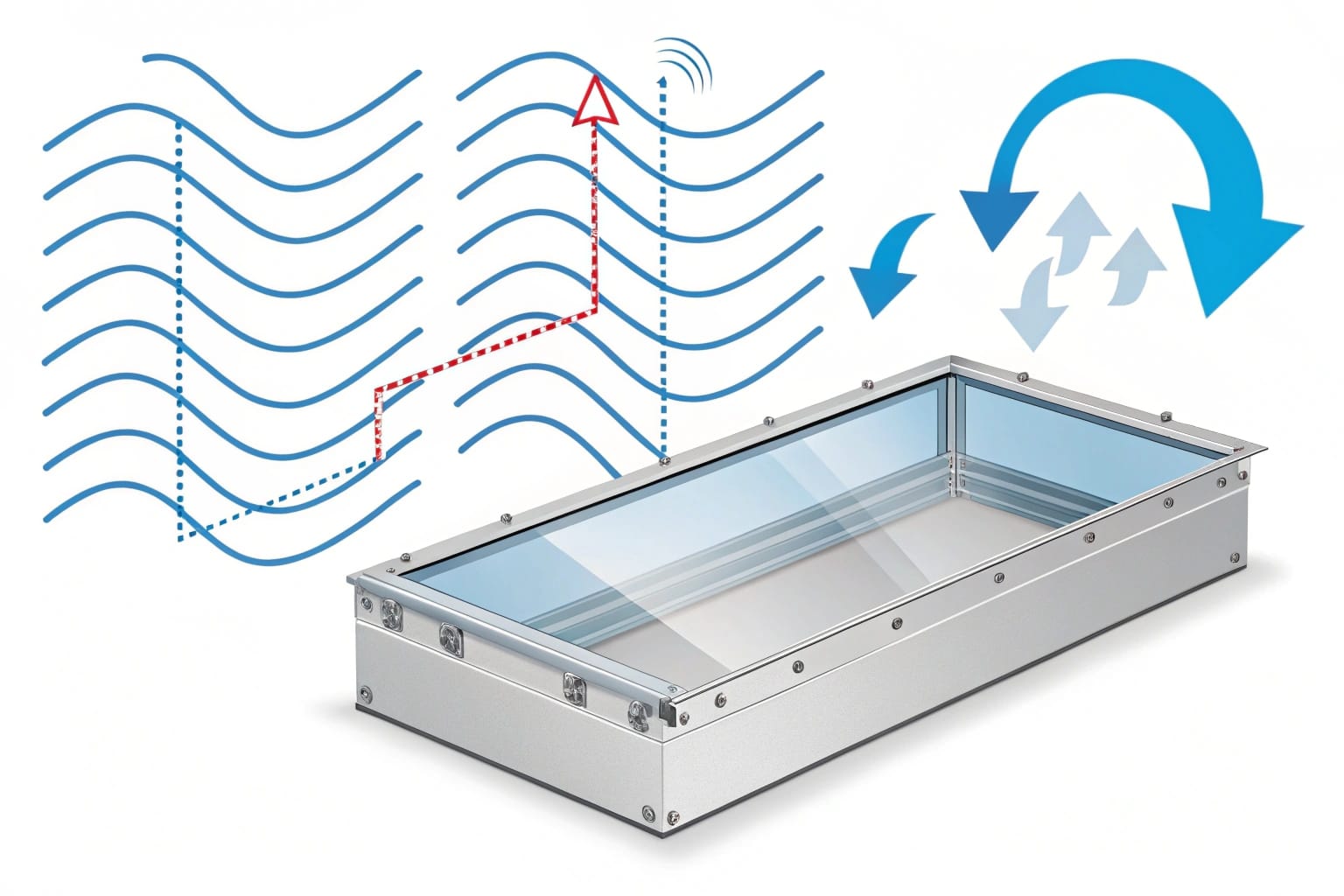

EMI shielding is crucial because SAW filters are highly sensitive to stray radio frequencies. A conductive metal enclosure acts as a Faraday cage, blocking external EMI from corrupting the signal and internal EMI from radiating out.

"EMI Shielding for SAW Filters")

"EMI Shielding for SAW Filters")

Let's dive deeper into this critical topic. Electromagnetic Interference (EMI) is unwanted noise from other electronic devices. Everything from your phone, Wi-Fi router, and microwave oven to nearby power lines generates some level of EMI. A SAW filter is designed to be extremely sensitive to specific frequencies, which means it can also be sensitive to this unwanted noise. If EMI gets into the filter's circuitry, it can raise the noise floor, making it harder to distinguish the desired signal. In some cases, strong EMI can even create false signals, completely invalidating your measurements or reception. A conductive enclosure, like the aluminum ones we make at PUMAYCASE, solves this problem by forming a Faraday cage. This cage intercepts the external EMI and conducts it around the outside of the enclosure to the ground, preventing it from reaching the sensitive components inside. This is one of the most important functions of an enclosure for any RF application. It's a key pain point for engineers like Jeff, who need to ensure the integrity of their sensor data in electronically noisy industrial environments.

