Choosing the wrong supplier can ruin your project with delays and poor quality. Imagine receiving a batch of enclosures that don't fit, setting your entire product launch1 back by weeks.

To properly vet a supplier, check their technical feedback2, verify they have in-house manufacturing3, evaluate their communication, order a physical prototype4 first, and confirm they have reliable logistics5 and post-sale support6. These five steps ensure you find a true partner.

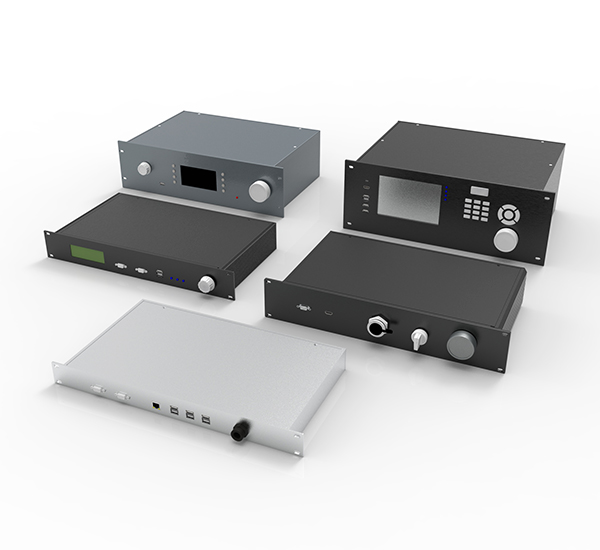

%[A checklist graphic with icons for DFM, factory, communication7, prototype, and logistics] “5 steps to vet a rackmount enclosure supplier”

“5 steps to vet a rackmount enclosure supplier”

Finding the right supplier is about more than just finding the lowest price. It's about finding a partner who will help make your project a success. Over my years in this business, I've seen brilliant projects fail because of a poor supplier choice. A good partner doesn't just sell you a metal box; they invest their expertise in your design to prevent problems before they happen. Let's break down the simple, five-step process I recommend to every engineer I work with.

Can They Offer More Than Just a Price Quote?

You send your technical drawing to a supplier and just get a price back. This lack of engagement means potential design flaws will only show up in the final, expensive product.

A great supplier acts as a technical partner. They must provide a Design for Manufacturability (DFM)8 review with your quote. This feedback, which suggests improvements to quality and cost, is a key sign of their engineering expertise9 and commitment.

“Design for Manufacturability feedback on an enclosure design”)

“Design for Manufacturability feedback on an enclosure design”)

Step 1: Evaluate Their Technical Feedback

The first interaction you have with a potential supplier is the most telling. Do they just want to win the order, or do they want to make your product better? A simple "quote-only" vendor is a red flag. A true manufacturing partner will have their engineers review your design for potential issues. This DFM review is critical. For example, we might see that changing a sharp internal corner to have a slight radius would allow us to use a larger, faster tool, which cuts machining time and saves you money. Or we might notice that a wall is too thin and could warp during the anodizing process. I make sure my team provides this kind of feedback within 24 hours. This isn't about criticizing your design; it's about using our manufacturing experience to ensure the final product is perfect, strong, and as cost-effective10 as possible. This proactive approach prevents the tolerance mismatch issues that engineers like Jeff often face.

| Quote-Only Vendor | Manufacturing Partner |

|---|---|

| Provides price only | Provides price and DFM feedback |

| Ignores potential design flaws | Identifies and suggests improvements for cost and quality |

| Acts as a simple seller | Acts as an extension of your engineering team11 |

| High risk of future problems | Low risk of production errors |

Do They Control Their Own Manufacturing Process?

Your supplier promises a great product, but they outsource key steps like anodizing. This leads to inconsistent quality, mismatched colors, and frustrating delays as they blame subcontractors for problems.

You must ask if they handle core processes in-house. A supplier with integrated manufacturing—CNC machining, surface finishing, and printing under one roof—can guarantee quality, meet deadlines, and take full responsibility for the final product.

