Customization services are not just about meeting specific needs—they also provide a strategic advantage by optimizing production and lowering overall costs. Many businesses reduce expenses significantly through tailored solutions that improve efficiency and performance.

Custom aluminum enclosures1 help customers cut costs by minimizing waste2, reducing production time3, and ensuring longer product lifespan.

Let’s break down how customization saves money for customers.

How Does Customization Reduce Production and Material Costs?

Standard solutions often lead to unnecessary expenses due to over-specification or poor fit. Custom enclosures address this problem by offering exactly what is needed—nothing more, nothing less.

This precision reduces material waste and eliminates the cost of unnecessary features.

Key Cost-Saving Factors

| Customization Factor | Cost-Saving Benefit |

|---|---|

| Material Optimization | Reduces waste by using only necessary materials |

| Streamlined Production | Shortens production cycles with efficient designs |

| Right-Sized Components | Avoids paying for oversized or underperforming enclosures |

By delivering enclosures that match exact specifications, customers avoid expensive modifications and reduce overall production costs.

How Does Custom Design Increase Operational Efficiency?

Custom aluminum enclosures are tailored to enhance performance and functionality, which improves operational efficiency for customers.

Better thermal management4, easier installation, and modular designs reduce downtime and maintenance costs.

Operational Benefits of Custom Enclosures

- Efficient Heat Dissipation: Prevents overheating, reducing repair costs and extending equipment lifespan.

- Quick Installation5: Custom dimensions and pre-configured mounting options save time and labor expenses.

- Modular Configurations6: Enable easy upgrades and reduce the need for full system replacements.

For example, in industrial automation, a custom enclosure with pre-installed cable management systems can significantly reduce installation time and labor costs.

How Do Custom Solutions Improve Product Longevity?

Customized aluminum enclosures are built for specific environments and use cases, which improves durability and longevity.

Longer-lasting products reduce the need for frequent replacements, resulting in significant cost savings over time.

Key Features That Extend Product Life:

- Corrosion-resistant finishes for harsh environments

- Enhanced sealing to prevent water and dust ingress

- Tailored heat management solutions for high-performance electronics

Investing in a custom enclosure that meets exact operating conditions can save customers from costly equipment failures and downtime.

How Can Customization Reduce Logistics and Storage Costs?

Custom enclosures are often designed to be more compact, lightweight, or modular compared to standard solutions. This can reduce shipping and storage costs.

Optimized designs lead to lower transportation fees and less warehouse space required.

For instance:

Lightweight materials reduce shipping weight, lowering transportation costs.

Compact designs optimize space, reducing storage requirements and inventory costs.

- -

The End

Customization services help customers reduce costs by optimizing materials, increasing efficiency, and extending product life. Tailored solutions minimize waste, reduce production time, and prevent unnecessary expenses, offering long-term savings and greater value.

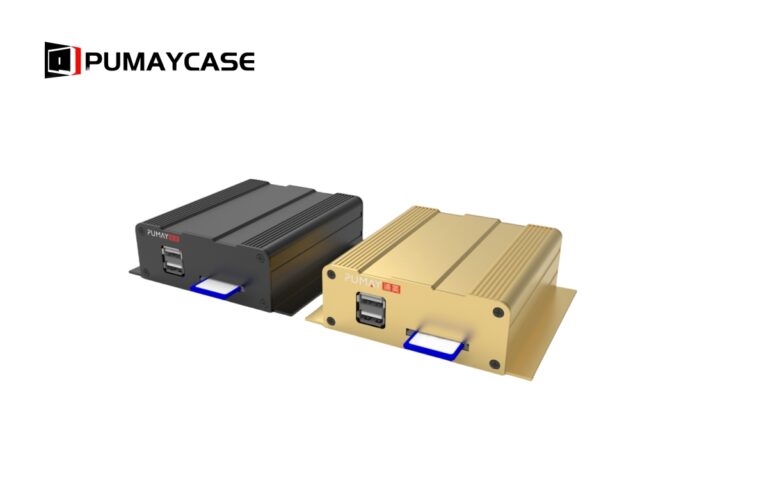

Explore how custom aluminum enclosures can enhance efficiency and reduce costs for your business. ↩

Learn about the importance of waste reduction in cost-saving strategies for businesses. ↩

Discover proven strategies to streamline production processes and save time and money. ↩

Explore how better thermal management can enhance equipment lifespan and reduce costs in your operations. ↩

Learn about the advantages of quick installation and how it can save time and reduce labor expenses. ↩

Discover how modular configurations can facilitate upgrades and minimize system replacement needs. ↩