Sourcing from China feels risky. You worry about scams, poor quality, and communication breakdowns that can derail your project and budget. This uncertainty is stressful and time-consuming.

Verify a manufacturer by checking their business license[^1] for "manufacturing" scope, requesting a real-time factory video tour[^2], and assessing their engineering team's responsiveness. Ordering a custom prototype[^3] is the ultimate test of their actual capabilities.

“Verifying a 19-inch enclosure manufacturer in China”

“Verifying a 19-inch enclosure manufacturer in China”

Finding a trustworthy partner overseas is one of the biggest challenges for product engineers and startups. The distance and language barrier can make it feel like a gamble. But with the right checklist, you can systematically remove that risk and find a partner who will help your project succeed, not hold it back.

How can you tell a real factory from a trading company[^4]?

Their website claims they are a factory, but you're not sure. You could be paying extra to a middleman who has zero control over production quality or lead time[^5]s.

Ask for their business license[^1]; a true manufacturer's "business scope" will include words like "manufacturing" or "production." Also, request a live video call to tour their workshop. A trading company[^4] can't do this.

“Factory vs. trading company[^4] verification”

“Factory vs. trading company[^4] verification”

Looking Behind the Website

This is the first and most important check. Many online storefronts are just trading companies that outsource your order to the lowest bidder. This creates huge risks for an engineer like Jeff, who needs tight control over tolerances. When you use a trading company[^4], you're inviting problems like tolerance mismatch from multi-vendor sourcing. I started PUMAYCASE after years of working in an actual aluminum profile factory, and I built our business on the principle of direct control. A true manufacturer will be proud to show you their operations. Ask for a live video call and say you want to see the CNC machines running. A trading company[^4] will make excuses. At PUMAYCASE, we welcome these tours because our 4,500 m² integrated manufacturing line is our biggest strength.

Here is a quick way to spot the difference:

| Attribute | True Manufacturer (like PUMAYCASE) | Trading Company |

|---|---|---|

| Business License | Scope includes "manufacturing," "production" | Scope includes "wholesale," "export," "trade" |

| Facility Tour | Can provide a live video tour of their workshop | Cannot, or will show a partner's workshop |

| Technical Depth | Engineers can offer DFM feedback[^6] | Salespeople forward questions and answers |

| Lead Time | Shorter and more reliable | Longer and less reliable due to outsourcing |

What's the best way to assess quality from overseas?

Website photos look great, but you can't physically touch the product. Committing to a large order based on pictures alone is a huge gamble that could result in receiving junk.

The most reliable method is ordering a custom prototype[^3] made from your own design files. This lets you physically test the material quality, finish durability, and dimensional accuracy before committing to a larger production run.

