Facing the maze of product certification can feel like a last-minute roadblock. You’ve perfected the electronics, but now you’re decoding compliance standards. Let me give you a practical engineering roadmap.

Your aluminum enclosure itself does not need a standalone UL or CE mark. Instead, it’s a critical component that enables your final, assembled product to achieve certification. The focus is on how the enclosure’s design contributes to system-level safety, EMC performance, and environmental protection.

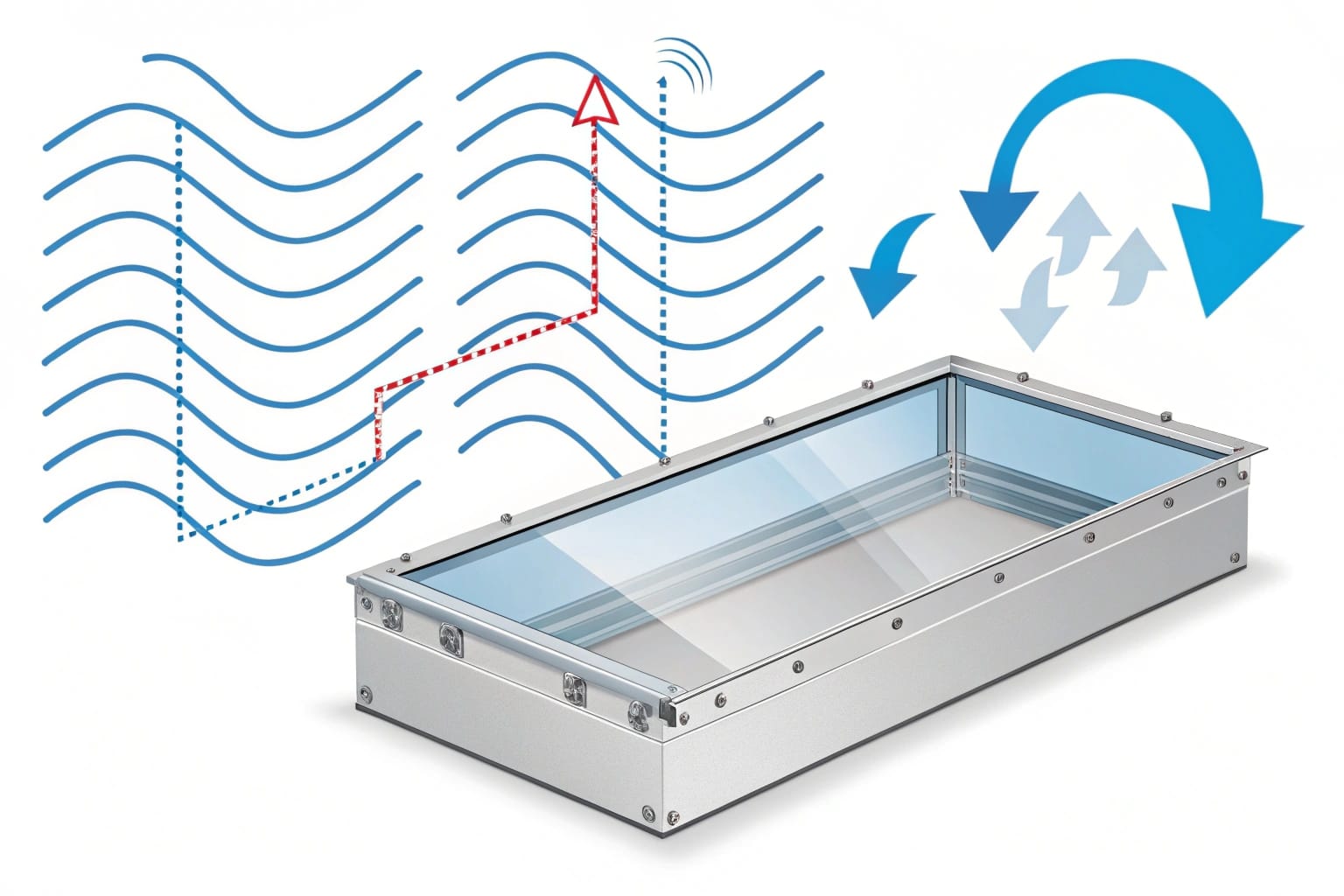

"thermal control design"

"thermal control design"

This distinction is crucial. It shifts your focus from "buying a certified box" to "designing a compliant system." Let's break down what this means for both CE and UL requirements.

