You have a critical project, but choosing a new enclosure supplier feels like navigating a minefield. Pick wrong, and you're facing months of delays and thousands in sunk costs.

To spot a reliable partner in a 20-minute call, you must move beyond price. Ask targeted questions about their Design for Manufacturability (DFM) process1, demand proof of material traceability2, and see case studies of projects with similar thermal or EMC challenges3 to yours.

"Vetting an aluminum enclosure supplier"

"Vetting an aluminum enclosure supplier"

This isn't just about vetting a vendor; it's about qualifying an engineering partner4. Here are the questions that separate the experts from the simple machine shops.

How Can I Verify Their Material and Finish Quality?

Your drawing specifies Aluminum 6061-T6 for its strength, but a cheaper supplier’s quote seems too good to be true. How do you ensure you aren’t getting a weaker, less durable alloy?

Ask for a sample material traceability certificate and inquire about their specific process controls for surface finishing. A quality-focused supplier can immediately explain their supply chain verification5 and how they guarantee consistent anodizing thickness6 or powder coat adhesion7.

"Aluminum material quality certificate"

"Aluminum material quality certificate"

The material you spec is not a suggestion; it's a core functional requirement. The difference between alloys isn't just a line on a datasheet—it has real-world consequences for your product's reliability.

Not All Aluminum is Created Equal

A common mistake I see is an engineer approving a quote without confirming the specific alloy and temper. A supplier might substitute 6063 for 6061 to lower their costs. While 6063 is great for complex extruded profiles, it has roughly half the yield strength of 6061-T6. For a rackmount chassis supporting heavy internal components, that substitution can lead to warping or outright failure during shock and vibration testing8.

Case Example: The Failed Vibration Test

A client in the telecommunications space came to us after their 1U radio unit failed vibration testing8. The mounting flanges on their enclosure, made by a different supplier, were physically deforming. We analyzed the material and found it was a softer, unspecified 5000-series alloy—likely chosen because it was cheap and easy to form. We remade the enclosure using the originally specified 6061-T6, and it passed with no issues. The few dollars they "saved" on the material cost them six weeks of schedule delays and re-testing fees.

Your 5-Minute Material Quality Checklist

Ask these questions on your call:

- "What is your process for material verification?" (Look for answers like "We require material certs from our suppliers for every batch" not "We trust our supplier.")

- "Can you provide full material traceability2 with a production order?" (The answer should be a confident "Yes.")

- "For anodizing, what process do you use and how do you control for color consistency across batches?" (A great answer involves mentioning Type II vs Type III, control over tank parameters, and using a spectrophotometer for color matching.)

- "For powder coating, how do you prepare the surface to ensure maximum adhesion?" (They should mention specific steps like chemical cleaning and sandblasting.)

What Separates a True Engineering Partner from a Simple Machine Shop?

You send out your STEP file for a quote and get a price back in an hour. Is this excellent customer service, or is it a major red flag that no one actually analyzed your design?

A machine shop makes what you send them. An engineering partner reviews your design and provides a Design for Manufacturability (DFM) report, proactively identifying potential issues and suggesting improvements for reliability, cost, or assembly before you even cut metal.

analysis for enclosures"

analysis for enclosures"

The most expensive problems are the ones you discover after you’ve paid for tooling and parts. A DFM review is the single most valuable, risk-reducing step in the entire procurement process. It's the difference between reactive problem-solving and proactive engineering.

The Value of a Second Opinion

You are the expert on your electronics, but a good enclosure partner is an expert on metal. They see hundreds of designs a year and know exactly where designs fail in the real world. A DFM analysis isn't about criticizing your work; it's about applying manufacturing expertise to strengthen it. For example, we might see internal sharp corners in a pressurized housing and recommend adding a small radius to eliminate a stress concentration point that could lead to cracking. Or we might see a design that requires five different machine setups and suggest a small design tweak that allows it to be made in two, saving significant cost on a large run.

A simple machine shop will just machine the sharp corner. When it fails in the field, they’ll say, "We just made the print." An engineering partner helps you prevent that failure from ever happening.

