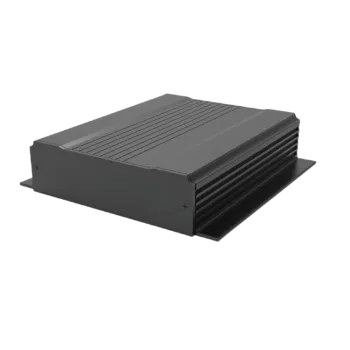

Aluminum Extrusion Electronics Enclosure Manufacturing

Looking for High-Quality Aluminum Enclosures for Your Industrial Electronics?At PUMAYCASE, we specialize in providing durable and innovative aluminum enclosures designed to optimize your industrial applications. Whether you need standard designs or customized solutions tailored to your needs, we are here to help. Don’t settle for less—reach out today for a tailored consultation and discover how we can support your business growth!

Your Trusted Partner for Industrial Aluminum Enclosures

Custom Aluminum Enclosures Designed to Meet Your Exact Requirements

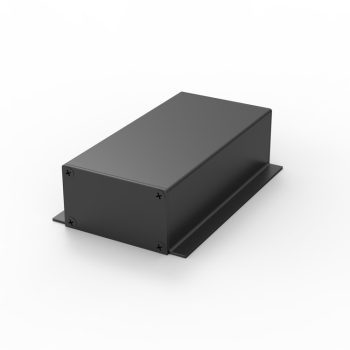

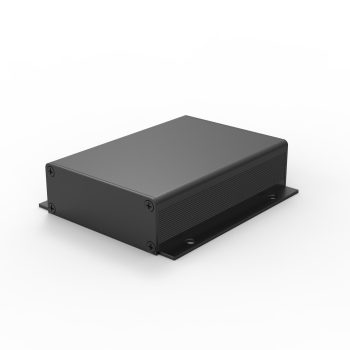

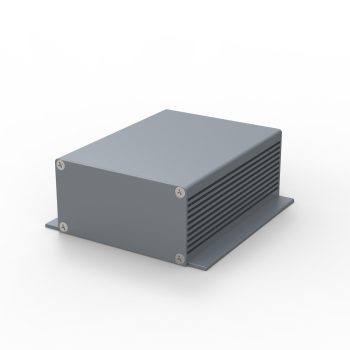

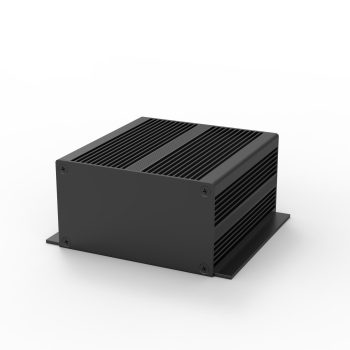

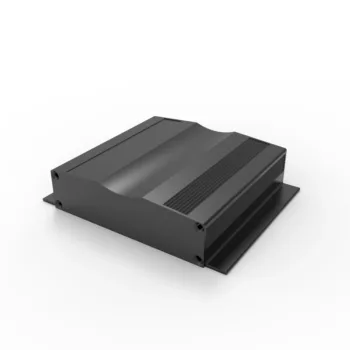

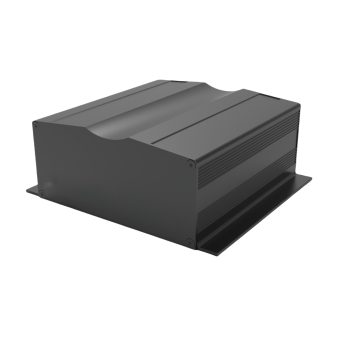

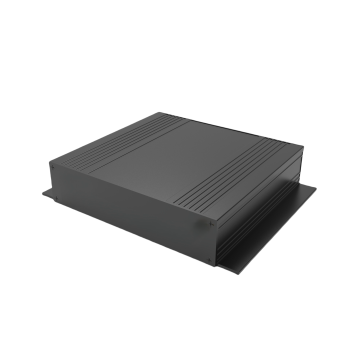

