Your startup has a brilliant new industrial device, but the clock is ticking. Custom enclosures seem slow and expensive, threatening your launch timeline and burning through your limited cash.

Yes, absolutely. For startup hardware, aluminum extrusion enclosures are the fastest path to market because they have very low tooling costs, leverage a huge library of existing profiles, and allow for extremely rapid design changes.

"Rapid Launch with Aluminum Extrusion Enclosures"

"Rapid Launch with Aluminum Extrusion Enclosures"

I've seen so many startups get stuck at the enclosure stage. They spend months and tens of thousands of dollars on custom molds for plastic or die-cast parts, only to find they need to make a change. The beauty of extrusion is that it flips this entire process on its head. I remember working with a small team developing a new sensor hub. They were convinced they needed a complex, custom-molded plastic box. After seeing the tooling quote, they came to us in a panic. We showed them how an existing extrusion profile could work. We just needed to cut it to length and create two simple end plates. They went from a 12-week tooling delay to holding a finished prototype in less than two weeks. It was a complete game-changer for them, and it's a story I see repeat itself constantly.

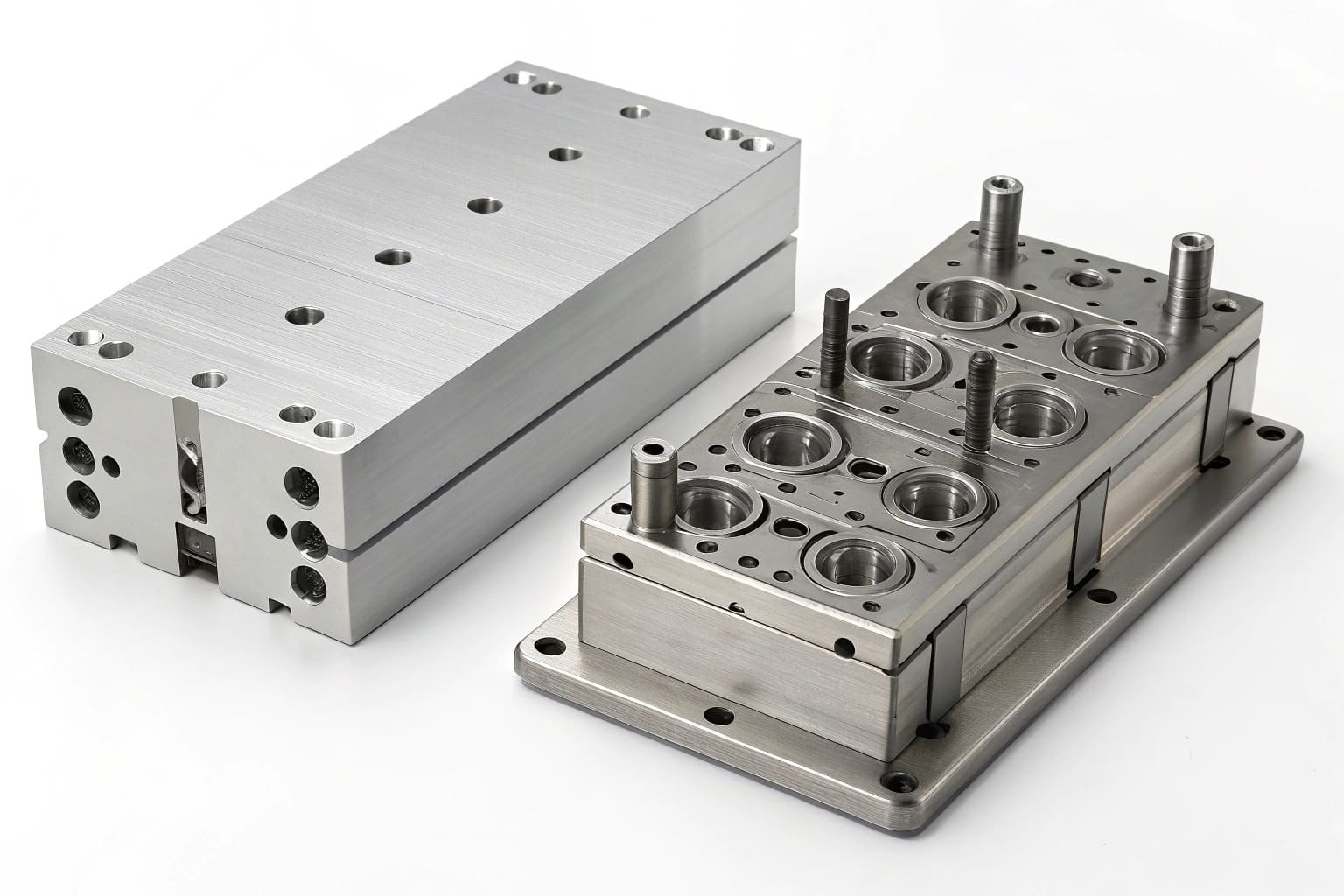

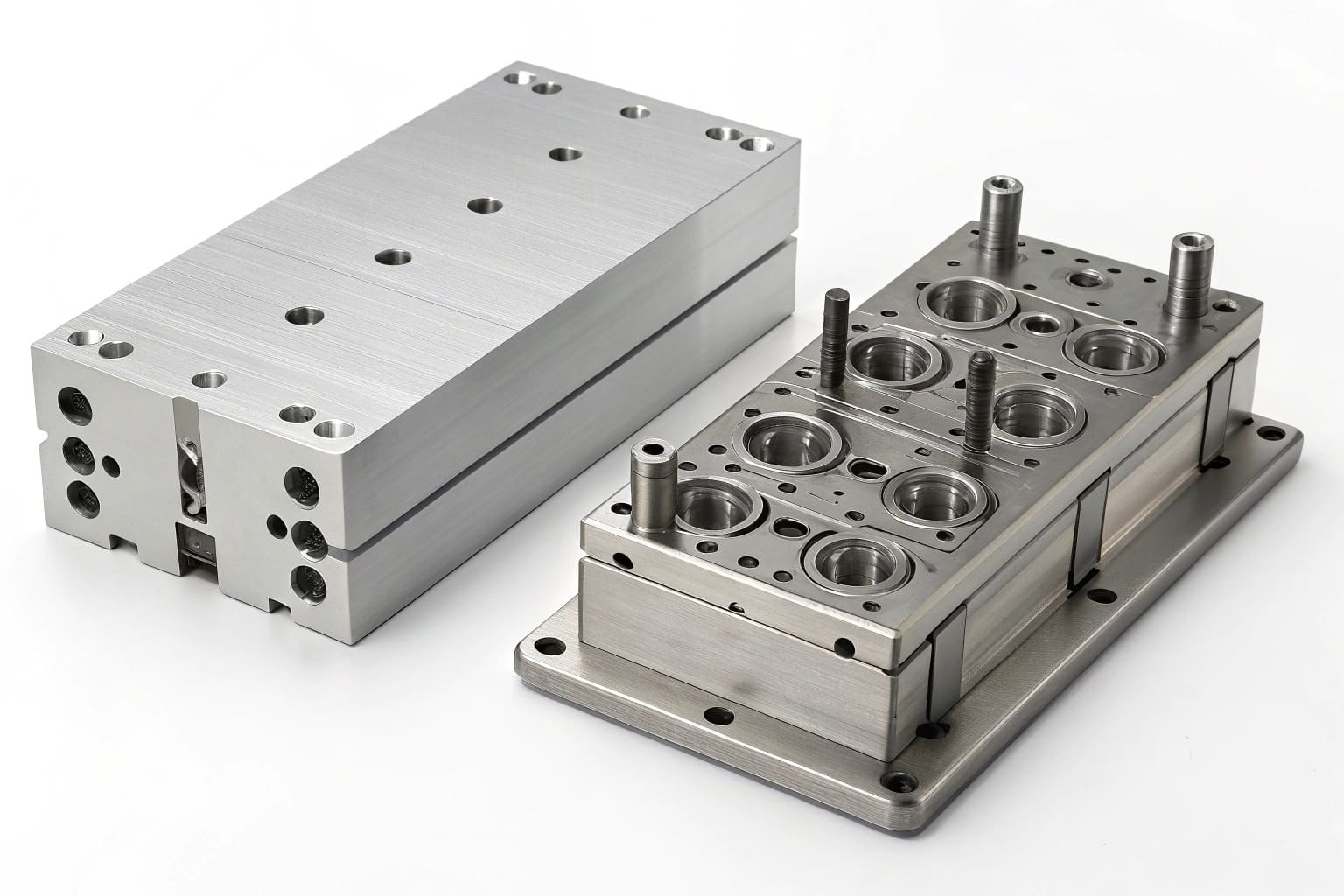

How Can You Avoid Massive Upfront Tooling Costs?

You need a custom-sized case, but injection molding quotes[^1] are shocking. These huge tooling fees drain your startup's runway before you've even sold a single unit.

You avoid these massive costs by choosing aluminum extrusion. The die needed to create a custom profile costs hundreds of dollars, not the tens of thousands required for injection molding, preserving your critical startup capital.

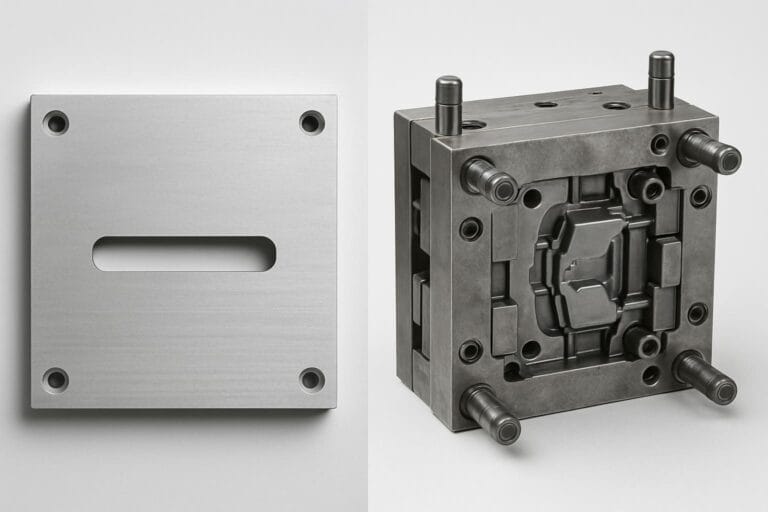

"Comparing Low Tooling Costs of Extrusion vs. Molding"

"Comparing Low Tooling Costs of Extrusion vs. Molding"

The secret to the low tooling cost of aluminum extrusion lies in the simplicity of the tool itself. An extrusion die is basically a hardened steel disc with a shape cut out of it, like a very robust cookie-cutter. Hot aluminum is pushed through it to create the profile. In contrast, an injection mold for plastic or a die-casting mold is an incredibly complex piece of engineering. It has multiple parts, cooling channels, ejector pins, and intricate cavities that must fit together with extreme precision. The cost to design and build one of these molds can easily be the biggest single expense in a hardware project. For a startup, spending that much capital on a "box" before you've validated your product is a huge risk. Extrusion lets you bypass that risk almost entirely, freeing up cash for what really matters: your electronics and software.

