- Off-the-shelf products ship within 24 hours. Custom samples ship in 8-10 days.

- No MOQ required.

- in stock, ready to ship

- Manufacturer of electronics enclosures

- (86)15813615026

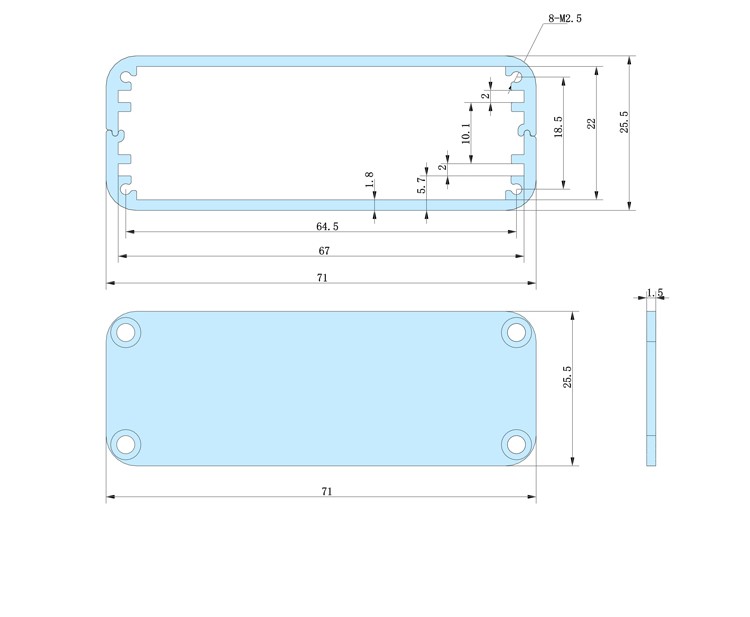

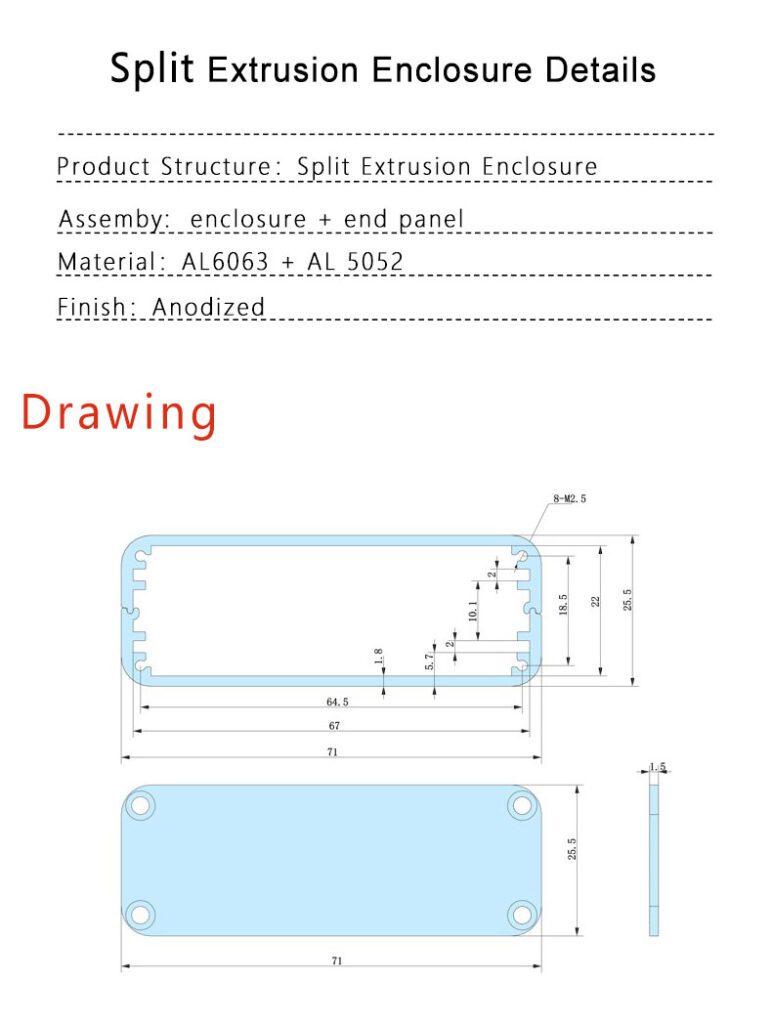

| Item | Size | Mat | Thk | Qty |

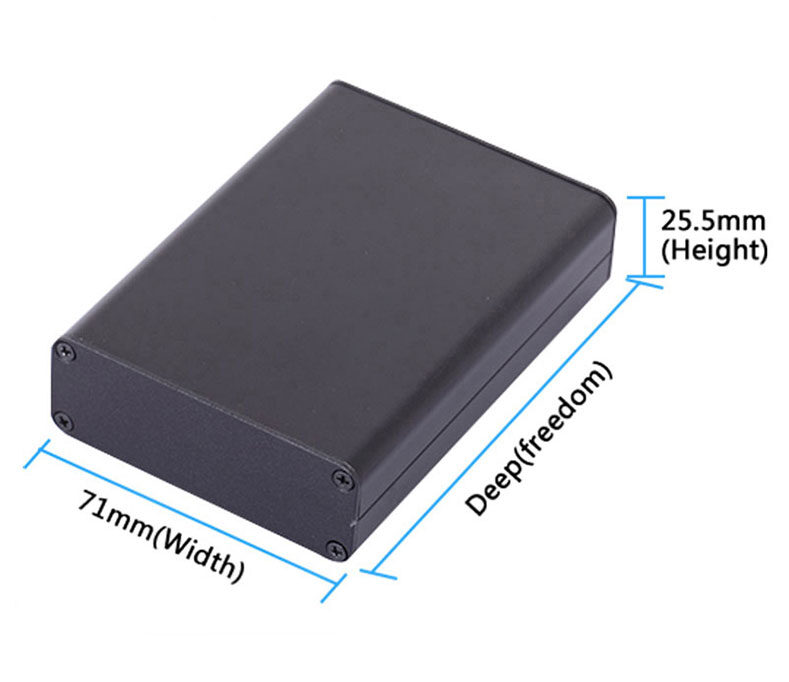

| Box | 71*25.5 | 6063AL | 1.8 | 2 |

| End Panel | 71*25.5 | 5052AL | 1.5 | 2 |

| Screw | M2.5 | iron | 6 | 8 |

3 month workmanship warranty; defects repaired or replaced at Pumaycase's cost, including freight.

100 % sample cost refunded on first batch ≥500 sets.

For forecast agreement ≥3,000 sets, price locked for 3 months; repeat orders ship in 15–18 working days.