Machine Shop vs. Engineering Partner

| Aspect | Machine Shop | Engineering Partner (Your Goal) |

|---|---|---|

| Response to RFQ | Sends a price quote. | Sends a quote and a DFM analysis or questions. |

| Design Input | "We'll make whatever your file shows." | "Have you considered increasing this radius to improve strength?" |

| Problem Solving | Reactive (fixes mistakes after they happen). | Proactive (identifies risks before production begins). |

| Focus | Making a part at the lowest cost. | Delivering a functional component that meets all system goals. |

| Value | Transactional (price per part). | Collaborative (lowers your total cost of ownership9). |

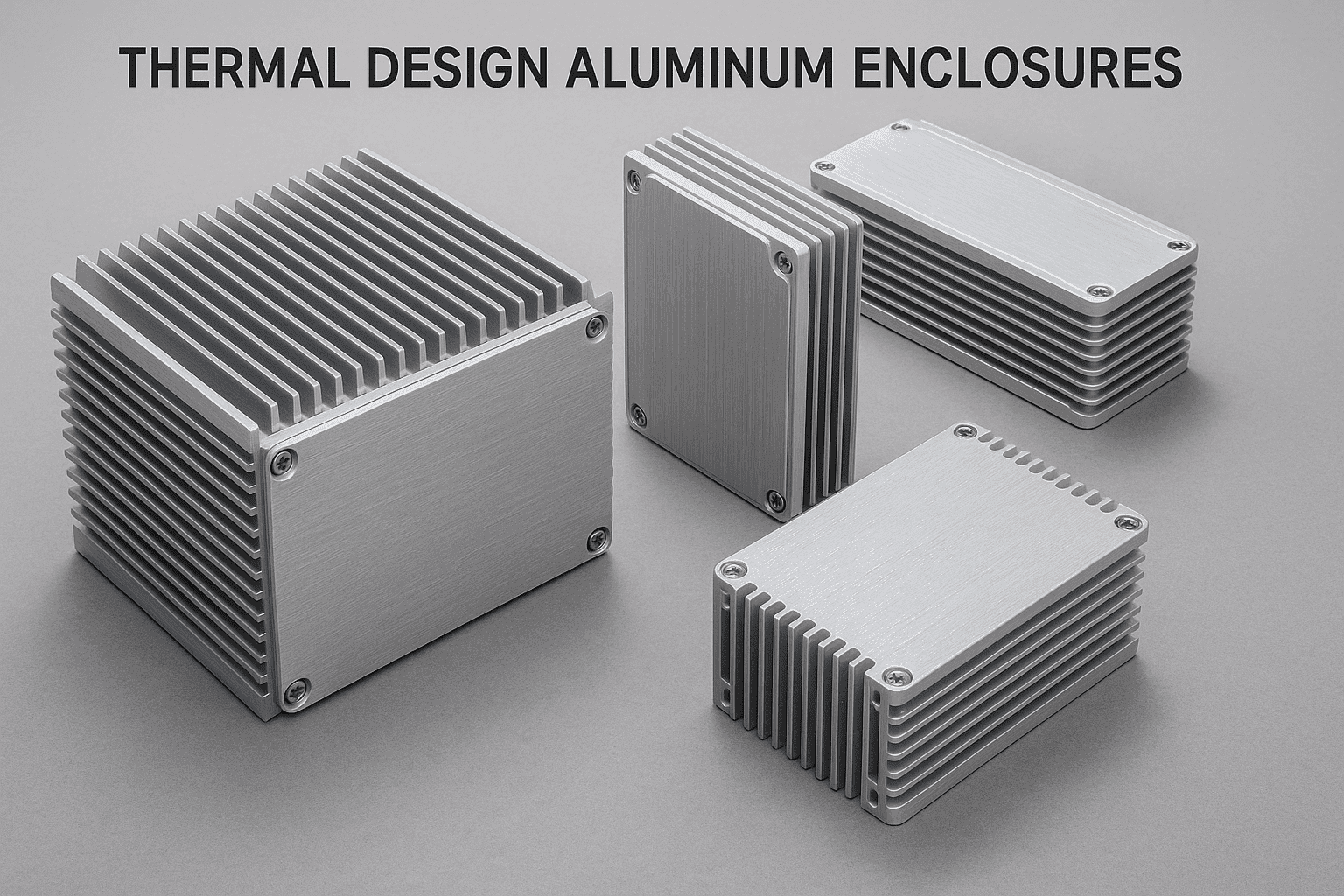

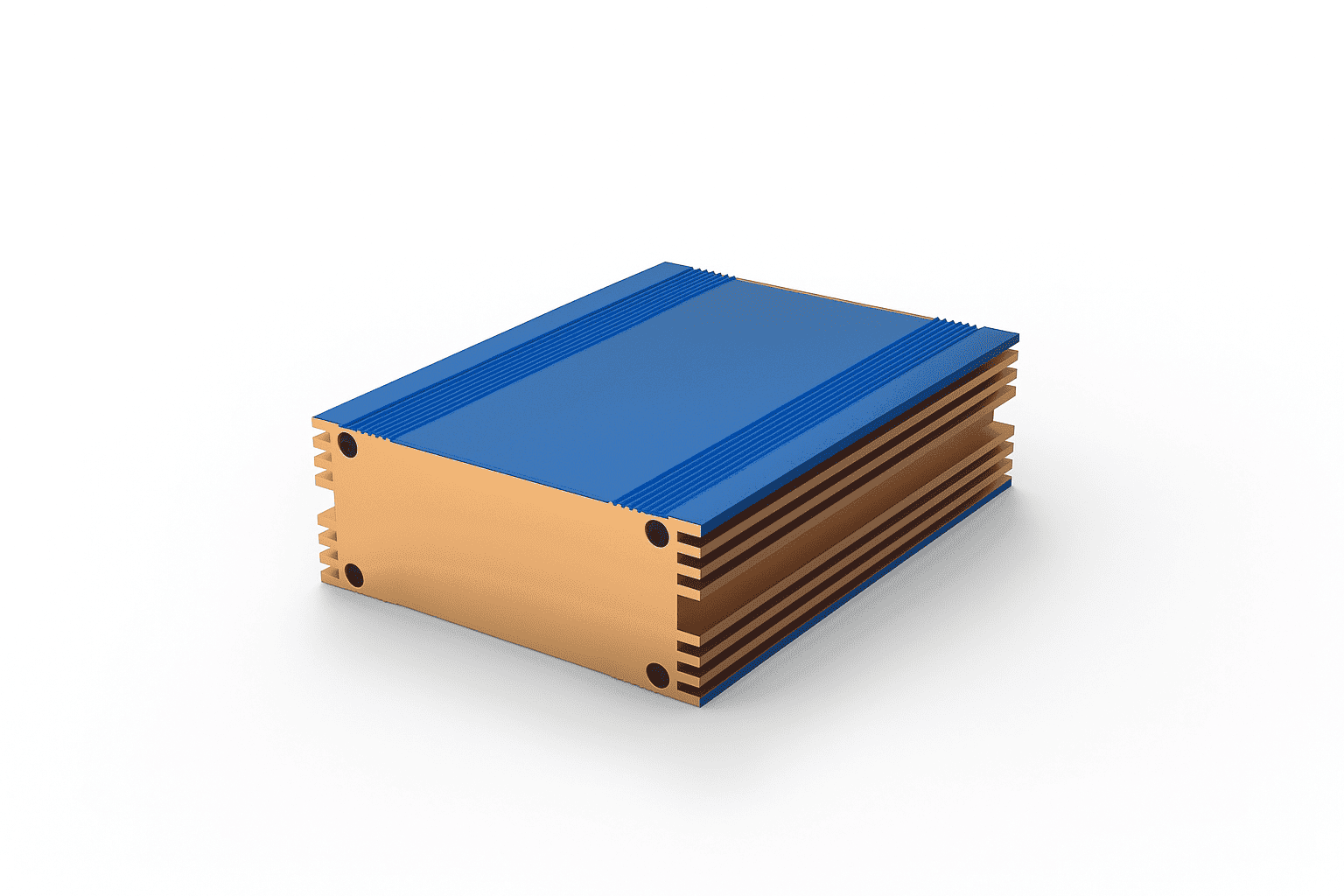

How Can I Tell if They Actually Understand Thermal Management and EMC?

Your enclosure isn't just a box; it's a critical part of your thermal and EMI mitigation strategy. But when you ask a potential supplier if they can handle EMC, they say, "No problem, we use conductive gaskets."

Probe deeper by asking them to describe a specific a project where they helped a client solve a thermal or EMC problem. Don't ask if they can do it; ask them how they've done it. Their answer will reveal if they think in terms of physics or just parts.

"Passive thermal management design"

"Passive thermal management design"

Many suppliers see heatsinks and EMC gaskets as features to add to a parts list. True partners understand them as components in a system. They know that a heatsink is useless without a clear airflow path and that an EMC gasket is ineffective if the mating flange isn't perfectly flat and conductive.

