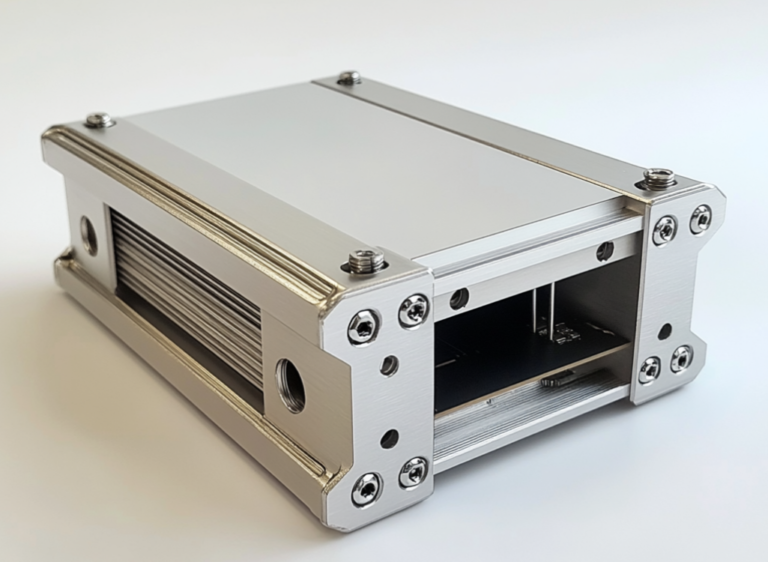

Aluminum extrusion enclosures are widely used across various industries due to their lightweight, durable, and thermally efficient properties. These enclosures are especially popular in electronics, industrial automation, telecommunications, and new energy applications. The flexibility of aluminum profiles allows for highly customizable designs, making them ideal for both standard and specialized uses.

Design Features of Aluminum Extrusion Enclosures

1. Lightweight and Strong

Aluminum 6061 and 6063 alloys offer an excellent balance of high strength and low weight, making these enclosures ideal for portable and industrial devices.

Advantages:

Easy to transport and install.

Reduces overall system weight without compromising durability.

- -

2. High Thermal Conductivity

Aluminum’s superior thermal conductivity makes it the perfect choice for enclosures housing heat-sensitive electronics.

Applications:

Passive cooling: Built-in fins and heat sinks enhance heat dissipation.

Common in power electronics, LED housings, and industrial controllers.

- -

3. Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it resistant to corrosion, especially when anodized.

Surface Treatments:

- Anodizing: Increases corrosion resistance and provides a sleek finish.

- Powder Coating: Adds an extra layer of protection and color customization.

Ideal for: Outdoor and marine environments, such as telecommunication base stations and solar inverters.

4. Customizable and Modular Design

Extrusion technology allows for complex cross-sectional shapes, enabling highly customizable enclosures with slots for PCBs, mounting rails, and ventilation.

Key Features:

- Modular construction: Enables easy assembly and expansion.

- Snap-fit designs: Reduce assembly time and cost.

- Customization options: Panel openings, screw holes, and integrated cooling fins can be tailored to specific needs.

Pro Tip: Modular designs offer flexibility for future upgrades without needing a complete redesign.

5. Excellent EMI/RFI Shielding

Aluminum enclosures act as natural Faraday cages, protecting sensitive electronic components from electromagnetic interference (EMI) and radio-frequency interference (RFI).

Applications:

Telecom and networking equipment

Medical instruments

Aerospace and defense systems

- -

Applications of Aluminum Extrusion Enclosures

1. Industrial Automation and Control Systems

- Used to house PLCs, motor controllers, and sensors.

- Durable and thermally efficient, ensuring reliable operation in harsh environments.

- Modular design allows easy integration into smart factory systems.

2. Electronics and Power Supplies

- Common in power inverters, battery management systems (BMS), and chargers.

- Built-in heatsinks for optimal thermal management.

- Compact designs for portable electronics.

3. Telecommunications and Networking

- Enclosures for 5G base stations, fiber optic converters, and wireless communication devices.

- IP65 or IP67-rated versions for outdoor use.

- Integrated EMI shielding ensures signal integrity.

4. New Energy and Renewable Systems

- Used in solar inverters, electric vehicle (EV) chargers, and energy storage systems.

- Withstands extreme environmental conditions with proper surface treatments.

5. Medical and Laboratory Equipment

Diagnostic instruments and control units benefit from aluminum’s corrosion resistance and ease of sterilization.

Supports precision electronics and displays with reliable EMI protection.

- -

Summary of Key Advantages

| Feature | Benefit |

|---|---|

| Lightweight and Strong | Easy to transport and reduces system weight |

| Thermal Efficiency | Enhanced cooling for heat-sensitive devices |

| Corrosion Resistance | Ideal for outdoor and harsh environments |

| Modular and Customizable | Supports flexible and scalable designs |

| EMI/RFI Shielding | Protects sensitive electronics from interference |

Conclusion

Aluminum extrusion enclosures offer a versatile and reliable solution for housing electronic and industrial devices. Their lightweight, customizable, and thermally efficient design makes them indispensable in industries like industrial automation, telecommunications, and renewable energy. With numerous customization options and excellent protection features, these enclosures are the perfect blend of performance and practicality for both standard and specialized applications.