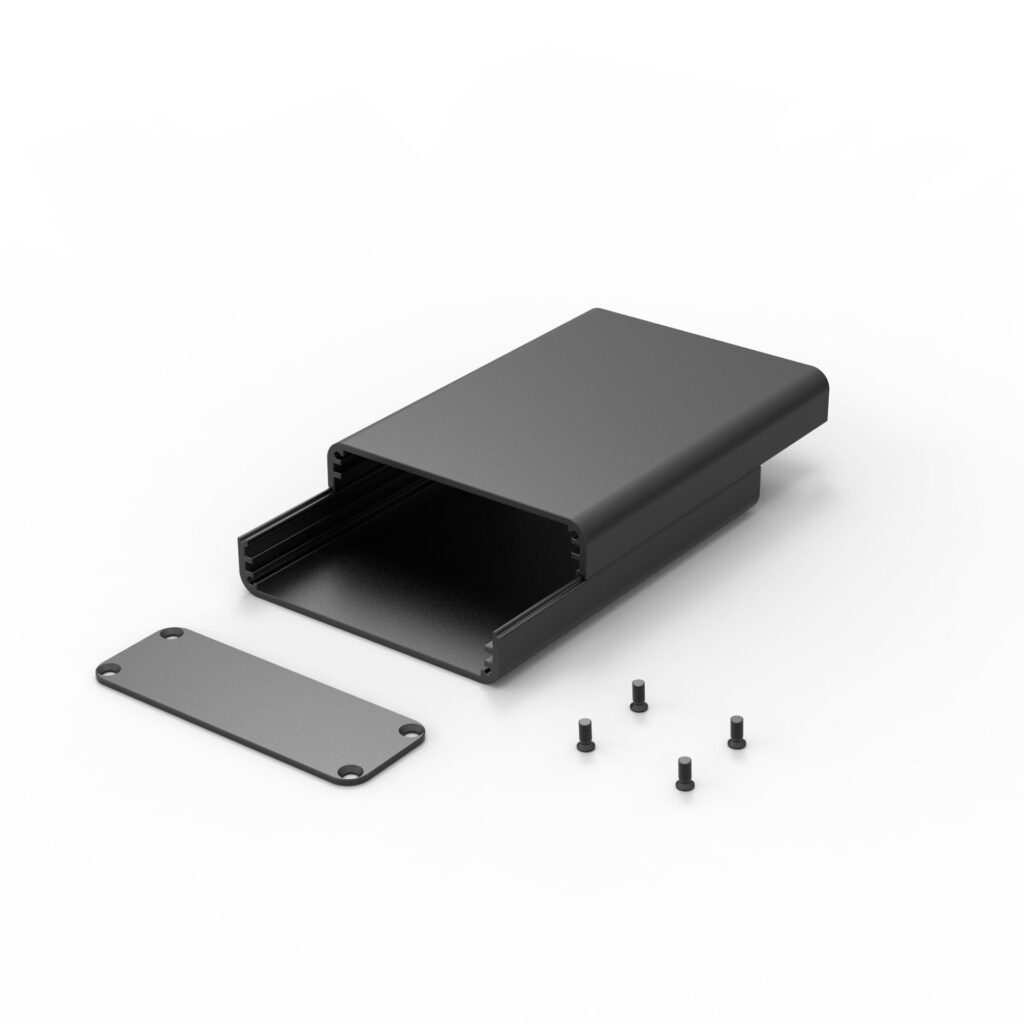

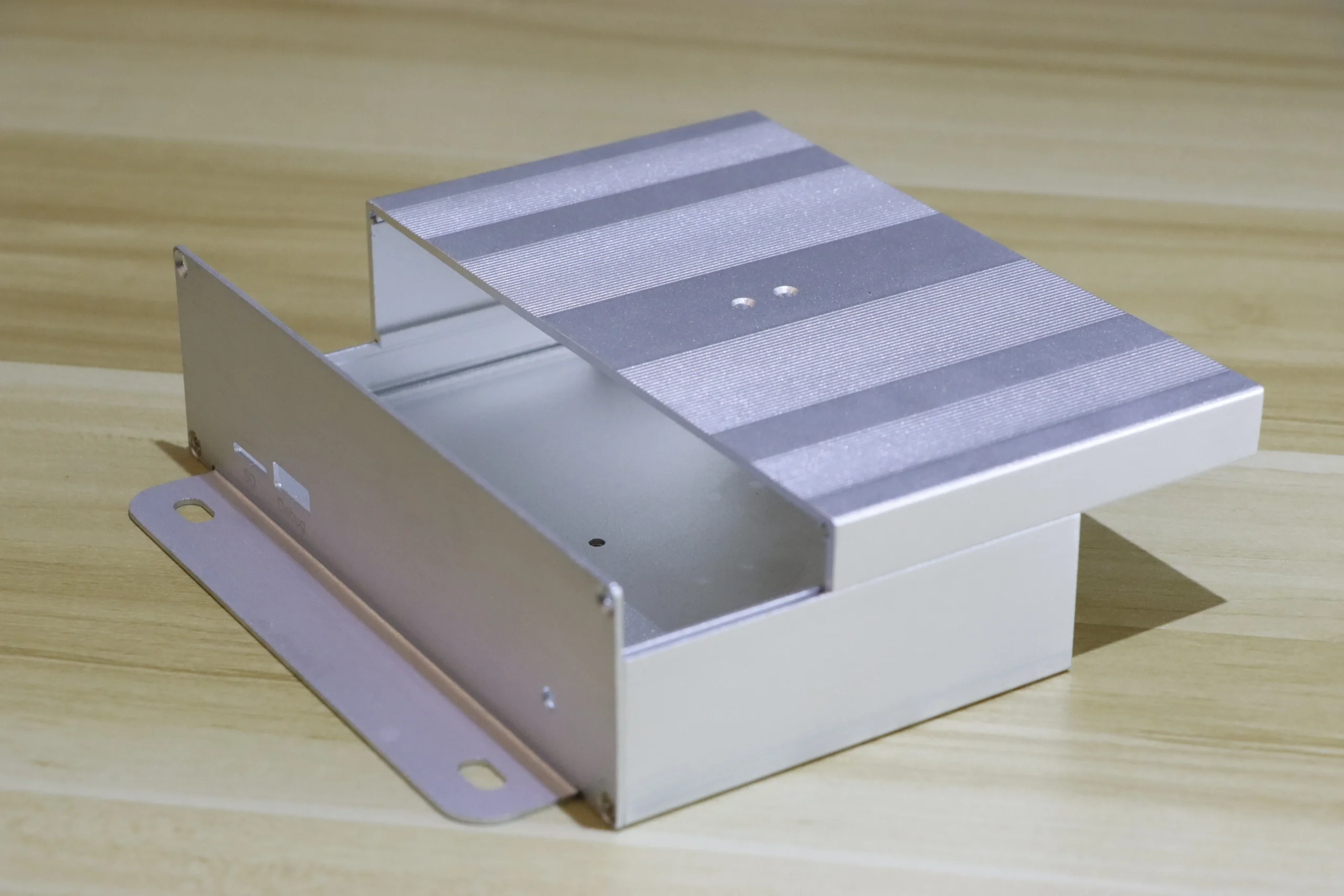

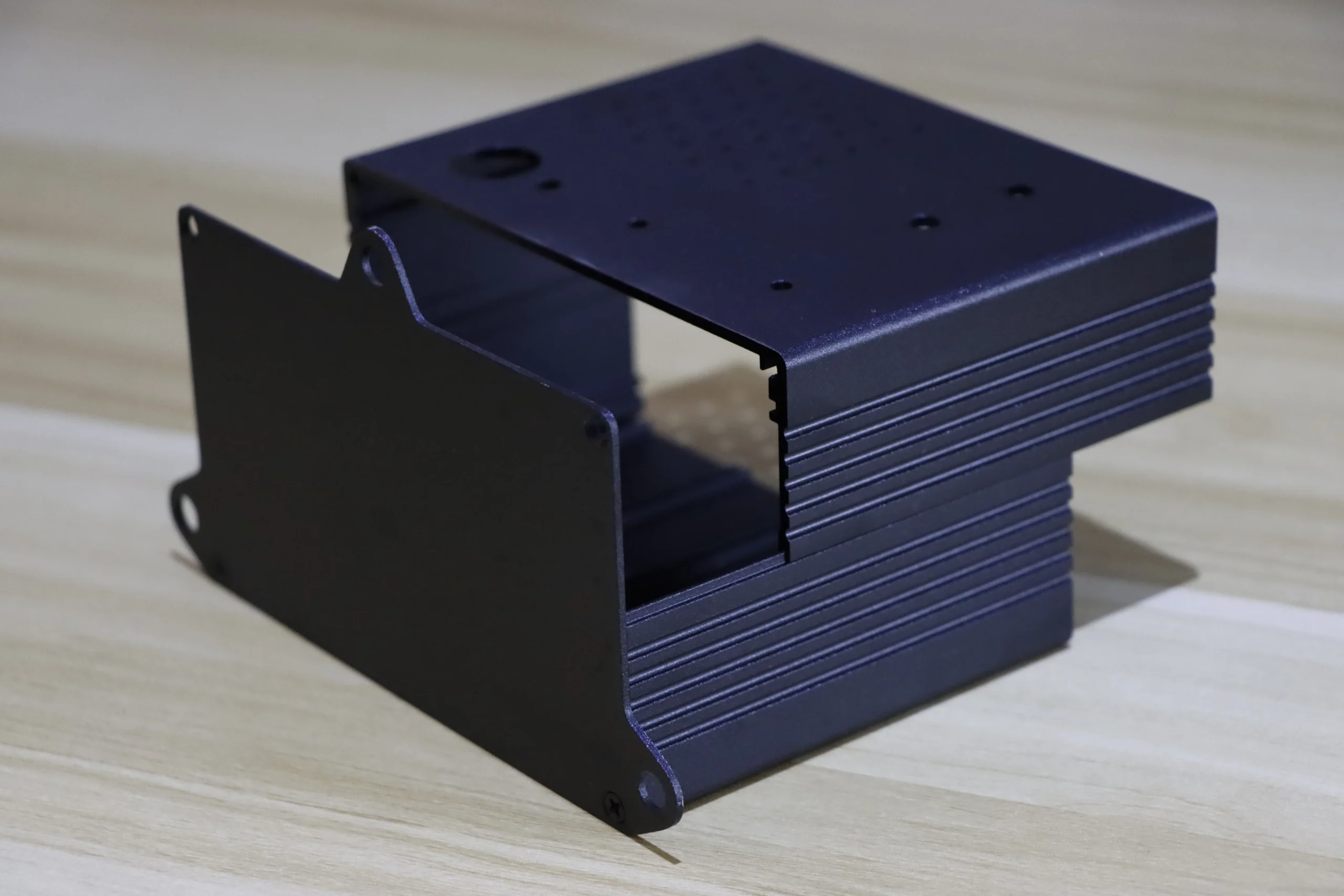

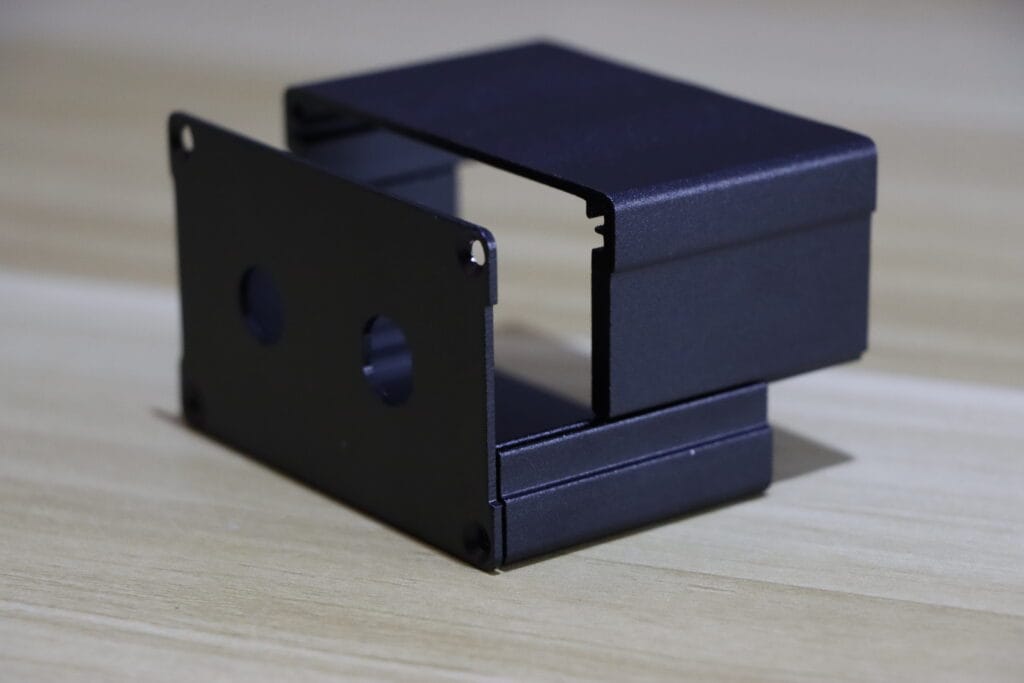

Standard kit includes body + end plates + screws.

