Choosing Between 6061 and 6063 Aluminum: The Decision That Shapes Your Design

Choosing the wrong aluminum alloy can quietly wreck your design.\ It can compromise strength, ruin your surface finish, or inflate your machining costs — problems

If you have questions about material selection, product design, mold design, electronic enclosure service, our team is here to assist you with expert guidance and valuable insights tailored to your needs.

Choosing the wrong aluminum alloy can quietly wreck your design.\ It can compromise strength, ruin your surface finish, or inflate your machining costs — problems

You’ve built a fantastic piece of industrial tech — and you’re ready to ship it worldwide.\ Then come the questions: ECCNs, dual-use, export control, licensing.

A product fails in the field, and your customer is frustrated. The return process is confusing and slow, eroding the trust you worked so hard

Your enterprise customers are starting to ask about your ESG score. You’re getting questions about recycled content1 and carbon footprint2s. Suddenly, sustainability isn’t just a

Your startup has a brilliant new industrial device, but the clock is ticking. Custom enclosures seem slow and expensive, threatening your launch timeline and burning

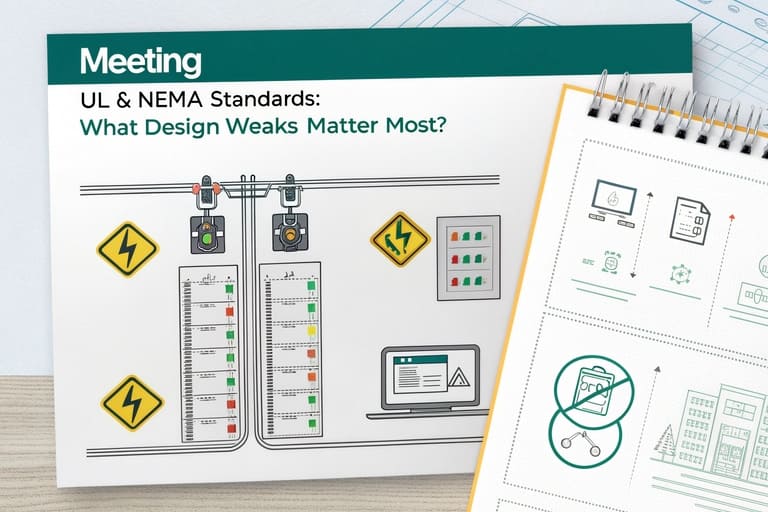

Your product is ready, but a failed UL or NEMA test looms. One small oversight in your enclosure design could mean costly rework, missed deadlines,

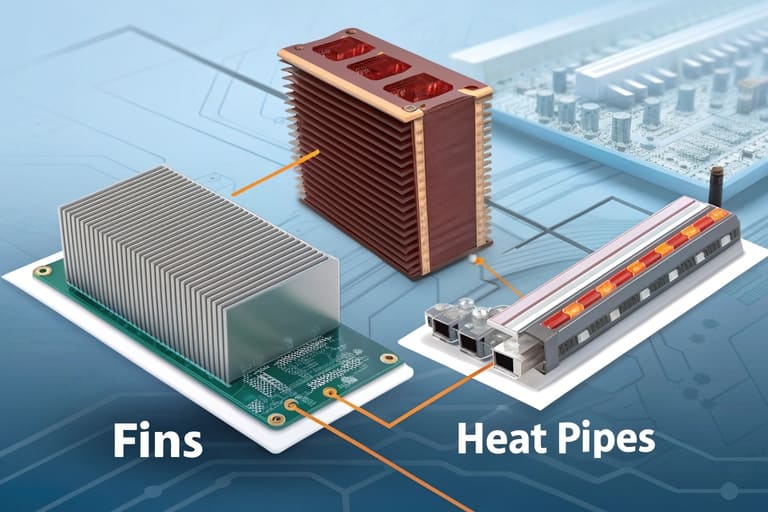

Your powerful electronics are overheating inside a sealed box. This thermal throttling kills performance, and adding a fan is not an option. You’re stuck with

Your project is behind schedule because a container of parts is stuck at sea. The long, unpredictable lead times and surprise tariffs from overseas suppliers

Your detailed CAD model is done, but now you face hours of creating separate drawings and BOMs. A single design change creates a cascade of

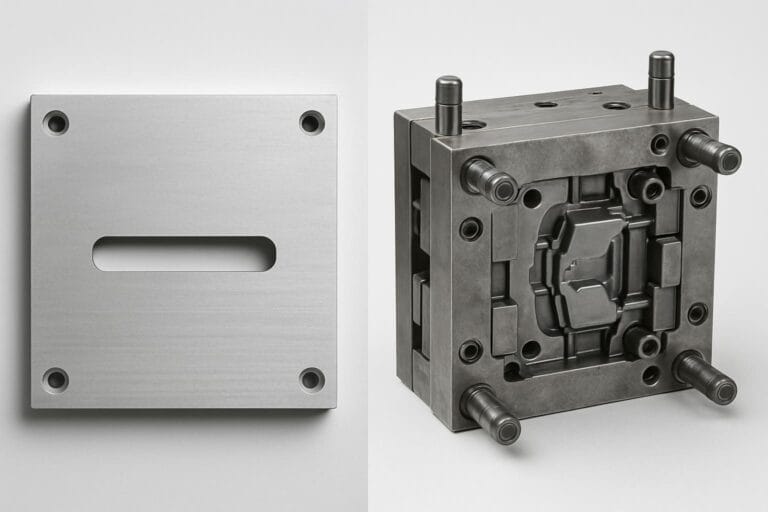

Ever send a perfect 3D file to a supplier and wonder about the mysterious process that turns it into a physical part? This "black box"

You need a functional prototype for testing yesterday, but the quoting process is dragging on. This endless back-and-forth wastes precious time, pushing back your entire

Choosing an aluminum alloy feels like a minor detail. But the wrong choice leads to overheating, corrosion, and failed products. Let’s get this critical decisionright.

