Your high-performance electronics just failed in the field. It wasn't the circuit design or the firmware — it was an overlooked detail: the box. An inadequate enclosure guarantees that heat, moisture, or interference will find and destroy your hard work.

Industrial enclosures are essential because they provide a complete system of protection that ensures reliability. They actively manage heat, shield against electromagnetic interference (EMI), and provide robust mechanical and environmental defense against hazards like water, dust, and impact, preventing costly failures and extending product life.

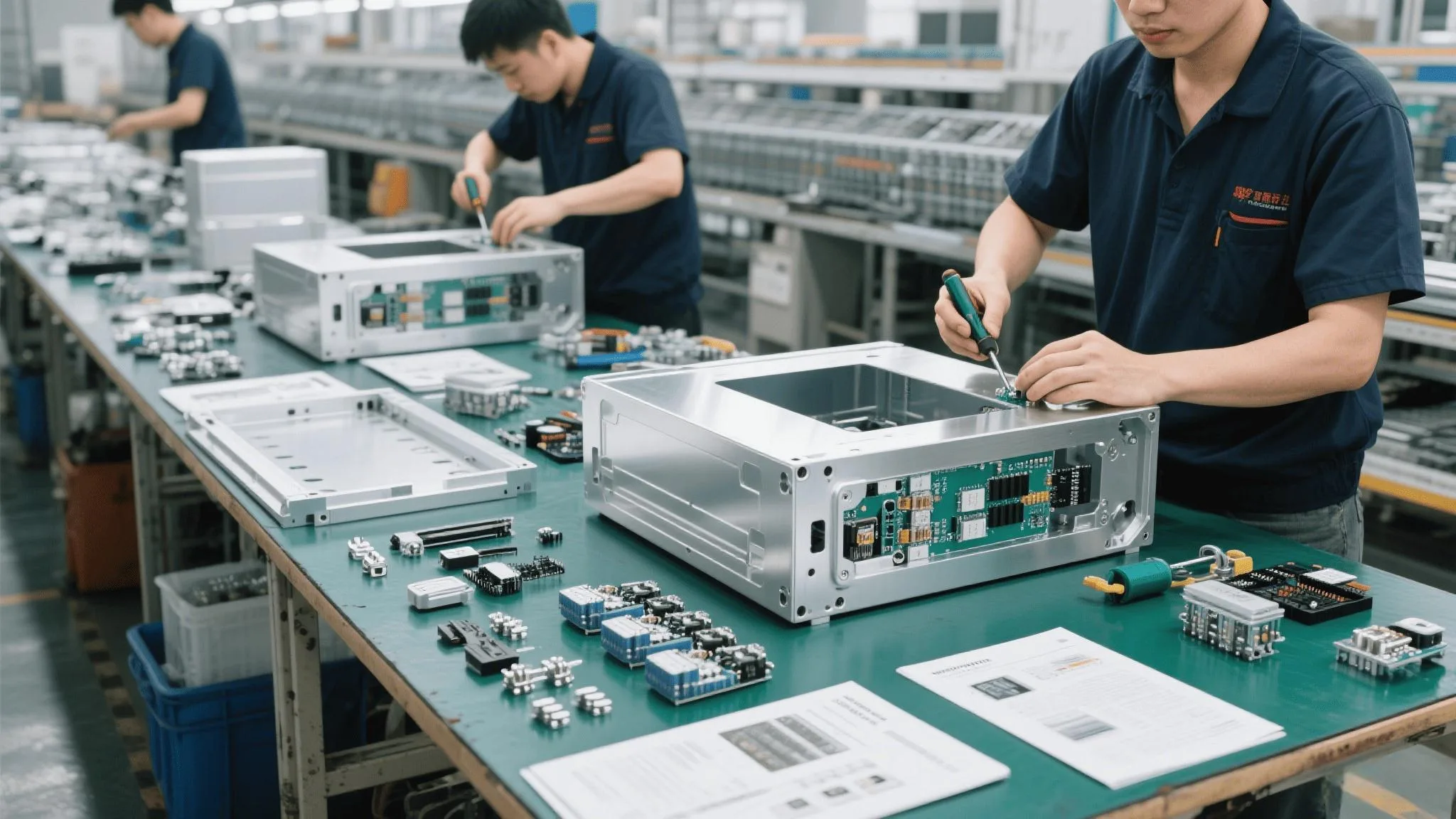

"Industrial equipment enclosure in use"

"Industrial equipment enclosure in use"

Viewing the enclosure as just a container is a common and expensive mistake. Let's explore what separates a simple box from an engineered system designed for survivability.

What makes a good industrial enclosure?

You chose a box that fit the PCB and the budget, but now you're fighting thermal throttling and intermittent EMI issues. A good enclosure isn't passive; it's an active component of your design's success.

A good industrial enclosure is a performance system. It successfully manages three critical domains: thermal (dissipating heat), electrical (shielding EMI/RFI), and mechanical/environmental (providing structural integrity and a certified seal against dust and water).

"Components of a good industrial enclosure"

"Components of a good industrial enclosure"

In my role, I see engineers grappling with failures that originated not on the schematic, but from the physical world outside the PCB. A truly "good" enclosure isn't just about dimensions; it's about solving problems before they happen.

The "Box is a Box" Fallacy

The most dangerous misconception is that the enclosure is a low-value commodity item. An engineer might select a cheap, off-the-shelf plastic case for a power supply controller to save $20 on the BOM, only to find the unit fails after six months in a hot warehouse. Why? The plastic trapped heat, cooking the capacitors and leading to premature failure. The field replacement, labor, and reputational damage cost thousands, all to save a few dollars upfront.