Optional M3 clinch studs, brass standoffs, and nylon washers can be supplied; MOQ 100 sets.

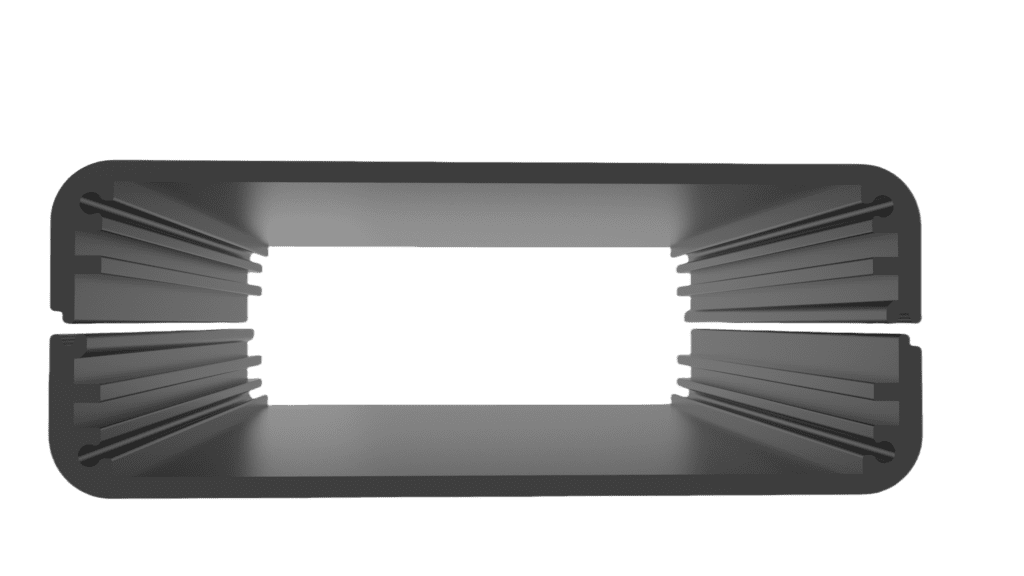

Our electronic enclosures are expertly designed to provide robust protection for industrial electronic devices, ensuring optimal performance in various environments. Crafted from high-quality aluminum, these enclosures offer durability, excellent heat dissipation, and lightweight construction.

Click to Chat

I am online now

Hello. This is Jessie from Pumaycase, How can I assist you today?

WhatsApp Us

🟢 Online | Privacy policy