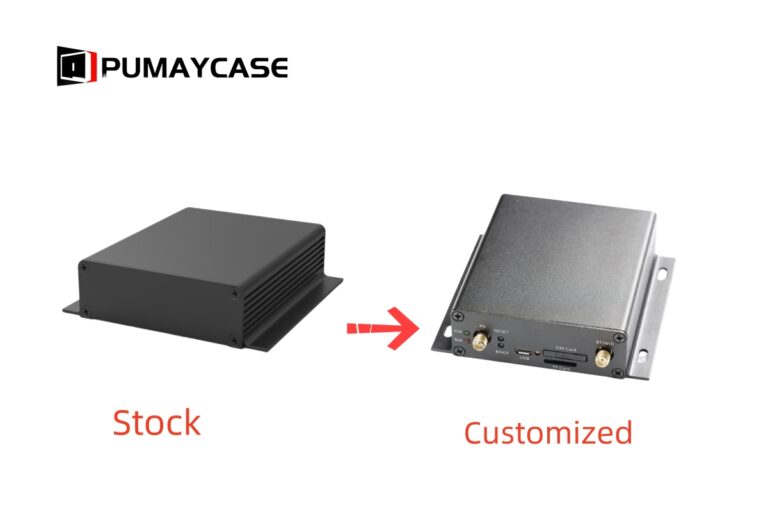

Custom Enclosures vs. Standard Enclosures: What’s the Difference?

Introduction

Choosing the right enclosure for your industrial electronic equipment1 can significantly impact your product's performance and longevity. One of the first decisions you’ll need to make is whether to use custom enclosures2 or standard (off-the-shelf)3 ones. At Pumaycase, we’ve been helping clients from industries such as telecommunications, medical devices, and industrial automation for over 12 years to select and customize enclosures that meet their unique needs. This article will help you understand the differences and determine which option is best for your project.

Custom Enclosures: Tailored for Specific Needs

Custom enclosures offer complete flexibility and personalization. They are designed and manufactured to match your exact specifications.

Technical Features of Custom Enclosures

- Material Selection: Choose from high-quality aluminum with optional surface treatments for corrosion resistance.

- Precision CNC Machining: Custom sizes, cutouts, and logo engraving options ensure a perfect fit and professional look.

- Optimized Design: Achieve optimal functionality, including improved heat dissipation and electromagnetic shielding.

Application Scenarios for Custom Enclosures

- Medical Equipment: Devices that require specific dimensions and panel layouts to house unique circuits and sensors.

- Aerospace and Defense: Enclosures for rugged and extreme environments, designed for durability and reliability.

- Research and Prototyping: University labs and R\&D centers needing small batches with precise specifications for experimental setups.

Brand Highlights: Why Pumaycase?

Unlimited Customization: From unique dimensions to personalized colors and logo printing.

Experience in Complex Projects: Pumaycase has worked with leading companies and research institutions worldwide to develop custom solutions.

Cost Efficiency in Small Batches: Thanks to our advanced CNC machining lines, we offer competitive pricing even for small-batch orders.

- -

Standard Enclosures: Cost-Effective and Readily Available

Standard enclosures are off-the-shelf solutions designed to fit common applications. They are ideal for companies with tight budgets or timelines.

Technical Features of Standard Enclosures

- Pre-Defined Sizes and Configurations: Ready to use for typical industrial devices.

- Affordable Pricing: Lower initial costs compared to custom options.

- Fast Lead Times: Available for shipment within 3-7 business days.

Application Scenarios for Standard Enclosures

- Consumer Electronics: Perfect for mass-produced devices with common form factors.

- Industrial Automation: Suitable for housing controllers, sensors, and communication modules.

- Prototyping: An excellent choice for quick proof-of-concept projects.

Brand Highlights: Why Choose Pumaycase Standard Enclosures?

Wide Range of Options: Over 100 designs and sizes to choose from.

High-Quality Materials: Made from durable aluminum with anodized finishes.

Quick Shipping: Our stock ensures minimal waiting time for your project.

- -

Which Option is Right for You?

The choice between custom and standard enclosures depends on your project’s needs, timeline, and budget. Here are some guidelines:

Custom Enclosures: Best for unique, high-performance requirements or brand-specific designs.

Standard Enclosures: Ideal for quick turnaround and cost-effective solutions for common applications.

- -

Conclusion

Both custom and standard enclosures have their advantages. At Pumaycase, we offer both options with unparalleled quality and customization services. Our team is here to help you choose the best enclosure for your project.

Ready to get started? Contact us at [Pumaycase]() to learn more about our enclosure solutions.

Discover essential tips for selecting the best enclosure to protect and optimize your industrial electronic devices. ↩

Explore the advantages of custom enclosures to enhance your equipment's performance and longevity. ↩

Learn about off-the-shelf enclosures and how they can save time and costs for your projects. ↩