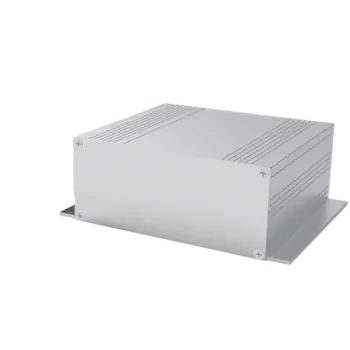

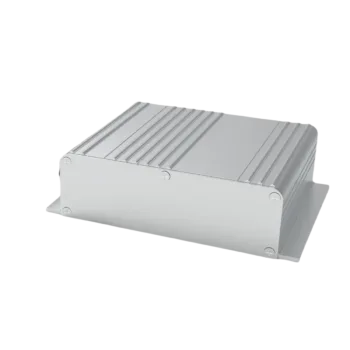

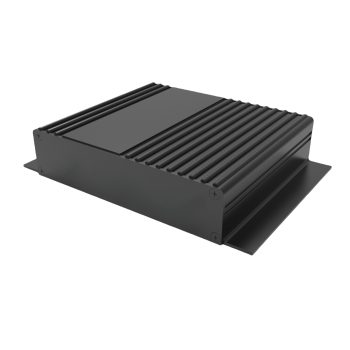

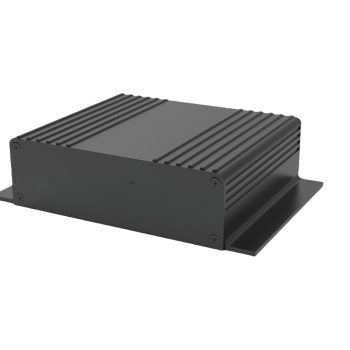

Shape and Design Options: Choose from a variety of enclosure shapes, such as rectangular, circular, or completely custom designs. Tailored features like mounting flanges, vents, and access points ensure seamless integration with your devices.

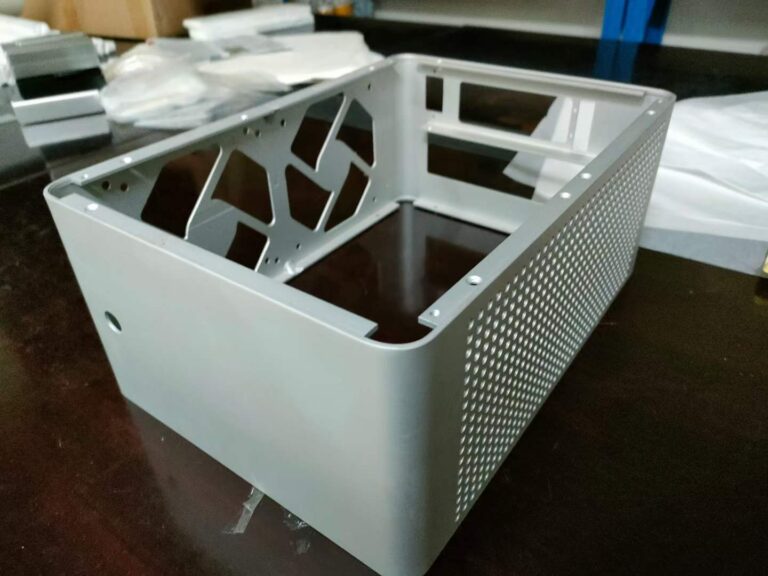

Precision Panels and Construction: Each enclosure is meticulously engineered with precise dimensions, sturdy wall construction, and reinforced corners. Options like perforated or slotted panels are available to accommodate cooling or cable management needs.

Structural Reinforcements: Reinforced frames, top and bottom plates, and added support for internal components provide enhanced strength, ensuring reliable performance in demanding industrial applications.