%[An integrated factory floor showing CNC machines, anodizing tanks, and a silk-screening station](https://placehold.co/600x400 “Integrated manufacturing for enclosures”)

Step 2: Verify In-House Manufacturing

This is a huge one. I started PUMAYCASE with an integrated manufacturing12 line for a reason. I saw too many projects get stuck in a loop of blame between separate machining shops and finishing shops. The machine shop would deliver parts, the anodizer would say the surface prep was wrong, and the client would be caught in the middle with a delayed project. When a supplier controls every step, they own the outcome. There's no finger-pointing. We take the raw aluminum extrusion and it doesn't leave our control until it's a fully finished, printed, and assembled enclosure ready for packaging. This allows us to control the quality at every single stage. For an engineer like Jeff, who needs to avoid tolerance issues13 from multiple vendors, this is the only way to guarantee that the part you get is exactly the part you designed. It is the single biggest factor in ensuring reliable lead times and consistent quality.

| Outsourced Model | Integrated Model |

|---|---|

| Higher risk of delays and communication errors | Faster lead times and clear communication |

| Inconsistent quality between batches | Consistent quality and finish every time |

| Blame is passed between vendors | A single point of contact and responsibility |

| Difficult to control tolerances | Tight control over all manufacturing tolerances |

How Can You Test Their Quality Before a Full Production Run?

Committing to a large order based on a 3D model on your screen is a big risk. What if the finish isn't what you expected, or your components don't fit perfectly?

Always order a physical prototype4 first. A confident supplier will encourage this. A single, fully-finished sample allows you to test the fit, feel the finish, and validate every detail before committing to a larger production run.

“Testing a physical prototype enclosure”

“Testing a physical prototype enclosure”

Step 3: Always Order a Prototype

I tell my clients that the money they spend on a prototype is the best insurance policy they can buy for their project. A 3D model can't tell you how a finish feels in your hand, or give you that 100% confidence that every connector and mounting hole is perfect. A prototype isn't just a 3D print; it must be made using the exact same machines, materials, and finishing processes as your final production run. This is the ultimate test of your supplier's capability. For engineers like Jeff dealing with urgent prototype iterations, a supplier's ability to produce a high-quality sample quickly is a massive advantage. We leverage our standard extrusion platforms to deliver prototypes up to 40% faster. This allows you to get a physical part in your hands, test it with your real components, and give the final "go-ahead" with absolute certainty, avoiding any costly surprises on the main order.

Is Their Communication Clear and Responsive?

You send a critical question and wait days for a vague reply. This communication gap, especially across time zones, can grind your project to a halt and create massive uncertainty.

Test their communication from your very first inquiry. A good partner responds within 24 hours with clear, helpful answers from someone technical. This initial experience is the best indicator of the support you'll receive for the entire project.

“Clear and responsive supplier communication”

“Clear and responsive supplier communication”

Step 4 & 5: Evaluate Communication and Support

These last two steps are about the human element. From your first email, are they helpful? Do they answer your questions directly? At PUMAYCASE, we promise engineer-to-engineer feedback within 24 hours because we know that transparent technical communication is key. A good partner doesn't just respond; they understand the intent behind your question and provide solutions. This extends all the way to logistics5 and after-sales support. A great supplier doesn't consider the job done when the enclosure is manufactured. They make sure it's packaged securely to prevent damage and they provide you with clear tracking information. They help you navigate customs and are ready to solve any problems that might arise after delivery. Their job ends only when you have a perfect product in your hands and are completely satisfied. That continuous support is the final, crucial sign of a supplier you can trust for the long term.

Conclusion

Vetting a supplier isn't about price. It’s about finding a partner with technical expertise, integrated quality control14, and excellent communication who will ensure your project's success from start to finish.

Understanding the factors that contribute to a successful product launch can help you avoid common pitfalls. ↩

Understanding technical feedback can help you choose a supplier that enhances your product quality. ↩

In-house manufacturing ensures quality control and reduces delays, making it vital for project success. ↩

A physical prototype allows you to test and validate designs before full production, reducing risks. ↩ ↩

Reliable logistics are crucial for timely delivery and project continuity, impacting overall success. ↩ ↩

Post-sale support ensures ongoing assistance and satisfaction, crucial for long-term supplier relationships. ↩

Clear communication is key to project success, ensuring timely responses and effective problem-solving. ↩

DFM can significantly improve product quality and cost, making it essential for effective supplier partnerships. ↩

Suppliers with engineering expertise can provide valuable insights that enhance product design and quality. ↩

Suppliers that focus on cost-effectiveness can help you save money while maintaining quality. ↩

A supplier that collaborates closely with your engineering team can enhance product development and innovation. ↩

Integrated manufacturing streamlines production, ensuring consistency and reducing delays. ↩

Understanding tolerance issues helps prevent costly mistakes and ensures product compatibility. ↩

Effective quality control practices are essential for maintaining product standards and customer satisfaction. ↩