What is my enclosure's role in CE marking?

You've been asked for a "CE-certified enclosure1" to sell into the European market. This common request creates confusion and stalls projects because it's based on a fundamental misunderstanding of the process.

The enclosure does not get its own CE mark. It is a key piece of documented evidence in your product's Technical File2 that proves compliance with relevant EU Directives. Its design features—like sealing, shielding, and material choice—are what matter to the assessor.

"EMC shielding guide"

"EMC shielding guide"

The CE mark is a manufacturer's self-declaration. You are certifying that your entire product (your electronics inside our enclosure) meets all applicable EU regulations for safety, health, and environmental protection. The enclosure is a passive component; it has no function on its own. It's the "armor" that helps your system pass the tests.

The Misconception: "Just Buy a CE-Certified Box"

Many engineers believe they can simply source an enclosure with a CE sticker and their compliance work is done. This is incorrect. The CE mark on a finished product, like a power supply, asserts that the entire assembly has been evaluated. Since an empty box has no electronics and performs no function, it cannot be independently assessed against directives like the EMC or Low Voltage Directive (LVD)3. Your responsibility is to select or design an enclosure that provides the physical properties needed to meet those directives once your components are installed.

Case Study: Passing EMC for an Industrial Controller

A client developing an industrial automation controller for the German market came to us after their initial design, housed in a plastic case, repeatedly failed EMC testing for radiated emissions. The switching components on their PCB were generating too much electromagnetic noise, interfering with other equipment.

Their problem wasn't their electronics, but their shielding. We designed a custom extruded aluminum enclosure with two key features: interlocking seams that created a continuous conductive path and a beryllium copper (BeCu) gasket inside the front panel lip. This effectively formed a Faraday cage around their PCB. The result? Their final product passed the EMC Directive4 requirements on the next attempt. We didn’t provide a "CE enclosure"; we provided an EMC-compliant enclosure that enabled their product to earn its CE mark.

Enclosure Design Checklist for CE Marking

When preparing your Technical File2, your enclosure provides physical evidence of compliance. Here’s how its features map to key directives:

| Directive | Enclosure's Contribution | Key Design Feature Example |

|---|---|---|

| EMC Directive | Provides electromagnetic shielding to limit emissions and immunity. | Interlocking panels, conductive gaskets, minimal apertures, RF-tight seams. |

| Low Voltage Directive (LVD) | Protects users from electric shock and ensures electrical safety. | Secure grounding points (studs or threaded holes), proper material thickness, robust construction. |

| RoHS Directive5 | Restricts the use of specific hazardous materials. | Use of compliant materials (e.g., RoHS-compliant aluminum alloys, fasteners, and finishes like anodizing or powder coating). |

| ATEX Directive6 | Prevents ignition in potentially explosive atmospheres (if applicable). | Flameproof joints with precise tolerances, robust construction to withstand internal pressure events. |

How does UL certification apply to aluminum enclosures?

Targeting the North American market? You've likely encountered requests for a "UL Listed7" enclosure. This process is different from CE, but the core principle of system-level responsibility remains.

Unlike CE, an empty enclosure can be independently "UL Listed" under a standard like UL 50E. This certifies its construction and ability to protect against environmental hazards (dust, water), granting it a NEMA/UL Type rating8. However, any modifications you make will void that listing.