The Financial Reality: Die vs. Mold

| Feature | Aluminum Extrusion Die | Plastic Injection Mold / Die-Cast Mold |

|---|---|---|

| Typical Cost | $500 - $2,000 | $10,000 - $100,000+ |

| Lead Time | 1 - 2 Weeks | 8 - 16 Weeks |

| Modification Cost | Low (make a new die) | Very High (requires re-machining steel) |

| Ideal For | Startups, prototyping, low-to-high volume | High-volume, mass-market products |

Can You Really Skip the Design Phase and Still Get a Custom Fit?

You have standard components but no time for a full custom design from scratch. Every day spent designing an enclosure is a day you're not selling your product.

Yes, you can. By starting with a standard profile from a ready-to-use library, you skip the most time-consuming part of the design process. You just need to specify the length and design custom end plates.

"PUMAYCASE's Ready-to-Use Profile Library"

"PUMAYCASE's Ready-to-Use Profile Library"

One of the biggest accelerators we offer is our extensive library of off-the-shelf extrusion profiles. We have hundreds of designs already created, tested, and ready to go. These aren't just simple boxes; they include profiles with integrated heat sinks, T-slots for mounting, and internal grooves for sliding in PCBs. The process for a rapid launch becomes incredibly simple. You look through our catalog and find a profile that fits the general size and features you need. Then, you just tell us the exact length you want. The only "custom" design work left is creating the two simple, flat end plates that seal the enclosure. This modular approach[^2] cuts the enclosure design process from weeks or months down to just a few days. It's a plug-and-play system for hardware, allowing you to get a professionally finished and perfectly sized enclosure with minimal engineering effort[^3].

Your Fast-Track Design Process

- Browse & Select: Choose a standard extrusion profile from our library that meets your needs for width, height, and features (e.g., cooling fins).

- Specify Length: You tell us the exact length required to house your components. We cut the profile to your precise specification.

- Design End Plates: You (or we) design two simple, flat aluminum end plates with cutouts for your connectors, buttons, and LEDs.

- Assemble: The parts fit together perfectly. You get a robust, market-ready enclosure in record time.

What if Your PCB Layout Changes Last Minute?

Your board design changed, and your expensive prototype enclosure is now useless. Redoing a molded case means more tooling costs and massive delays, killing your momentum.

With an aluminum extrusion enclosure, you can adapt your design in hours, not months. If your PCB changes, you likely only need to modify the simple, flat end plates, allowing for a new prototype in days.

"Rapid Iteration for Last-Minute Design Changes"

"Rapid Iteration for Last-Minute Design Changes"

This is where the agility of aluminum extrusion truly shines for a startup hardware team. We all know that designs change. A connector moves, a port is added, a heatsink needs to be bigger. If you're using a molded plastic case, a change like this is a disaster. It means expensive and time-consuming modifications to the steel mold, if it's even possible. You could be facing another 8-week delay. With our extrusion-based system, a change is trivial. Since the main body of the enclosure is a standard profile cut to length, a change to your PCB layout usually only affects the end plates. You simply send us an updated CAD file for the end plate, and we can machine a new one for you in a day or two. This allows you to iterate on your hardware design almost as quickly as you can iterate on your software.

Adapting at the Speed of a Startup

| Change Scenario | With Molded Enclosure | With Extrusion Enclosure |

|---|---|---|

| Move a connector | Mold modification needed. Cost: $1,000s. Delay: 4-8 weeks. | Update CNC file for end plate. Cost: <$100. Delay: 2-3 days. |

| Change enclosure length | New mold needed. Cost: $10,000s. Delay: 8-16 weeks. | Specify a new cut length. Cost: $0. Delay: None. |

| Need a prototype | Must wait for full tooling. 8-16 weeks. | Machine from stock. 1-2 weeks. |

Conclusion

For a rapid launch, aluminum extrusion enclosures offer the best combination of low tooling cost, speed, and flexibility, making them the ideal choice for hardware startups.

---

[^1]: Understand the cost factors behind injection molding and how to manage them.

[^2]: Learn how a modular approach can simplify your design process and save time.

[^3]: Explore strategies to reduce engineering effort while maintaining product quality.