Your enterprise customers are starting to ask about your ESG score. You're getting questions about recycled content1 and carbon footprint2s. Suddenly, sustainability isn't just a buzzword; it's a potential deal-breaker.

A clear sustainability roadmap turns this pressure into a competitive advantage. Focus on creating a closed-loop for aluminium recycling3, calculating your product's carbon footprint, and being prepared for any customer ESG audit4.

"The Three Pillars of a Sustainability Roadmap"

"The Three Pillars of a Sustainability Roadmap"

A few years ago, a large medical device company sent us their supplier questionnaire. Tucked away in the back was a section on Environmental, Social, and Governance (ESG) policies. At the time, we had good practices, but nothing formally documented. It was a scramble to pull together the data on our waste streams and energy use. That was the moment I realized sustainability was moving from the marketing department to the purchasing department. It's no longer a "nice-to-have." For serious industrial customers, it's a requirement. This pushed us to build a formal roadmap, not just for them, but for our own future.

How Can We Move Beyond Simple Recycling to a True Circular Economy?

You collect your aluminum scrap and prototypes, and the recycling company picks it up. You feel good, but you don't know where it actually goes or what it becomes.

This is often "downcycling." A true circular economy means creating a closed loop that preserves the material's high quality, turning your waste directly back into your raw material supply.