A System-Level View of Enclosure Function

We encourage our clients to think of the enclosure as having three distinct jobs, and we design features to support them:

| Domain | Function | Key Design Features |

|---|---|---|

| 1. Thermal Management | To move heat away from critical components. | Integrated heatsink fins, machined thermal landing pads, proper venting. |

| 2. Electrical Performance | To prevent external EMI from disrupting the circuit and stop the circuit from radiating noise. | Continuous conductive paths, EMC gaskets, minimal apertures. |

| 3. Mechanical/Environmental | To protect against physical impact, vibration, and ingress of contaminants. | Robust wall thickness, IP-rated seals (e.g., IP67), shock-absorbing mounts. |

A good enclosure doesn't just hold your electronics; it keeps them stable, cool, and quiet so they can do their job reliably for years.

What's the difference between a general-purpose box and a true industrial enclosure?

You're browsing supplier catalogs, and the options are overwhelming. A $15 plastic "general-purpose" box looks similar to a $75 "industrial" aluminum enclosure. Why the huge price difference, and when does it actually matter?

Intent and verification. A general-purpose box is designed primarily for containment in a controlled environment. A true industrial enclosure is engineered and tested to mitigate specific, known hazards found in harsh environments like factories, outdoor installations, or vehicles.

"General purpose vs industrial enclosure"

"General purpose vs industrial enclosure"

The difference isn't just marketing; it's a fundamental difference in design philosophy, material science, and manufacturing process. Choosing the wrong one is a recipe for failure.

Field Experience: The Cost of "Good Enough"

I recall a project for an agricultural tech company. They developed a sensor node to monitor soil conditions. To cut costs, their first prototype used a general-purpose ABS plastic box from an electronics hobbyist store. It worked perfectly in the lab. In the field, it failed in less than a month. The thin plastic warped under the hot sun, breaking the seal. Morning condensation then shorted the board.

We replaced it with an IP67-rated, die-cast aluminum enclosure. The robust metal body was immune to thermal warping, and the silicone gasket in a machined groove provided a reliable, long-term seal. The new units have been in the field for years without a single moisture-related failure. The initial "savings" on the plastic box were erased many times over by the cost of the field failures.

Comparison: General-Purpose vs. Industrial Enclosures

| Feature | General-Purpose Box (e.g., ABS Plastic) | Industrial Enclosure (e.g., Aluminum) |

|---|---|---|

| Primary Material | Often plastic (ABS, polycarbonate). | Typically metal (aluminum, stainless steel). |

| Sealing (IP Rating) | None, or a low rating (e.g., IP43). Unverified. | Specified & Tested (e.g., IP66, IP67, IP68). |

| Thermal Management | Insulator. Traps heat. | Conductor. Can act as a passive heatsink. |

| EMI Shielding | None, unless an internal coating is added. | Excellent. The conductive shell forms a Faraday cage. |

| Structural Rigidity | Low. Prone to flexing and impact damage. | High. Resistant to vibration, shock, and impact. |

| Long-Term Stability | Poor. Prone to UV degradation and warping. | Excellent. High stability across temperature ranges. |

A general-purpose box is for a prototype on your bench. An industrial enclosure is for a product you’re willing to stake your company’s reputation on.

What are the ultimate advantages of an engineered enclosure system?

You understand the features, but what is the real business case? How does investing in a better enclosure translate to tangible benefits for your project, your company, and your customers?

The ultimate advantages are increased product reliability and a lower total cost of ownership. By preventing failures, an engineered enclosure system directly reduces warranty claims, protects brand reputation, and accelerates time-to-market by ensuring products pass validation testing the first time.

"Total Cost of Ownership of enclosures"

Investing in a proper enclosure shouldn't be seen as a cost, but as a form of insurance against the far greater costs of failure. The benefits ripple through the entire product lifecycle.

Beyond the "Piece Price": Total Cost of Ownership (TCO)

Engineers are often pressured to reduce the Bill of Materials (BOM), and the enclosure is an easy target. This is short-sighted. The true cost of an enclosure is not its purchase price.

TCO = Initial Price + Integration Cost + Cost of Failure

The "Cost of Failure" is the killer. It includes:

- Redesign & Retesting: The engineering hours and lab fees to fix an EMI or thermal problem.

- Project Delays: The market opportunity lost when your product launch is pushed back by months.

- Field Failures: The cost of shipping replacements, truck rolls for service technicians, and processing warranty claims.

- Brand Damage: The hardest to measure but most damaging cost. A reputation for unreliability is difficult to repair.

A client in the telecommunications space once told me that a single field failure of one of their pole-mounted amplifiers costs them over $2,000 in technician fees and equipment. Spending an extra $50 on a robust, IP67-rated aluminum enclosure with proper thermal management was an incredibly easy decision when viewed through the lens of TCO.

The Advantages Summed Up

An engineered enclosure system delivers:

- Higher Reliability: Fewer field failures and longer product lifespan.

- Faster Time-to-Market: Pass certification (CE, UL, FCC) and environmental tests on the first try.

- Improved Performance: Enables electronics to run cooler and without interference.

- Stronger Brand: Your customers receive a product that feels, and is, robust and dependable.

Conclusion

An industrial enclosure is not a passive box; it is your product's first line of defense and a key performance component. By engineering it to manage heat, EMI, and environmental hazards, you are investing directly in reliability and your customer's success.