You’ve finalized your PCB, but the quote for your custom enclosure lands on your desk, and it’s over budget. Now you’re caught between defending the

Facing the maze of product certification can feel like a last-minute roadblock. You’ve perfected the electronics, but now you’re decoding compliance standards. Let me give

That low unit price from an overseas supplier looks great in your budget spreadsheet. But weeks later, surprise invoices for brokerage, tariffs, and inland freight

You’ve spent months perfecting a design, only to hand over your high-value aluminum enclosures to a shipping container for a 30-day journey. A single forklift

You have a critical project, but choosing a new enclosure supplier feels like navigating a minefield. Pick wrong, and you’re facing months of delays and

You found an off-the-shelf box that almost fits, but it lacks proper mounting, overheats, and looks unprofessional. Now you’re facing field failures and a product

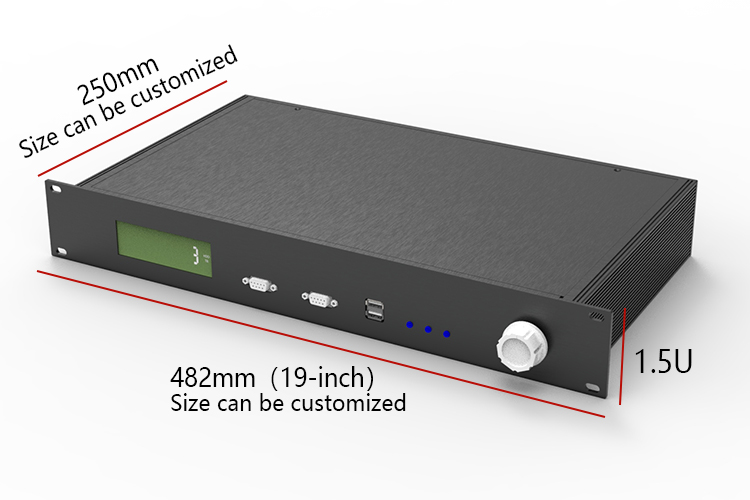

How Can I Procure 2U Rackmount Cases Efficiently and Without Risk? Your 2U rackmount project is approved, but sourcing the enclosure feels like a gamble.

You’ve perfected the enclosure design, but now face international payment terms1. Choosing wrong means risking your deposit or, worse, receiving a batch of out-of-spec parts

Choosing the right supplier for your 19-inch rack enclosure1 is critical. A bad choice can lead to delays, poor quality, and a product that fails

Your custom electronics won’t fit a standard rack enclosure. Trying to modify it yourself leads to messy results and potential damage, undermining the professional quality1

You’ve built impressive electronics, but the off-the-shelf rack enclosure makes them look cheap. Misaligned holes and ill-fitting panels compromise your product’s quality and your brand’s

You need to verify a supplier’s quality before committing. But ordering a sample feels like a black box, causing uncertainty. Will it be what you

Sourcing from China feels risky. You worry about scams, poor quality, and communication breakdowns that can derail your project and budget. This uncertainty is stressful

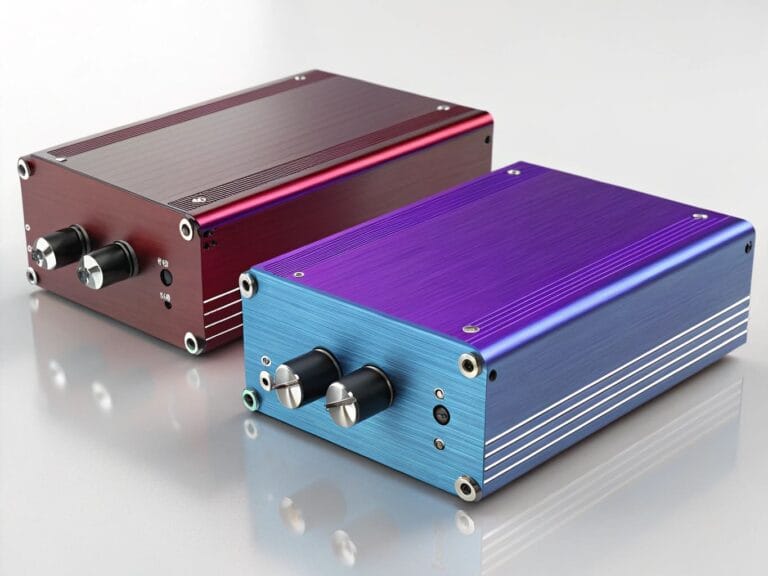

You’ve designed a great product, but the finish on its enclosure scratches easily and corrodes. This makes your premium device look cheap and unreliable. Anodizing

Your sensitive electronics[^1] are failing or giving weird readings. You suspect electromagnetic interference[^2] (EMI) is the culprit, but your standard metal box isn’t helping. Effective

Your high-performance electronics are failing in the field. An enclosure seems like just a box, but a poor design can cripple your device. Smart design

Are you overlooking shock resistance in your enclosure designs? A single drop or vibration can cause catastrophic failures, expensive repairs, and costly downtime[^1]. Shockproof aluminum

Worried about inconsistent quality in aluminum panel processing? Inaccurate cuts or surface flaws not only increase costs but compromise your product’s overall reliability and performance.

Click to Chat

I am online now

Hello. This is Jessie from Pumaycase, How can I assist you today?

WhatsApp Us

🟢 Online | Privacy policy