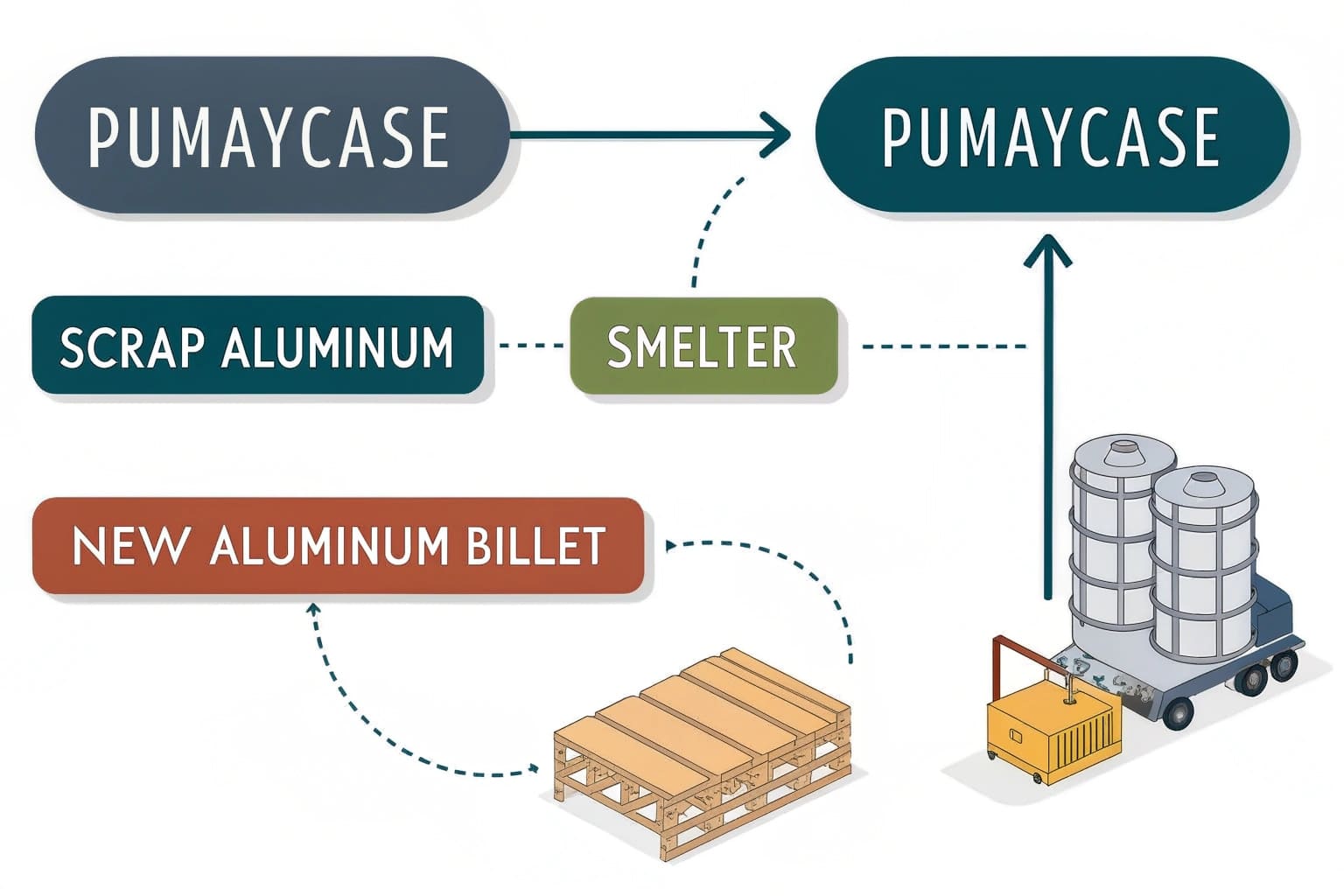

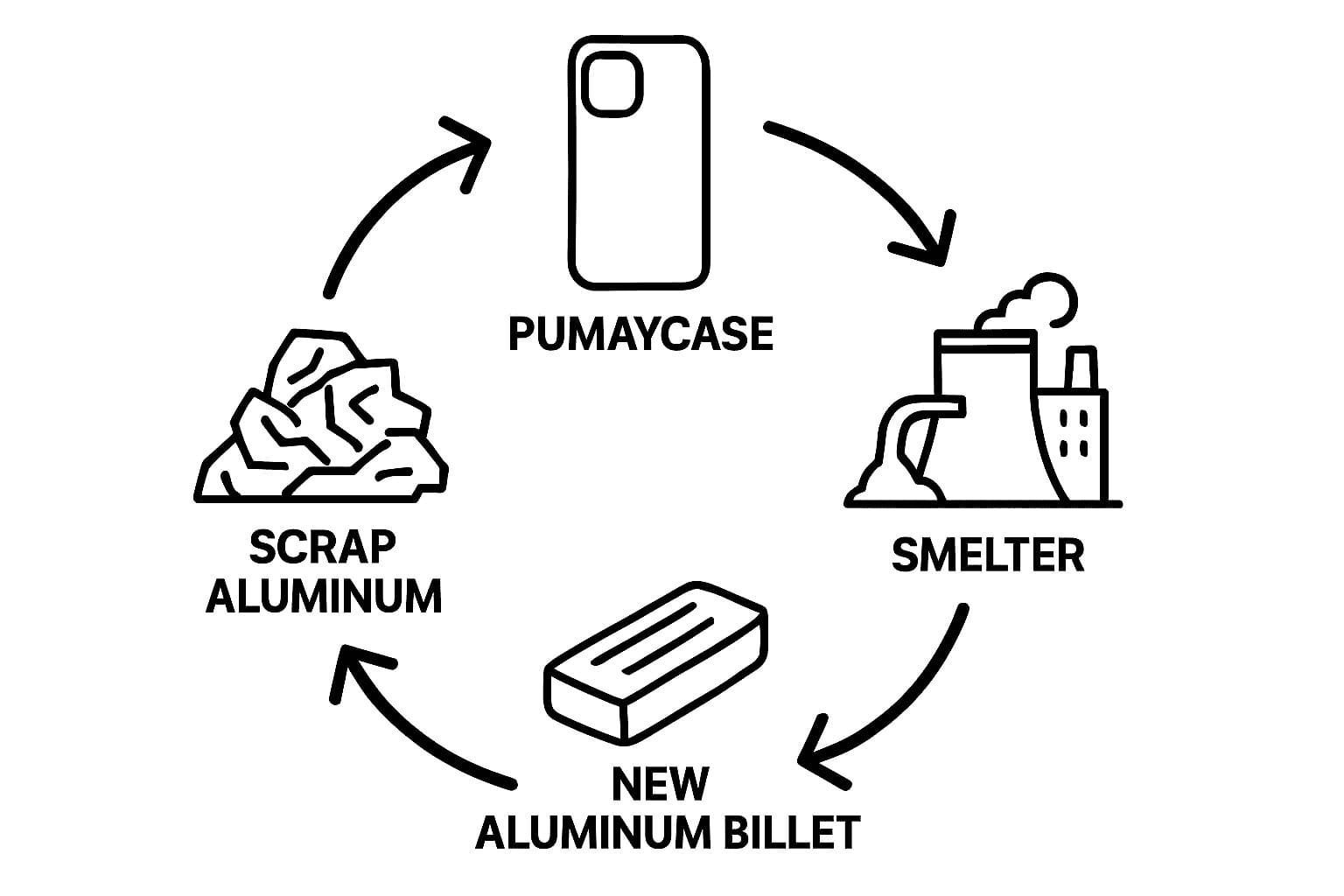

"A Closed-Loop Aluminium Recycling System"