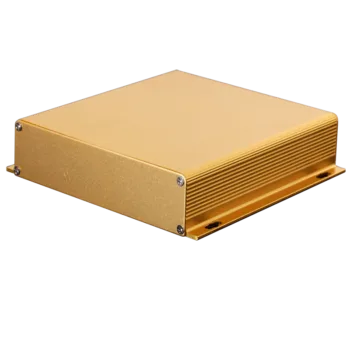

Custom Coating Options: In addition to design customization, we provide advanced coatings, including anodized finishes, powder coatings, and EMI shielding, tailored to enhance protection, conductivity, and aesthetic appeal.

Let’s collaborate to create an enclosure solution perfectly suited to your industrial electronic needs, combining quality, innovation, and exceptional performance.

Beyond Aluminum Enclosures: PUMAYCASE Delivers Tailored Solutions

Choosing the right material or design features for your aluminum enclosure can be complex. Our experienced team will help you select the ideal alloy, finish, and structural features to ensure your enclosure performs flawlessly in its intended environment..

From design refinement to performance optimization, our technical experts are here to assist at every stage. Whether it’s remote consultations or on-site engineering support, we work closely with you to ensure your enclosure exceeds expectations..

Backed by years of expertise, we deliver precision-engineered aluminum enclosures that meet the highest industry standards. Whether it’s unique geometries, advanced surface treatments, or specialized coatings, we provide the perfect solution to match your technical and operational needs..

Why Choose PUMAYCASE?

At PUMAYCASE, we bring years of expertise and innovation to the design and manufacturing of industrial electronics aluminum enclosures. Our custom solutions are tailored to your specific needs, making us the reliable partner for your enclosure requirements. By choosing PUMAYCASE, you benefit from top-tier quality, precision engineering, and customer-focused service designed to support your business growth..

Flexible Production

Whether you need a single enclosure prototype or a large-scale production run, PUMAYCASE’s adaptable manufacturing processes ensure efficiency and consistency, no matter the order size..

Precision in Design

With extensive experience in enclosure design, our skilled team delivers solutions that meet the highest industry standards for durability, functionality, and aesthetics.

Cost-Effective Manufacturing

Our optimized production strategies deliver high-quality aluminum enclosures at competitive prices, helping you manage costs without compromising on quality.

Customer-First Commitment

At PUMAYCASE, your satisfaction drives everything we do. From responsive communication to products crafted with precision to meet your exact needs, we prioritize your business success.

On-Time Delivery

Our streamlined processes and operational efficiency ensure your enclosures are delivered promptly, keeping your projects on schedule.

Comprehensive Enclosure Solutions

Equipped with state-of-the-art tools and expertise, PUMAYCASE offers a wide array of enclosure options, from standard designs to fully customized solutions for industrial electronic devices.

Production Process

Material

Cut Material

Drill Screw holes

CNC milling

CNC Laser

Bend

Finish

Logo Print

Your Comprehensive Guide to Procuring Aluminum Enclosures

Aluminum enclosures are essential components across various industries, including industrial electronics, telecommunications, medical devices, and automation systems.Whether you are sourcing enclosures for a specific project or looking to enhance your supply chain, this guide offers everything you need to make informed decisions. From selecting the right materials and finishes to exploring customization options and technical specifications, we’re here to help you navigate every step of the process.

Table of Contents

1. What is an Aluminum Enclosure?

At PUMAYCASE, our aluminum enclosures are specifically engineered to meet the needs of industries such as industrial electronics, telecommunications, and automation, ensuring that your sensitive electronic devices are well-protected in even the harshest conditions.

Enclosure have 2 structure, Tube and Split.

2.Key Features of Aluminum Enclosures

Corrosion-Resistant: Aluminum naturally resists corrosion, making it ideal for applications in challenging environments, including outdoors and in coastal regions.