Thinking in Systems, Not Parts

On a vetting call, I try to understand the engineer's core problem. Is it a 150W power amplifier needing passive cooling in a sealed case? Is it a sensitive medical device that must be shielded from RF interference?

A good supplier will ask you questions like:

- "What is the total TDP of the components inside?"

- "What is the maximum allowable ambient temperature inside the enclosure?"

- "Where are your heat-generating components located relative to the desired airflow path?"

- "What shielding effectiveness (in dB) are you trying to achieve at what frequencies?"

If their questions are only about the dimensions of the cutout for a fan, they don’t understand thermal management.

Case Example: Solving an EMI Puzzle

A customer developing an industrial IoT gateway was failing radiated emissions testing. Their previous supplier had enclosed it in a standard aluminum box with a generic conductive foam gasket. The problem was, the large connector panel was acting like a giant antenna. They saw "gasket" as the solution. We saw the problem as "aperture control." We worked with them to redesign the I/O panel, replacing large openings with an array of smaller, shielded connectors and ensuring a solid metal-to-metal connection between the panel and the chassis. This, combined with the right gasket, allowed them to pass certification.

What Questions Uncover Their Real Production and QC Processes?

Your prototype was flawless. You approved it and placed a production order for 500 units. The first shipment arrives, and 15% of the enclosures have misaligned PEM nuts or blemishes in the anodizing.

Ask this simple question: "What specific steps do you take to ensure the 500th unit is identical to the approved prototype?" Their answer must include mentions of a "golden sample10," First Article Inspection (FAI)11 reports, and documented in-process quality checks.

"Golden sample quality control process"

"Golden sample quality control process"

Consistency is the hallmark of a professional manufacturing operation. Anyone can make one perfect part if they spend enough time on it. The real challenge—and the true test of a supplier—is making hundreds or thousands of them perfectly.

Escaping the "Prototype Trap"

Many low-cost shops fall into the "prototype trap." They use their most skilled machinist and their best machine tool to create a "golden" prototype. It looks fantastic. Once you approve it, however, they shift the production run to less-calibrated machines or less-experienced operators to save costs. This is where inconsistencies appear.

A reliable partner uses the exact same production method for the prototype as they do for the full run. The prototype isn't just a model; it's a test of their production process.

The Three Pillars of Production QC:

- The Golden Sample: After you approve the prototype, it should be signed, dated, and kept on the production floor as the undisputed physical benchmark for the entire run. This is used to visually check subjective qualities like color, texture, and finish.

- First Article Inspection (FAI)11 Report: For the first part off the production line, the supplier should conduct a full dimensional inspection against your drawing. They should measure every specified dimension and record the results in an FAI report, which they send to you for approval before continuing the run.

- In-Process & Final QC: Good suppliers don’t just check the last part. They perform checks at critical steps during the manufacturing process (e.g., after machining but before anodizing) to catch deviations early. A final QC report should accompany your shipment.

When you ask about their process, listen for these specific terms. If they give you a vague answer like, "Don't worry, we have good quality," it's a major red flag.

Conclusion

Finding the right partner is an exercise in engineering diligence. In a 20-minute call, you can cut through the marketing fluff and assess the three things that truly matter: engineering depth12, problem-solving ability, and process reliability.

Understanding DFM can help you ensure your designs are optimized for manufacturing, reducing costs and improving reliability. ↩

Material traceability is crucial for quality assurance and compliance; learn how it impacts product reliability. ↩ ↩

Identifying challenges early can save time and costs; learn about solutions to these common issues. ↩

Choosing the right partner can enhance your project; understand the qualities that make a supplier a true partner. ↩

Supply chain verification is vital for quality assurance; learn how it affects your product's reliability. ↩

Anodizing thickness affects durability and performance; explore its significance in manufacturing processes. ↩

Proper adhesion is vital for finish quality; discover methods to ensure effective powder coating. ↩

Vibration testing ensures product durability; learn about its importance in product design and manufacturing. ↩ ↩

Understanding total cost of ownership helps in budgeting; explore its components for better financial planning. ↩

A golden sample is essential for consistency; learn how it helps maintain quality throughout production. ↩

FAI is critical for ensuring production quality; discover its role in maintaining manufacturing standards. ↩ ↩

Engineering depth ensures thorough understanding; learn how it impacts product quality and reliability. ↩