"A Closed-Loop Aluminium Recycling System"

A true circular economy is different from standard municipal recycling. When you toss your high-grade 6063 aluminum scrap into a mixed bin, it gets melted down with lower-grade materials like old window frames or beverage cans. The resulting alloy loses its specific mechanical properties and can only be used for less demanding applications. This is "open-loop" recycling. A "closed-loop" system is our goal. We segregate all of our 6063 scrap in dedicated, clearly labeled bins. We then work directly with an aluminum extruder who can remelt this pure scrap and use it to create new 6063 billets. This process uses about 95% less energy than making aluminum from raw bauxite ore and ensures the material's integrity is maintained. It's the most impactful step you can take toward real sustainability.

Open-Loop vs. Closed-Loop Recycling

| Feature | Open-Loop (Standard Recycling) | Closed-Loop (Circular Economy) |

|---|---|---|

| Material Quality | Degraded, mixed with other alloys. | Preserved, remains high-grade. |

| End Product | Lower-value items (e.g., castings). | High-value items (e.g., new extrusions). |

| Energy Savings | Good (but less efficient). | Excellent (~95% savings). |

| Traceability | Lost. | Maintained. |

How Do You Actually Calculate Your Product's Carbon Footprint?

A customer asks for the CO₂ footprint of your enclosure. You want to give them an answer, but the calculation seems incredibly complex, and you don't know where to begin.

You don't need a Ph.D. in climate science. You can estimate your carbon footprint by focusing on three main areas: the material, the manufacturing energy, and the shipping logistics.

