Worried about enclosure failures? Substandard aluminum can compromise your electronics, leading to costly damage and redesigns. Let's explore how quality is ensured.

Testing an aluminum enclosure's quality involves checking the raw material's alloy and temper, dimensional accuracy after fabrication, surface finish integrity (like anodizing thickness), and specific performance tests like IP rating verification if required.

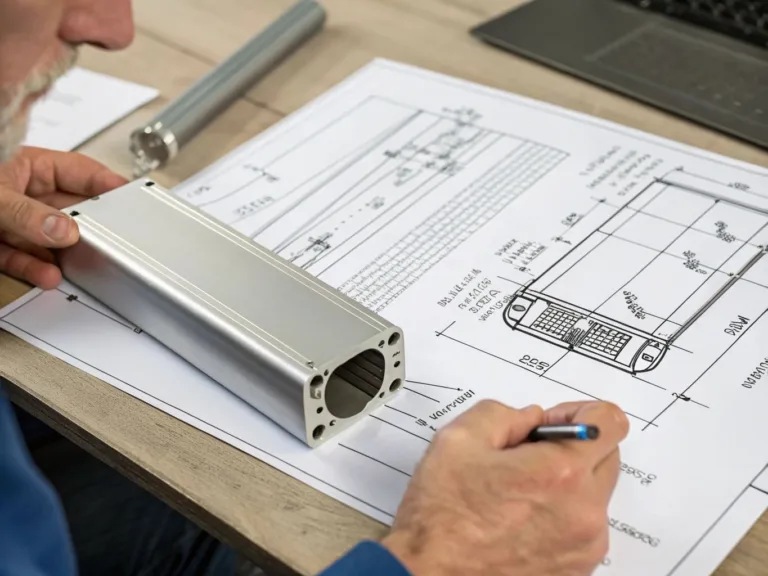

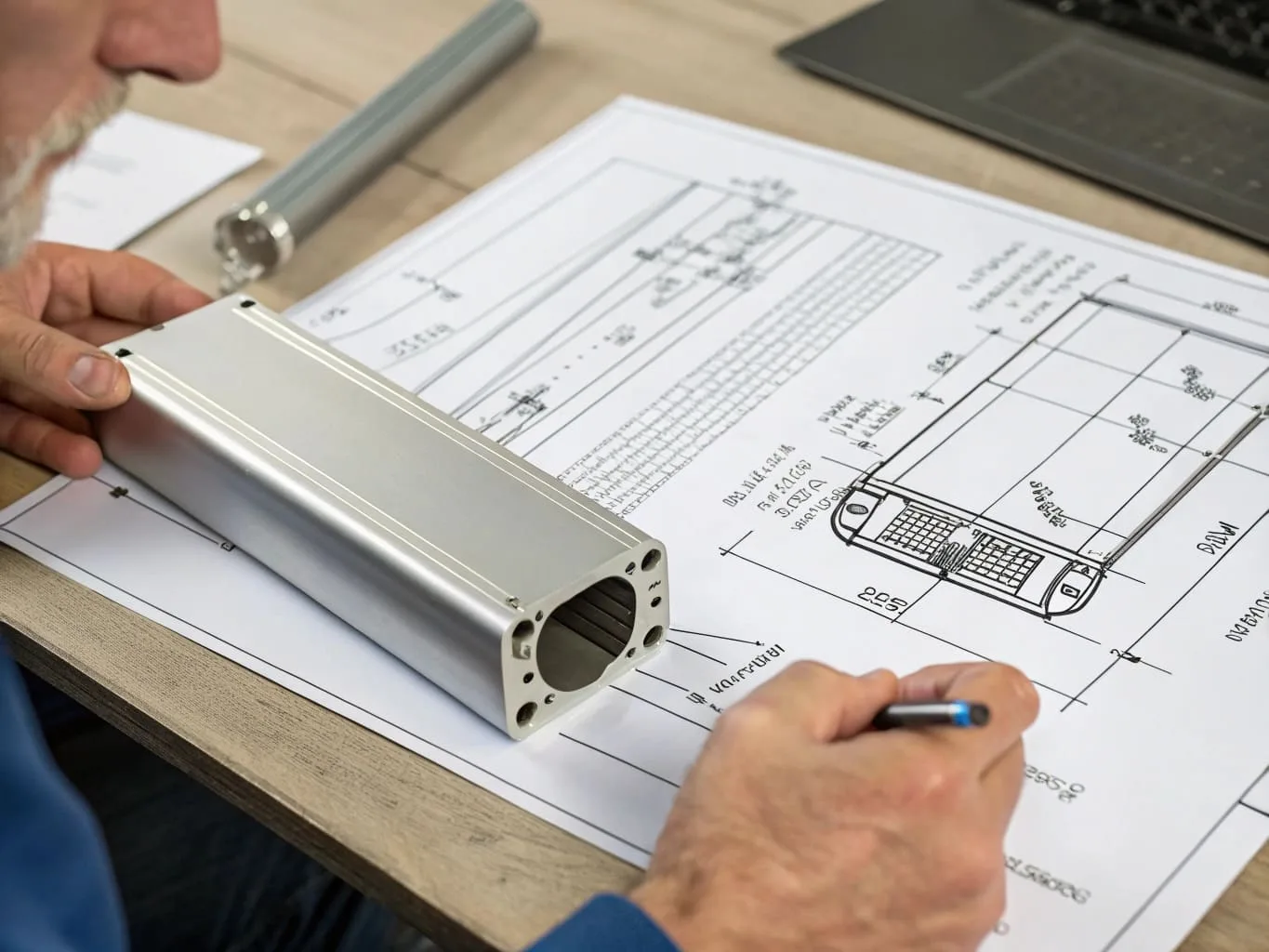

"Aluminum Enclosure Quality Testing")

"Aluminum Enclosure Quality Testing")

Now that you have a general idea, we need to understand that quality isn't just a buzzword; it's a promise. When I started PUMAYCASE, "Enclosing Innovation, Delivering Precision" became our slogan because I saw firsthand how critical enclosure quality is. For engineers like Jeff, getting a perfectly made enclosure means one less thing to worry about. So, let's look at how we ensure the aluminum itself and the final enclosure meet the high standards you expect.

How do you test the quality of aluminum?

Concerned about your aluminum's true grade? Using the wrong alloy or temper can lead to unexpected failures in your product. Let's look at how to verify it.

Aluminum quality is tested through several methods. These include chemical analysis for alloy composition, mechanical tests for strength and hardness, and visual and dimensional inspections for defects and accuracy.

( "Testing Aluminum Quality")

"Testing Aluminum Quality")

Let's dive deeper into these testing methods. I've learned over the years that you can't just take a supplier's word for it; you need processes. When we source aluminum for PUMAYCASE enclosures, we are very particular.

Chemical Composition Analysis1

This is fundamental. You need to know if you have the right alloy, like 6061 or 6063, which are common for enclosures.