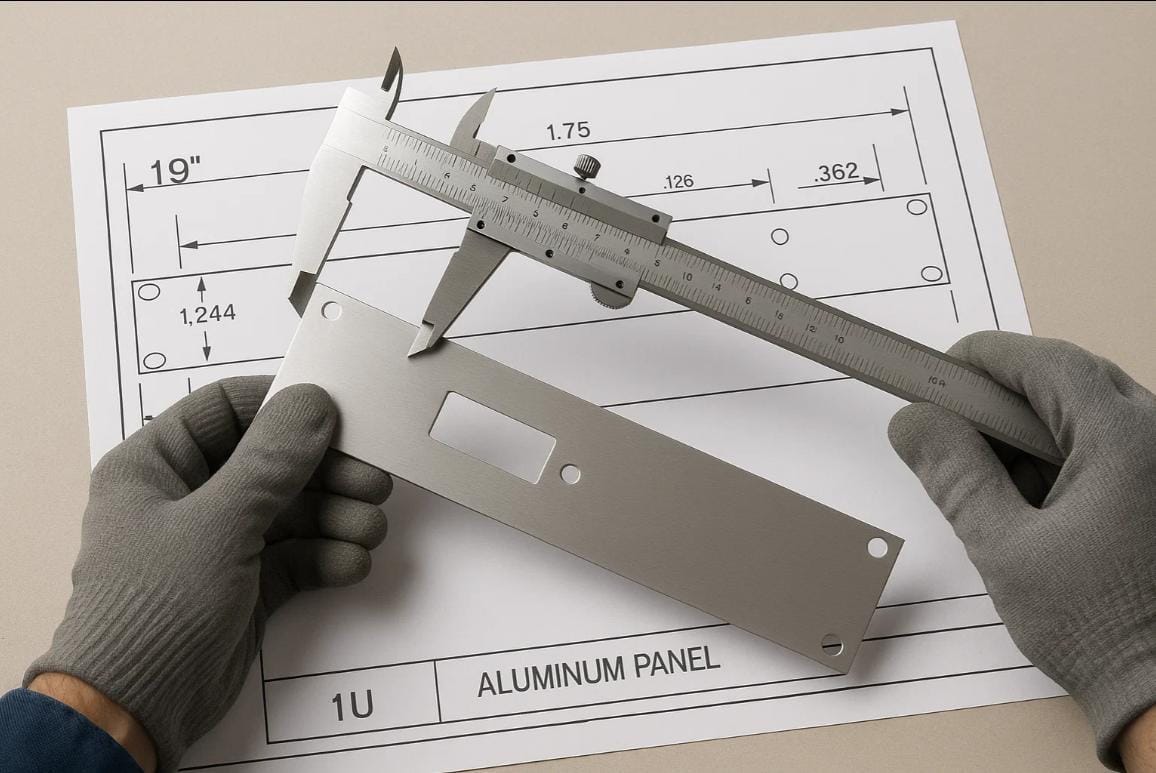

“Assessing enclosure quality with a prototype sample”

“Assessing enclosure quality with a prototype sample”

The Ultimate Physical Test

A custom prototype[^3] is your insurance policy against poor quality. It's the only way to be 100% sure that what you designed is what you will get. A standard, off-the-shelf sample is useful, but a prototype made to your exact specifications tells you everything you need to know about a manufacturer's true capabilities. When you receive the sample, you should check three key things. First, feel the material. Does it feel solid, or is it thin and flimsy? Second, test the finish. Try to scratch the anodizing in an inconspicuous area. A quality finish will be tough and resistant. Third, and most importantly, perform a test fit. Do your PCBs mount perfectly? Do your connectors align with the cutouts without any stress? This single step validates their CNC precision[^7]. Also, ask the supplier if they have any quality certifications[^8] like ISO 9001[^9] or test reports for things like IP ratings. We provide IP67/IP68 validation reports to clients to save them the time and expense of in-house testing.

How do you test their technical communication[^10] and support?

You're worried about language barriers and slow replies. A simple technical question gets misunderstood, leading to incorrect parts and weeks of delay. It's a huge source of stress.

Send them your CAD file and ask a specific technical question, like requesting DFM feedback[^6]. A capable supplier will have engineers respond within 24-48 hours with intelligent suggestions, not just a simple "yes, we can do it."

“Testing a supplier's technical communication[^10]”

“Testing a supplier's technical communication[^10]”

Separating the Experts from the Order-Takers

Transparent technical communication[^10] is non-negotiable. This is where a great partner truly shines. An order-taker will just give you a price. A true manufacturing partner will engage with your design. The best way to test this is to send them your 3D files and ask a question like, "Can you review my design for manufacturability and suggest any improvements?" The response you get is incredibly revealing. A great supplier, like PUMAYCASE, will have their engineers provide feedback within 24 hours. They will offer concrete suggestions that can save you money or improve your product's reliability.

Look for these signs in their communication:

Green Flags (A Good Partner)

- They provide a detailed DFM (Design for Manufacturability) report.

- They suggest minor changes to improve strength or lower cost (e.g., "This wall is too thin; we recommend increasing it by 1mm.").

- They ask smart, clarifying questions about your design's function.

- Response time is fast and professional.

Red Flags (A Risky Supplier)

- They only respond with a price.

- They ignore your technical questions.

- They say "no problem" to everything without any analysis.

- It takes them many days to respond to a simple question.

Conclusion

Verify a Chinese manufacturer by checking their business license[^1], ordering a custom prototype[^3], and testing their engineering support[^11]. This simple checklist ensures you find a reliable partner for your project.

---

[^1]: Understanding the significance of a business license can help you avoid scams and ensure quality.

[^2]: A live video tour provides transparency and assurance about the manufacturer's capabilities.

[^3]: A custom prototype allows you to test quality and specifications before large orders.

[^4]: Identifying the risks associated with trading companies can help you make informed sourcing decisions.

[^5]: Understanding lead time helps in planning and managing project timelines effectively.

[^6]: DFM feedback can enhance product design and reduce production costs, ensuring better outcomes.

[^7]: CNC precision ensures that parts are made to exact specifications, reducing errors.

[^8]: Quality certifications provide assurance of a manufacturer's adherence to industry standards.

[^9]: ISO 9001 certification indicates a commitment to quality management and reliability.

[^10]: Effective technical communication is crucial for successful collaboration and project execution.

[^11]: Strong engineering support can lead to better product outcomes and smoother communication.