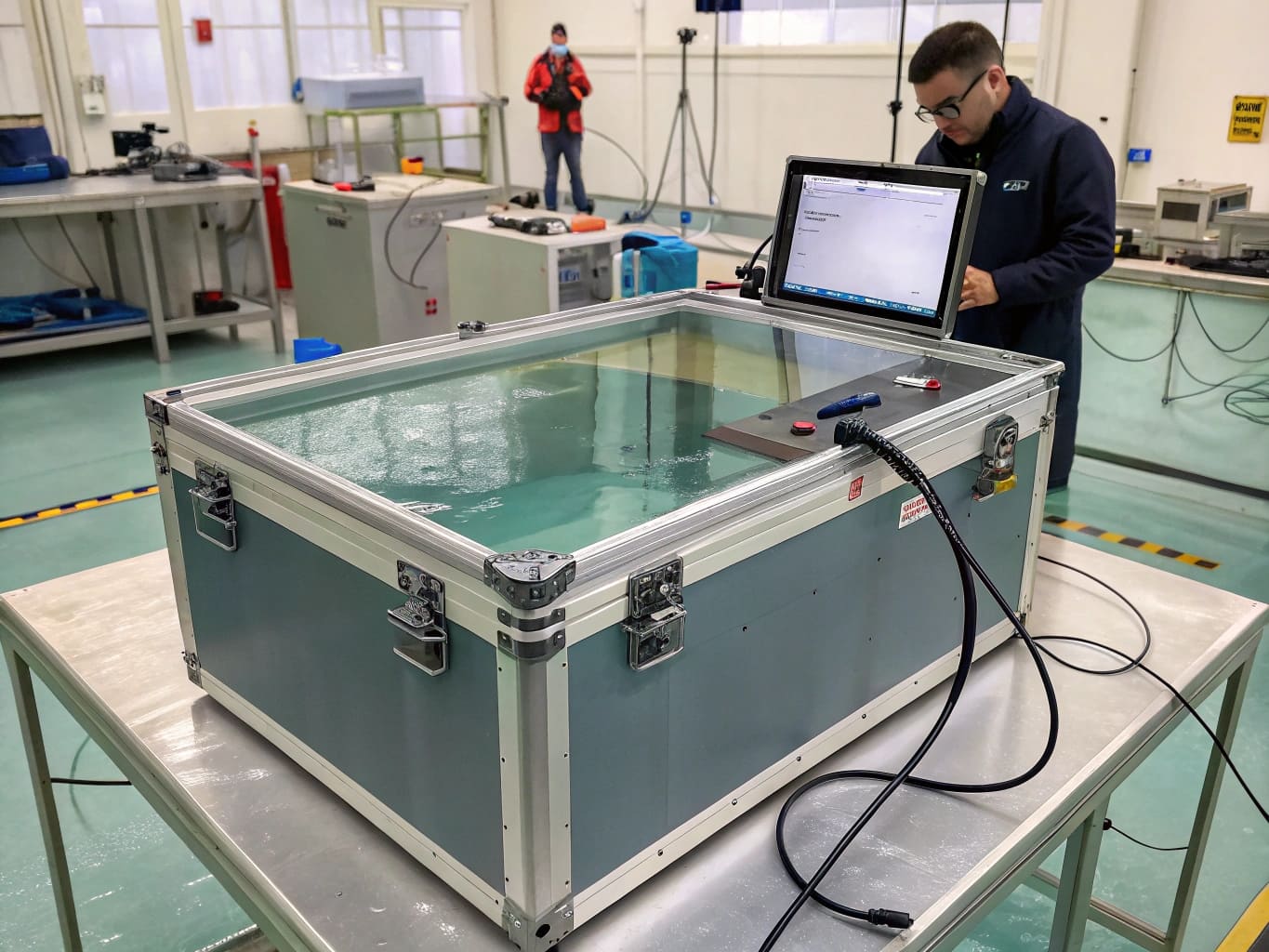

"IP67 case design"

"IP67 case design"

UL is a third-party organization that tests and certifies products for safety. For enclosures, there's a key distinction:

- UL Listed: Applies to standalone products (like our empty enclosures under UL 50E) or end-use systems (like an industrial control panel under UL 508A).

- UL Recognized: Applies to components that are part of a larger UL Listed system (e.g., a specific power supply or switch).

While you can purchase a UL 50E Listed enclosure with, for example, a Type 4X rating (watertight, dust-tight, and corrosion-resistant), this certification has a major caveat for anyone building a custom product.

The "Modification Voids the Listing" Trap

The minute you drill a hole, mill a cutout for a connector, or add a custom mounting bracket to a UL 50E Listed enclosure, its original listing is technically voided. Why? Because you have altered the construction that UL originally tested. The enclosure is no longer in its "as-certified" state. Your final, assembled product will still need to be evaluated by a UL field inspector or testing lab to certify the entire system.