- Spectrometry: This is a common method. A small sample of the aluminum is analyzed by a spectrometer. It excites the atoms in the sample and measures the light emitted. Different elements emit light at specific wavelengths, revealing the exact composition and percentage of each element (like magnesium, silicon, copper). This confirms if the alloy matches the specification. I remember a case where a client's previous supplier used an incorrect alloy, and the parts started corroding unexpectedly in a mildly humid environment. Spectrometry would have caught that early.

Mechanical Property Testing2

Aluminum's strength and formability depend on its temper (e.g., T5, T6) and alloy.

- Tensile Testing: A sample is pulled until it breaks. This measures yield strength, ultimate tensile strength, and elongation. These tell you how much force the aluminum can take before it deforms permanently or fractures.

- Hardness Testing: We'll cover this in more detail next. It measures resistance to indentation.

Visual and Dimensional Inspection

- Visual: Checking for surface defects like cracks, porosity, scratches, or discoloration.

- Dimensional: Using calipers, micrometers, or even CMM (Coordinate Measuring Machines) to ensure the raw material (like extrusions or sheets) meets the required size and tolerance specifications.

These tests give us confidence in the raw material before it even hits our CNC machines.

| Test Type | What it Checks | Common Method(s) | Why it's Important for Enclosures |

|---|---|---|---|

| Chemical Composition | Correct alloy elements and percentages | Spectrometry (OES, XRF) | Corrosion resistance, machinability, strength |

| Mechanical Properties | Strength, ductility, hardness | Tensile Test, Hardness Test | Durability, impact resistance |

| Visual Inspection | Surface flaws, consistency | Eye, magnification | Aesthetics, basis for good finish |

| Dimensional Check | Thickness, width, length, straightness | Calipers, CMM | Ensures fit, proper machining later |

What is the hardness test for aluminum?