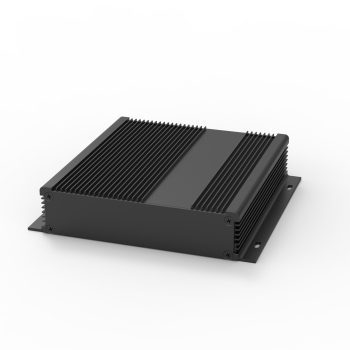

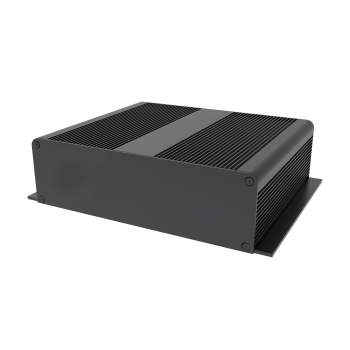

Thermal Management: Aluminum’s excellent thermal conductivity ensures that heat generated by electronic components is dissipated efficiently, preventing overheating.

Customizable Design: At PUMAYCASE, we offer a wide range of custom options, from dimensions and cutouts to finishes, ensuring your enclosure fits perfectly for your unique project needs.

Versatility: Suitable for various industries, including automation, control systems, and power electronics, aluminum enclosures can be adapted to a variety of applications.

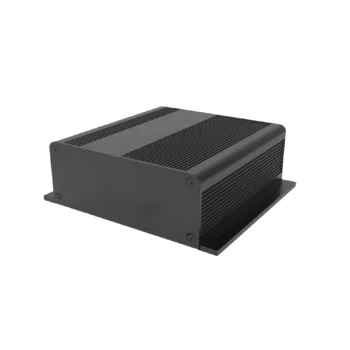

3. Aluminum Enclosure Specifications

Materials: We use high-quality aluminum alloys such as 6063,5052 and 6061, which provide superior strength, corrosion resistance, and formability.

Thickness: Standard wall thickness ranges from 1.5mm to 3mm, ensuring a balance of durability and lightweight construction.

Custom Sizes: Enclosures are available in a wide range of sizes or can be custom-designed based on your specifications.

Surface Finish: Options include anodizing, powder coating, or brushing, providing durability, aesthetics, and additional environmental protection.

Mounting Options: Custom pre-fitted holes or brackets are available for easy internal component mounting.

4. Types of Aluminum Enclosures

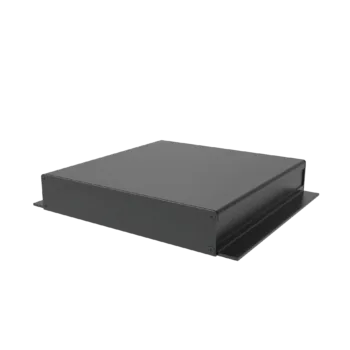

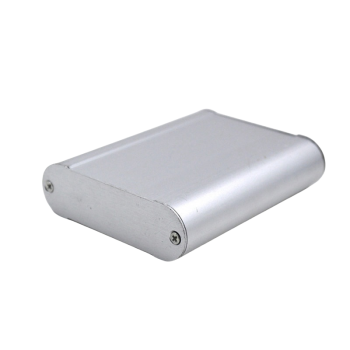

Handheld Enclosures: Lightweight and portable, these enclosures are perfect for field devices or testing equipment, with easy-to-hold designs.

DIN Rail Enclosures: Designed for mounting on DIN rails in control cabinets, these enclosures are essential for industrial automation systems.

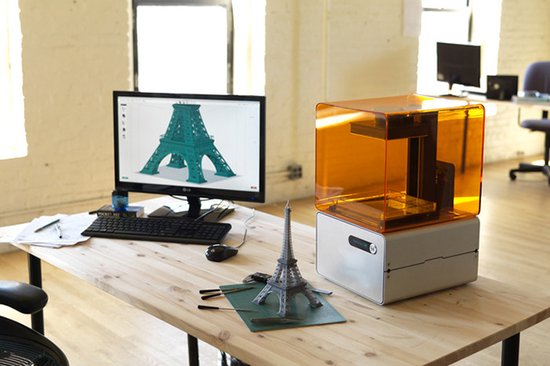

Desktop Enclosures: Robust and aesthetically designed for office or lab environments, ideal for housing computing or networking equipment.