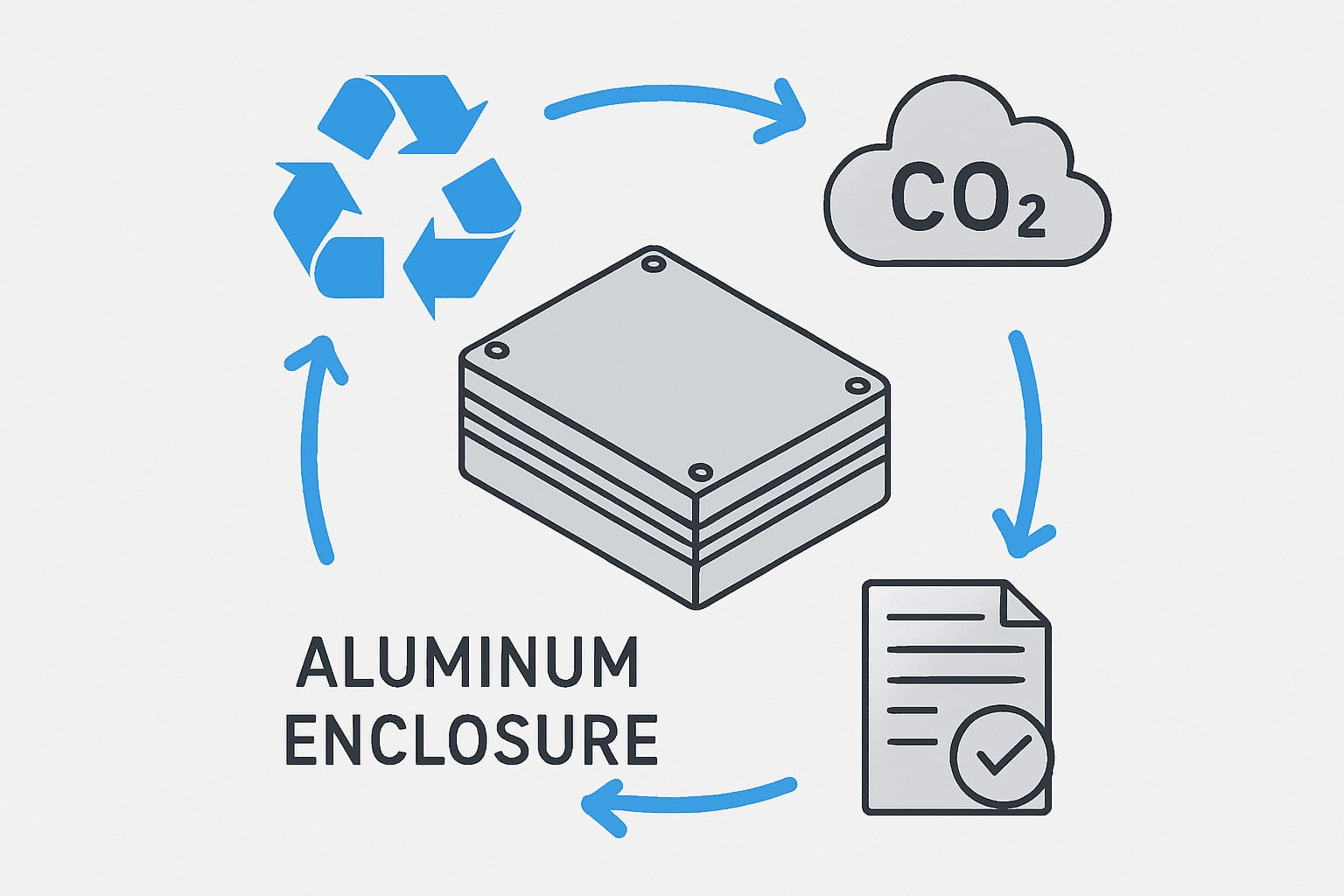

"Calculating a Product's Carbon Footprint"

"Calculating a Product's Carbon Footprint"

Calculating a product's carbon footprint means estimating the total greenhouse gas emissions, measured in kilograms of CO₂ equivalent (kg CO₂e), for one unit. We break it down into manageable parts. First is the material itself. This is the biggest factor. Virgin aluminum made from bauxite ore has a massive footprint (around 15-20 kg CO₂e per kg). High-recycled-content aluminum can be as low as 2-3 kg CO₂e per kg. Second is manufacturing. We look at the electricity consumed by our CNC machines, anodizing lines, and other equipment, and multiply it by the carbon intensity of our local energy grid. Third is logistics: the emissions from shipping the raw material to us and the finished product to the customer. By adding these three parts together, we get a solid, defensible estimate to share with our clients.

Sample Carbon Footprint Breakdown (Per Unit)

| Stage | Emission Source | Example Value (kg CO₂e) |

|---|---|---|

| Material | 1 kg of high-recycled aluminum. | 2.5 kg |

| Manufacturing | CNC machining, anodizing, assembly. | 0.8 kg |

| Logistics | Inbound & outbound shipping. | 0.4 kg |

| Total | Total Estimated Footprint | 3.7 kg |

What Do Customers Actually Want to See in an ESG Audit?

You get an email with the subject "Supplier ESG Audit." It sounds formal and intimidating, and you're worried you don't have the right policies or paperwork to satisfy a big corporate client.

Don't panic. An ESG audit is primarily a request for documentation. Customers want to see proof that your sustainable practices are real, consistent, and well-managed.

"Passing an ESG Audit with Confidence"

"Passing an ESG Audit with Confidence"

When a customer performs an ESG audit, they are doing their own due diligence. They need to prove to their stakeholders that their supply chain is responsible. For a company like ours, the focus is usually on the "E" – Environmental. They want to see the evidence behind our claims. This means having documents ready. We have traceability5 certificates for our aluminum that state the percentage of recycled content. We have our electricity bills and calculations for our manufacturing footprint. We have a documented policy for our closed-loop recycling program. We also have our ISO 9001 quality certification, which, while not an environmental standard, shows we have robust processes. Being able to produce these documents quickly and professionally shows we are a serious, reliable partner and turns a dreaded audit into a moment to shine.

Key Documents for an Environmental Audit

| Area | Document/Proof Needed | Why It Matters to the Customer |

|---|---|---|

| Material Sourcing | Material Traceability Certificates. | Proves your recycled content1 claims are real. |

| Energy Consumption | Utility bills, consumption calculations. | Shows you are measuring and managing your footprint. |

| Waste Management | Written policy, waste handler contracts. | Demonstrates a commitment to a circular economy. |

| Compliance | ISO Certifications (e.g., 9001, 14001). | Shows you operate under a formal, audited system. |

Conclusion

A sustainability roadmap is no longer optional. A circular economy for aluminium recycling, a clear carbon footprint calculation, and readiness for an ESG audit build the trust required to win tomorrow's business.

Understand the significance of recycled content in products and its impact on sustainability. ↩ ↩

Learn effective methods to calculate and reduce your product's carbon footprint for better sustainability. ↩

Explore how aluminium recycling contributes to sustainability and reduces environmental impact. ↩

Understand the key components of an ESG audit and how to prepare for it to meet customer expectations. ↩

Learn about the importance of traceability in ensuring sustainable recycling practices. ↩