Customizing enclosures can elevate your product’s design, improve functionality, and ensure a perfect fit for your components. Partnering with Pumaycase for custom enclosure solutions guarantees a smooth process from concept to delivery.

Our step-by-step collaboration process ensures efficient communication, precision manufacturing, and high-quality results.

Here’s how you can work with Pumaycase to bring your custom enclosure ideas to life.

What Is the Process for Custom Enclosure Collaboration?

The customization process with Pumaycase is straightforward and customer-centered.

Step 1: Initial Consultation and Requirements Collection

Start by reaching out to our team with your project idea and specific requirements.

What we’ll discuss:

- Enclosure size and design preferences

- Material selection (aluminum alloy, stainless steel, plastic, etc.)

- Surface finishing and color options

- Functional needs (cutouts, vents, mounting holes, etc.)

We also encourage you to provide technical drawings, sketches, or reference samples for better accuracy.

Step 2: Design and Feasibility Analysis

Our engineering team reviews your requirements and provides design suggestions to optimize the enclosure.

You will receive:

- A digital mockup for approval

- Material and surface finish recommendations

- Cost estimation and lead time

Step 3: Prototyping (Optional)

For complex projects, we recommend creating a prototype before mass production.

Benefits of prototyping:

- Verify dimensions and fit

- Test material performance

- Make design adjustments if needed

Step 4: Mass Production

Once the design is finalized and approved, we begin production using advanced manufacturing techniques such as CNC machining, laser cutting, and anodizing.

Our quality control team ensures that each enclosure meets your specifications and industry standards.

Step 5: Quality Inspection and Delivery

Before shipping, every enclosure undergoes a thorough inspection to ensure it meets the required standards for size, finish, and functionality.

Shipping options:

- Standard and expedited delivery services

- Global shipping with tracking information provided

Why Partner with Pumaycase for Custom Enclosures?

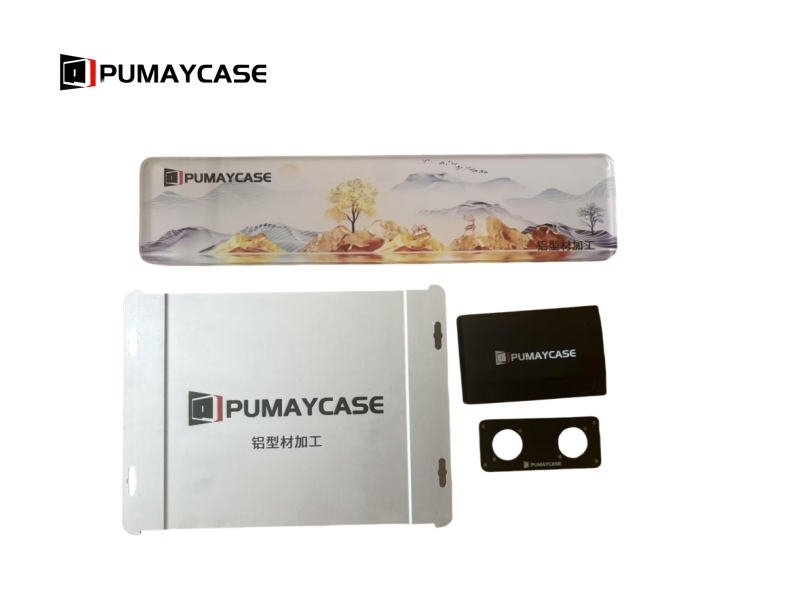

1. Comprehensive Customization Options

We offer a wide range of customization services, including CNC machining, surface treatments, logo engraving, and more.

2. Experienced Engineering Team

Our engineers have extensive experience in designing enclosures for various industries, from electronics to industrial automation and medical devices.

3. Strict Quality Control

We follow international quality standards and conduct thorough inspections at every stage of production to ensure precision and reliability.

4. Fast Turnaround Time

With optimized production processes and reliable logistics partners, we ensure timely delivery of your custom enclosures.

Case Study: Successful Custom Enclosure Collaboration

Client: A renewable energy company\

Project: Custom enclosures for solar inverters

Challenge: The client needed lightweight yet durable enclosures with specific cutouts for cooling vents and cable management.

Solution: Pumaycase provided custom-designed aluminum enclosures with CNC-machined vents and a black anodized finish for improved heat dissipation and corrosion resistance. The project was delivered on time and exceeded the client’s expectations.

Tips for a Successful Collaboration

- Clearly Define Your Requirements: The more detailed your initial input, the better the final result.

- Be Open to Design Suggestions: Our team can offer practical improvements to optimize performance and reduce costs.

- Plan Ahead: Allow sufficient time for prototyping and production, especially for complex projects.

Conclusion

Working with Pumaycase on custom enclosure solutions is a seamless process. From design to delivery, our experienced team ensures your unique requirements are met with precision and quality, helping you bring your products to market with confidence.