How does an enclosure protect SAWbird filters from physical damage?

You've shielded your filter from EMI, but it's still at risk. The delicate internal components of a SAWbird filter can be easily destroyed by a simple drop or vibration.

A robust enclosure provides essential physical protection for the SAW filter's fragile piezoelectric crystal, the printed circuit board (PCB), and all solder joints from shock, vibration, dust, and moisture.

"Physical Protection for Electronics")

"Physical Protection for Electronics")

Let's dive deeper into the physical vulnerabilities. The heart of a SAW filter, the piezoelectric substrate, is a thin crystal that can crack from a sharp impact or excessive vibration. Once cracked, the filter is useless. Furthermore, the filter is mounted on a PCB with other components like connectors and potentially a low-noise amplifier (LNA).

- Shock and Impact: A drop onto a hard surface can easily crack the substrate or break solder joints connecting the filter to the PCB. A solid aluminum enclosure, like ours from PUMAYCASE, absorbs and distributes the force of an impact, protecting what's inside.

- Vibration: For mobile applications or devices mounted on machinery, constant vibration can cause component leads to fatigue and break over time. A rigid enclosure minimizes the flex and movement of the internal PCB.

- Dust and Moisture: Dust can create conductive paths causing short circuits, while moisture leads to corrosion. A well-sealed enclosure with a high IP rating (like our IP67 options) ensures that the SAWbird filter remains clean and dry. For Jeff, who designs instruments for field use, this level of protection is not optional; it's a core requirement for device reliability and longevity.

What makes aluminum the ideal material for a SAWbird enclosure?

You need a protective case, but what material is best for your sensitive SAW filter? Choosing incorrectly can lead to poor performance from EMI, heat, or weight issues.

Aluminum is the ideal material because it offers a perfect combination of properties: it's lightweight yet strong, provides excellent EMI shielding, has great thermal conductivity, and is easily machined for customization.

"Benefits of Aluminum Enclosures")

"Benefits of Aluminum Enclosures")

Let's dive deeper and compare aluminum to other common materials like plastic and steel. When I decided to focus PUMAYCASE on aluminum, it was because of its unique blend of advantages, especially for sophisticated electronics.

- EMI Shielding: Aluminum is highly conductive, creating a natural Faraday cage that is essential for RF components like SAW filters. Most plastics offer zero shielding unless they receive a special, expensive conductive coating.

- Thermal Management: SAW filters and their associated amplifiers (LNAs) generate some heat. Aluminum is an excellent thermal conductor, allowing the entire enclosure to act as a heat sink, passively dissipating heat and keeping the components stable. Plastic is an insulator, trapping heat.

- Strength-to-Weight Ratio: Aluminum is strong enough to provide robust physical protection without adding excessive weight. This is critical for portable devices or anything that needs to be mounted. Steel is stronger, but also much heavier.

- Customization & Cost: Aluminum is easily extruded into complex profiles and then machined for precise cutouts for antennas, power connectors, and LEDs. This allows for rapid customization, a key service we provide.

For an engineer like Jeff, an aluminum enclosure from PUMAYCASE checks all the boxes: it solves the EMI shielding problem, protects against physical damage, manages heat, and can be quickly customized for his prototype iterations.

| Material | EMI Shielding | Thermal Conductivity | Weight | Customization |

|---|---|---|---|---|

| Aluminum | Excellent | Excellent | Low | Excellent (Machining/Extrusion) |

| Plastic | Poor (Needs coating) | Poor (Insulator) | Very Low | Good (Molding) |

| Steel | Excellent | Good | High | Moderate (Harder to machine) |

Conclusion

SAWbird filters are powerful but delicate. A reliable aluminum enclosure is not an accessory but a necessity, providing vital EMI shielding, physical protection, and thermal stability for optimal performance.

Understanding SAWbird filters can help you optimize their performance and mitigate issues like noise and fragility. ↩

Learn about EMI shielding to ensure your projects are protected from unwanted signals that can disrupt performance. ↩

Effective thermal management is crucial for device longevity and performance; explore best practices to enhance your projects. ↩

RF systems are integral to communication technology. Learn more about their workings and importance in today's tech landscape by checking this link. ↩

SAWs play a vital role in modern technology. Discover more about their applications and significance in various fields by exploring this resource. ↩

Discover the significance of SAWbird filters in radio frequency applications and their impact on signal quality. ↩

Learn about Low-Noise Amplifiers and how they enhance signal processing, crucial for high-quality communications. ↩