Field Experience: The Data Center Power Unit Failure

We worked with a client building a power distribution unit for data centers in the US. They sourced an off-the-shelf, UL 50E Type 4 listed steel box, thinking it would streamline their UL approval. They then spent two days on their CNC machine milling over 30 openings for connectors, displays, and ventilation.

When the UL inspector arrived, he immediately failed the unit. The extensive modifications had compromised the enclosure's structural integrity and its certified NEMA rating. The client lost weeks and had to scrap the modified boxes.

We helped them redesign the enclosure from scratch in aluminum, incorporating all 30 cutouts into the initial CNC program. We provided them with documentation on the 6061-T6 alloy9 properties and material thickness, which they submitted to UL. The new design passed because it was evaluated as a complete system, built to the requirements of the final product standard from day one.

Engineer's Rule of Thumb: If your product requires significant custom cutouts, it's often more efficient to design a custom enclosure that meets the construction requirements of the target UL standard (e.g., UL 62368-1 for A/V and IT equipment) rather than buying a pre-listed box you intend to heavily modify.

So, what should I specify to my enclosure supplier?

You know your enclosure is critical, but asking for "UL/CE certified" is the wrong approach. You're an engineer, not a compliance lawyer. So how do you translate system requirements into a buildable design?

Stop asking for certifications. Start specifying performance. Provide your supplier with the functional requirements the enclosure must meet, referencing the standards your end-product must pass. This gives them actionable engineering targets to design against.

"rackmount enclosure"

"rackmount enclosure"

This shift from a compliance mindset to a performance mindset is the most important step you can take. Your enclosure manufacturer's job is to translate your performance needs into physical features. Instead of a vague request, your drawing notes and RFQ should contain specific, measurable targets.

A Practical Checklist for Enclosure Specification

Here is what you should be providing to an enclosure partner like Pumaycase. This allows us to design for compliance from the very beginning.

✅ Material & Finish:

- Don't Say: "Metal box."

- Do Say: "Material to be 6063-T5 aluminum alloy. All materials and finishes must be RoHS 3 compliant. Surfaces must be finished with black anodizing, MIL-A-8625, Type II, Class 2."

✅ Environmental Sealing:

- Don't Say: "Needs to be waterproof."

- Do Say: "Enclosure must provide IP67 sealing according to IEC 60529. A continuous silicone gasket is required between the main body and front/rear panels."

✅ EMC Shielding:

- Don't Say: "Good EMI shielding."

- Do Say: "Design must provide >70dB of shielding effectiveness from 100MHz to 2GHz. All panel joints must be electrically continuous. Specify appropriate conductive gasket material."

✅ Thermal Management:

- Don't Say: "Keep it cool."

- Do Say: "The enclosure must dissipate 25W of internal heat while maintaining an external surface temperature below 50°C in a 25°C ambient environment."

✅ Safety & Mechanical:

- Don't Say: "UL compliant."

- Do Say: "Design must include an M4 threaded hole for a chassis ground connection. The front panel must support a 15kg load without deflection. Construction must align with the material requirements of UL 62368-1."

By specifying performance, you empower your supplier to be a true partner. We've seen clients reduce EMC test-fail-retest cycles from three rounds to a single pass, saving weeks of schedule and thousands in lab fees, all because the design was right from the start.

Conclusion

Your enclosure isn't a simple box; it's a strategic engineering tool. Stop thinking of it as a compliance hurdle and start using it as the foundation for your product's reliability, safety, and performance.

Learn about the requirements and implications of CE certification for enclosures in the EU market. ↩

Explore the essential components of a Technical File to ensure your product meets compliance standards. ↩ ↩

Gain insights into the LVD and how it affects electrical safety in product design. ↩

Learn about the EMC Directive and how it ensures electromagnetic compatibility in products. ↩

Understand the materials restricted by the RoHS Directive to ensure compliance in your products. ↩

Learn about the ATEX Directive and its role in ensuring safety in explosive atmospheres. ↩

Find out the significance of UL Listing and how it impacts product safety and compliance. ↩

Explore the different NEMA/UL Type ratings and their relevance to product design. ↩

Learn about the benefits of using 6061-T6 aluminum alloy in enclosure design. ↩