Choosing the right panel for your new product is crucial to ensure its functionality, durability, and aesthetic appeal. Whether it’s a control panel for industrial equipment or a front panel for a communication device, the right choice can significantly enhance your product’s performance. At Pumaycase, we specialize in [custom aluminum panels]1(https://americandouglasmetals.com/2024/11/14/how-custom-aluminum-extrusions-revolutionize-product-design/), offering complete customization services tailored to your specific requirements.

In this article, we’ll guide you through the key factors to consider when selecting a panel for your new product.

1. Define Your Product Requirements

Before selecting a panel, it’s essential to understand your product’s specific requirements. Consider the following questions:

- What is the purpose of the panel? Is it for protection, control, or aesthetics?

- What environment will the product operate in? Indoor, outdoor, or harsh industrial settings?

- What type of components will it support? Displays, buttons, connectors, or sensors?

Example:\

For industrial automation systems, the panel must support multiple control buttons and connectors while being resistant to dust and water.

2. Material Selection

The choice of material directly impacts the panel’s durability, weight, and thermal performance. Aluminum is the most popular choice for industrial panels due to its excellent balance of strength, weight, and cost-effectiveness.

Advantages of Aluminum Panels:

- Lightweight and Strong: Reduces overall product weight without compromising durability.

- Corrosion-Resistant: Ideal for outdoor and industrial environments.

- Thermal Conductivity: Helps manage heat generated by electronic components.

- Aesthetic Appeal: Can be anodized, powder-coated, or brushed for a professional finish.

For specialized applications, we offer custom surface treatments to enhance durability and appearance.

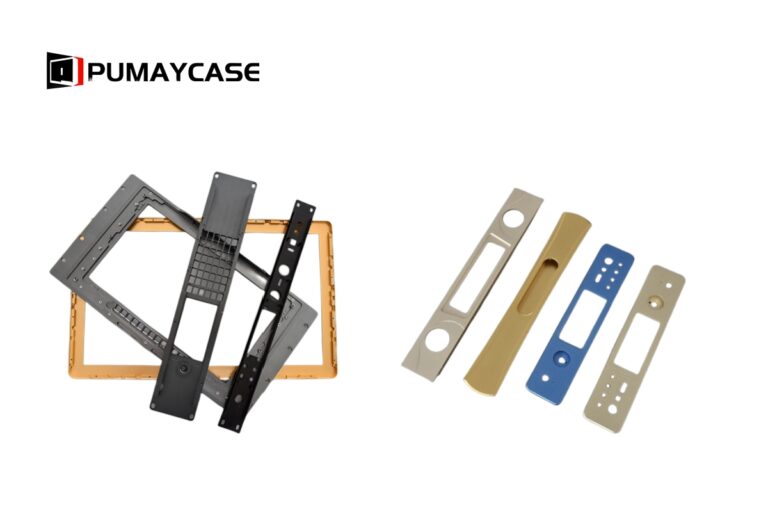

3. Customization Options

Customization is key to making your panel functionally and aesthetically perfect for your product. At Pumaycase, we provide a wide range of [customization options]2(https://support.bigcommerce.com/s/article/Product-Panels):

Size and Dimensions

We can manufacture panels to fit any enclosure size with precise cutouts for switches, connectors, and displays.

Logo Engraving and Printing

Add your company logo or product name for branding and identification.

Options include laser engraving, silk-screen printing, and color-filled engravings.

Surface Finishing

Choose from anodizing, powder coating, and brushing for different looks and protection levels.

Color customization is available for matching your product’s design language.

Custom Cutouts and Engravings

Precision CNC machining allows us to create highly accurate cutouts for connectors, LEDs, and sensors.

4. Consider Environmental and Regulatory Requirements4. Consider Environmental and Regulatory Requirements

Depending on the application, your panel may need to comply with specific industry standards:

IP Ratings: Ensuring protection against dust and water ingress (e.g., IP65, IP67).

EMI/RFI Shielding: Reducing electromagnetic interference for sensitive

-

- EMI/RFI Shielding: Reducing electromagnetic interference for sensitive electronic devices.

- Safety Standards: Panels for medical or industrial use may need to meet certain safety regulations.

Our team at Pumaycase will help ensure that your panel meets the necessary certifications for its intended use.

5. Application Scenarios for Custom Panels

Industrial Control Systems\

Panels with multiple cutouts for switches, connectors, and indicator lights, built for harsh environments.Medical Devices\

Aluminum panels with anodized finishes, providing corrosion resistance and a clean, professional appearance.Telecommunication Equipment\

Custom cutouts for displays, ports, and LEDs, ensuring proper ventilation and heat management.Aerospace and Defense\

Rugged panels with precise engravings for labeling and enhanced durability.

Why Choose Pumaycase for Your Custom Panels?

- High Precision CNC Machining: Achieve micron-level accuracy for even the most complex designs.

- Complete Customization: From size and cutouts to surface finishing and logo printing, we provide tailored solutions.

- Fast Turnaround: Our in-house production lines ensure quick lead times without sacrificing quality.

- Expert Design Support: Need help with your design? Our team will work closely with you to ensure your panel fits perfectly and meets all technical requirements.

- Global Experience: With clients in the U.S., Canada, Europe, and beyond, we understand international standards and requirements.

Conclusion

Choosing the right panel for your new product is a combination of technical requirements, material selection, and customization. At Pumaycase, we help you find the perfect balance to create a panel that meets your functional needs and enhances your product’s appearance.

Ready to get started? Contact us today for a consultation!

Email: [[email protected]]()\

Website: www.pumaycase.com

Let us help you create the perfect panel for your next big innovation!