Is your aluminum strong enough? Without proper hardness, your enclosure might dent or deform easily, failing to protect sensitive components. Let's understand hardness testing.

The primary hardness tests for aluminum3 are Brinell, Rockwell, Vickers, and Webster. Each method uses an indenter to make a mark, and the material's resistance to this penetration determines its hardness value.

"Aluminum Hardness Test")

"Aluminum Hardness Test")

Let's dive deeper into these common hardness tests. At PUMAYCASE, ensuring the aluminum has the correct hardness for its specified temper (like T6 for 6061 aluminum) is crucial. It directly impacts the enclosure's ability to withstand daily wear and tear.

Common Hardness Testing Methods for Aluminum:

Each method is suited for different types of aluminum or application requirements.

Brinell Hardness Test (HB):

Uses a hardened steel or tungsten carbide ball indenter (typically 10mm diameter) pressed into the material with a specific load. The diameter of the resulting indentation is measured. It's good for castings or forgings with coarser grain structures but less suitable for very thin materials.Rockwell Hardness Test (HR):

Measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload. There are various Rockwell scales (e.g., HRB, HRE, HRF, HRH) suitable for aluminum, using different indenters (ball) and loads. It's quick and widely used. For example, HRB is often used for softer aluminum alloys.Vickers Hardness Test (HV):

Uses a diamond square-based pyramid indenter. It produces a square indentation, and the diagonals are measured. Vickers is versatile and can be used for very soft to very hard materials, including thin sheets and case-hardened surfaces. It's often used for precise measurements or on small areas.Webster Hardness Test:

This is a portable, fast method often used for spot checks on aluminum alloys, especially extrusions and sheets. It uses a spring-loaded indenter and gives a direct reading on a dial. It's great for quickly checking if a batch of material meets a minimum hardness requirement on the factory floor. I've used Webster testers many times for quick verification of incoming extrusions.

The choice of test depends on the material thickness, expected hardness range, and the specific standard being followed. For instance, you wouldn't use a heavy-load Brinell test on a thin aluminum sheet for an enclosure.

| Test Method | Indenter Type | Measurement Basis | Typical Aluminum Application | Pros | Cons |

|---|---|---|---|---|---|

| Brinell | Hardened Ball | Indentation Diameter | Castings, forgings, softer alloys | Good for bulk material | Not for thin parts, larger indentation |

| Rockwell | Ball (for Al) | Indentation Depth | Sheets, extrusions, general use | Quick, simple, direct reading | Multiple scales can be confusing |

| Vickers | Diamond Pyramid | Indentation Diagonals | Thin materials, small areas, all alloys | Very accurate, wide range | Slower, requires sample preparation |

| Webster | Specific spring-loaded | Direct Dial Reading | On-site checks, extrusions, sheets | Portable, very fast | Less precise than benchtop methods |

What is the best way to check aluminum?

Searching for a foolproof way to check aluminum? Without a reliable method, you risk using material that won't perform as expected in your enclosures. Let's find a practical approach.

The "best" way to check aluminum combines verifying material certifications (MTRs) with visual inspection for defects, dimensional checks against specifications, and, where critical, spot hardness tests. This multi-faceted approach ensures suitability.

"Best Way to Check Aluminum")

"Best Way to Check Aluminum")

Let's dive deeper into what makes a practical and effective checking process. When Jeff, the product engineer, needs rapid customization for his instrument variants, he can't afford delays due to material issues. So, a "best way" is one that's thorough yet efficient.

For me, the best approach is a risk-based one, focusing on "fitness for purpose."

1. Documentation Review: The First Line of Defense

- Material Test Reports (MTRs) or Certificates of Conformity (CoC): Always start here. Reputable suppliers provide these documents, which detail the chemical composition and mechanical properties (like tensile strength, hardness) of the specific batch of aluminum. This is your primary confirmation that the alloy and temper are what you ordered. I always insist on MTRs for our PUMAYCASE stock.

2. Visual Inspection: Your Eyes are Key Tools

- Surface Condition: Look for scratches, dents, corrosion, stains, or inconsistencies in surface finish (if pre-finished, like anodized or powder-coated material). For enclosures, aesthetics matter, but these can also indicate deeper problems.

- Uniformity: Check for consistency in color and texture, especially for extrusions.

- Edge Condition: For sheets or cut profiles, check for burrs or rough edges.