Custom Enclosures: PUMAYCASE specializes in creating tailor-made enclosures for clients in sectors like telecommunications, aerospace, and industrial automation, ensuring a perfect fit for your specific project needs.

5. Applications of Aluminum Enclosures

Telecommunications: Used to house networking equipment, routers, and base stations, safeguarding sensitive electronics from moisture, dust, and physical impact.

Energy and Power: Designed for power systems, electrical panels, and renewable energy systems, aluminum enclosures protect components in environments with high electrical demands.

Medical Equipment: Provides robust protection for medical devices and testing instruments, ensuring compliance with health and safety standards.

Transportation and Aerospace: Enclosures for aerospace or automotive applications, providing rugged protection against vibrations, extreme temperatures, and harsh conditions.

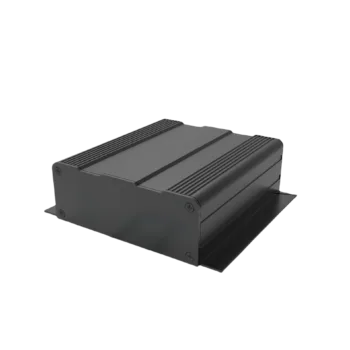

6. Customization Options for Aluminum Enclosures

Custom Sizes: We can manufacture enclosures to your exact dimensions, ensuring a perfect fit for your electronic components.

Cutouts and Openings: Tailored cutouts for connectors, vents, or cable glands can be easily integrated into your enclosure design.

Surface Finishes : Choose from anodized, powder-coated, or brushed finishes for improved durability, aesthetic appeal, and environmental protection.

Mounting Solutions: Custom internal brackets or mounts are available to securely hold your equipment within the enclosure. Color and Branding: We can powder coat enclosures in any color, allowing you to match your company’s branding or differentiate products.

7. How to Customize Your Aluminum Enclosure?

Determine Your Requirements: Identify the size, environmental conditions (e.g., exposure to moisture, dust, or extreme temperatures), and functionality of your project.

Choose the Material and Finish: Select the appropriate aluminum alloy, thickness, and surface treatment (anodizing, powder coating, etc.).

Specify Features: Determine if you need custom cutouts, mounting holes, or internal brackets to accommodate your electronic components.

Collaborate with Our Design Team: Work with our engineers to create a design that fits your needs. We can provide prototypes for testing before mass production.

Approval and Production: Once the design is finalized, we move forward with manufacturing and provide you with a quality-tested product.

8. Maintenance and Care of Aluminum Enclosures

Regular Cleaning: Clean the exterior and interior with a soft cloth and mild soap or detergent. Avoid using abrasive materials that can scratch the finish.

Inspect for Wear: Periodically check for any dents, cracks, or damage, especially in areas subjected to heavy use or harsh environments.

Prevent Chemical Exposure: While aluminum is resistant to many chemicals, avoid exposure to strong acids or alkalis that can damage the surface.

Protection from Extreme Environments: In highly corrosive environments, consider additional protective coatings or seals to ensure long-term performance.

9. How to Find a Reliable Aluminum Enclosure Manufacturer?

Industry Expertise: Choose a manufacturer with deep experience in designing and producing enclosures for industrial applications.

Customization Capabilities: Ensure the manufacturer offers customization services to meet your specific needs, including custom sizes, cutouts, and finishes.

Quality Assurance: Look for key certifications to ensure the manufacturer adheres to strict quality control processes.

Customer Support: A reliable manufacturer should provide excellent customer service, assisting you from design through to delivery.

Client Testimonials: Check reviews or case studies from other businesses to ensure the manufacturer can deliver on time and meet your specifications.

In Summary

Custom Your Aluminum Enclosure Today with Ease!

Whatever your aluminum enclosure requirements, PUMAYCASE ensures precision-crafted solutions tailored to your specifications. With our extensive expertise and strict quality control, we deliver top-tier enclosures that balance durability, functionality, and affordability. Partner with us for exceptional value and solutions designed to meet your industrial needs.