Custom Enclosure

Engineered Metal Enclosures Tailored for Industrial Electronics

Customized Solutions to Meet Your Industrial Requirements

Why Choose PUMAYCASE

🔧 Proven Expertise

With over 12 years of experience in aluminum enclosure design and manufacturing, we confidently manage complex industrial projects with efficiency and precision.

✅ Quality Assurance

All enclosures are CE and SGS certified. Our strict quality control processes ensure product reliability and full compliance with international standards.

⚙️ Flexible Production

We support everything from low-volume prototypes to high-volume production runs—delivering on time to fit your development and scaling needs.

💬 Dedicated Support

Enjoy 24/7 online assistance and a dedicated account manager to ensure clear, responsive communication throughout your project lifecycle.

🚀 Continuous Innovation

Our commitment to R&D allows us to provide advanced enclosure solutions that stay ahead of market trends and evolving industrial demands.

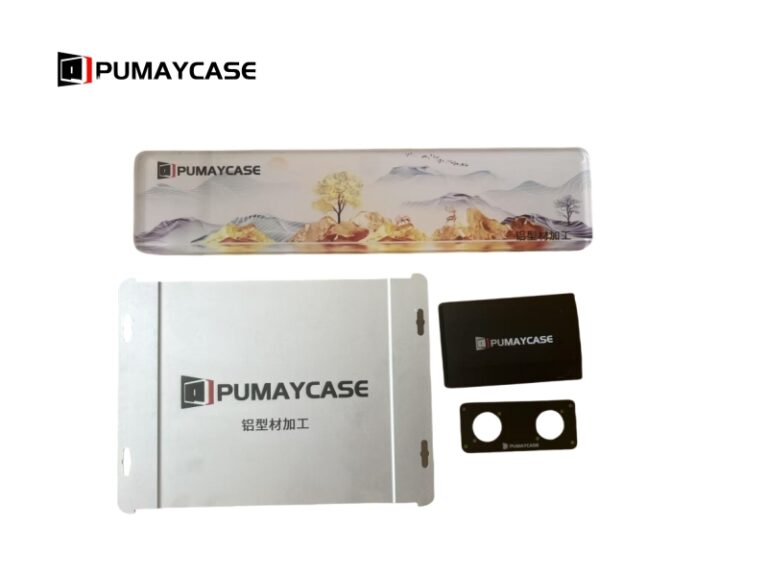

Customization Options

Available in a variety of standard sizes, or fully customized shapes based on your technical specifications.

Finishing options include anodizing, powder coating, sandblasting, brushing, and custom color treatments for functional and aesthetic consistency.

We support value-added machining such as logo printing, cutouts, mounting holes, ventilation slots, and other functional modifications.

Design & Engineering Support

Our structured design process bridges the gap between concept and production—ensuring every enclosure is built for performance, precision, and manufacturability.

📄 Requirement Submission

Send us your design specs, CAD files, or reference samples to get started.

🛠 Design Optimization

Our engineers collaborate with you to refine the design for improved performance and manufacturability.

🧪 Prototype Validation

For complex enclosures, we offer prototype sampling to verify fit, function, and design accuracy before full production.

⚙️ CNC Precision Manufacturing

Utilizing advanced CNC technology, we ensure high-precision enclosure production with consistent quality.

🚚 Global Logistics

We provide reliable international shipping—standard and expedited—through trusted logistics networks.

Manufacturing Capabilities

Our agile production system is built to support both rapid development and scalable manufacturing—ensuring flexibility, speed, and reliability.

⚡ Rapid Prototyping

Functional prototypes delivered within 1 week to accelerate your product development cycle.

🏭 Batch Production

Standard lead time is 15–18 days; flexible timelines available for complex or custom projects.

📦 Low Minimum Order Quantity

MOQs starting from just 10–20 units—ideal for early-stage development or pilot runs.

🌍 Global Logistics

Worldwide delivery with real-time tracking via trusted logistics partners.

Custom Enclosure Services

Our Mission: We are dedicated to providing world-class solutions for electronic equipment enclosures globally.

With a dedicated R&D department, marketing team, and production capabilities, we offer full custom design services to meet your specific needs and support aluminum enclosures with necessary modifications.

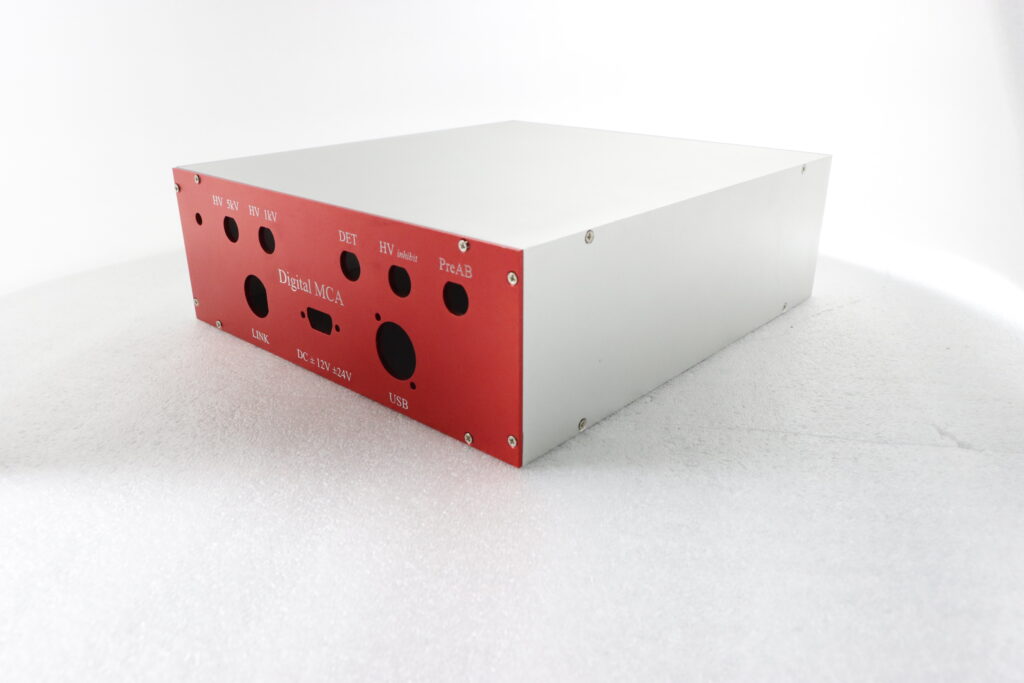

Custom Enclosure Services for Electronic Equipment

PUMAYCASE specializes in the design and manufacturing of high-quality custom enclosures for electronic equipment. From appearance to structure and functionality, we provide comprehensive solutions to bring your concepts to life and meet your specific requirements.

Our Mission: Delivering world-class enclosure solutions for electronic equipment worldwide.

With dedicated R&D, marketing, and production departments, we offer fully customized design services. Our team supports tailored modifications for aluminum enclosures, ensuring they align perfectly with your project needs.