3. Dimensional Verification: Does it Measure Up?

- Key Dimensions: Use calipers, micrometers, or even profile projectors for extrusions to check critical dimensions against drawings or standards. This is crucial for the precision PUMAYCASE promises. Tolerance mismatches are a huge pain point for engineers.

- Straightness/Flatness: Especially for longer extrusions or larger sheets, ensure they aren't warped or bowed beyond acceptable limits.

4. Simple Non-Destructive Spot Checks (If Applicable)

- Hardness Check: A portable Webster or Barcol impressor can give a quick go/no-go indication of correct temper, especially if there are doubts or if the MTR is generic.

- Spark Test (Less Common for Al, but distinguishes some metals): While not a primary aluminum test, a very experienced eye might distinguish some metals, though this is less reliable for specific aluminum alloys.

- Conductivity Test: Electrical conductivity can sometimes help differentiate between alloy series as different alloys have characteristic conductivity ranges.

The "best" way isn't a single test but a process. It's about gathering enough evidence to be confident the aluminum will perform in the final enclosure.

What is the quality of aluminium metal?

Wondering what "good quality" aluminum truly means? Using inferior metal leads to poor performance, difficult fabrication, and a less durable enclosure. Let's define quality.

The quality of aluminum metal is determined by its specific alloy composition, adherence to temper specifications, mechanical properties (strength, hardness), corrosion resistance, consistency, and surface finish characteristics suitable for its intended application.

"Quality Aluminum Metal")

"Quality Aluminum Metal")

Let's dive deeper into these aspects of aluminum quality. As someone who has built a business, PUMAYCASE, around "Enclosing Innovation, Delivering Precision," the base material quality is non-negotiable. For an engineer like Jeff, high-quality aluminum means his devices are well-protected and look professional.

Key Factors Defining Aluminum Quality:

Alloy Purity and Composition:

The exact mix of alloying elements (like silicon, magnesium, copper, zinc, manganese) defines the alloy series (e.g., 1xxx, 3xxx, 5xxx, 6xxx, 7xxx) and its inherent properties. High-quality aluminum has tight control over these elements and minimizes impurities. For instance, 6061 and 6063 alloys are popular for enclosures due to their good balance of strength, corrosion resistance, and extrudability. Impurities can degrade these properties.Correct Temper:

The temper (e.g., F, O, Hxx, Txx) indicates the heat treatment and/or strain hardening process the aluminum has undergone. This significantly affects its mechanical properties like hardness, strength, and ductility. A T6 temper (solution heat-treated and then artificially aged) for 6061 aluminum provides excellent strength. Using an incorrect temper, say T4 instead of T6, would result in a much softer, weaker enclosure.Consistent Mechanical Properties:

This refers to the aluminum consistently meeting specified values for tensile strength, yield strength, elongation, and hardness across batches. Consistency is vital for predictable performance during manufacturing (machining, bending) and in the final application.Good Surface Finish and Appearance:

For enclosures, the surface is critical. High-quality aluminum should have a smooth, uniform surface free from defects like scratches, pits, die lines (in extrusions), or stains. This ensures good results when anodizing, powder coating, or silk-screening. I've seen how poor surface quality on raw aluminum leads to a terrible final finish.Dimensional Stability and Tolerances:

The aluminum (whether sheet, plate, or extrusion) must meet tight dimensional tolerances. This ensures parts fit together correctly and that features like mounting holes are accurately placed.Machinability and Formability:

Depending on the alloy and temper, good quality aluminum will exhibit predictable behavior during machining (good chip formation, minimal tool wear) or forming operations.Corrosion Resistance:

While aluminum naturally forms a protective oxide layer, the specific alloy and surface treatments (like anodizing) greatly enhance this. Quality means the material performs as expected in its intended environment.

At PUMAYCASE, our integrated manufacturing line relies on starting with high-quality aluminum. It reduces processing problems and ensures the final enclosure delivered to clients meets their expectations for both function and aesthetics.

Conclusion

Ensuring aluminum enclosure quality involves rigorous testing from raw material to finished product. This guarantees durability, precision, and performance for your critical applications.

Understanding chemical composition analysis is crucial for ensuring the right alloy is used, preventing costly failures in your products. ↩

Mechanical property testing is essential for assessing the strength and durability of aluminum, ensuring your enclosures can withstand real-world conditions. ↩

Exploring the various hardness tests for aluminum helps you choose the right method for your specific application, ensuring optimal performance. ↩