Choosing the wrong aluminum alloy can quietly wreck your design.\

It can compromise strength, ruin your surface finish, or inflate your machining costs — problems that don’t show up until it’s too late, when prototypes fail or field repairs pile up.

The good news? Once you understand how 6061 and 6063 differ, the choice becomes obvious.\

Use 6063 when you need elegant extrusions and a flawless finish. Use 6061 when you need strength, rigidity, and machining precision.

Insight: Alloy selection is the first “design decision that decides everything else.” Treating it as an afterthought is what separates rework from reliability.

When Is 6063 the Right Choice?

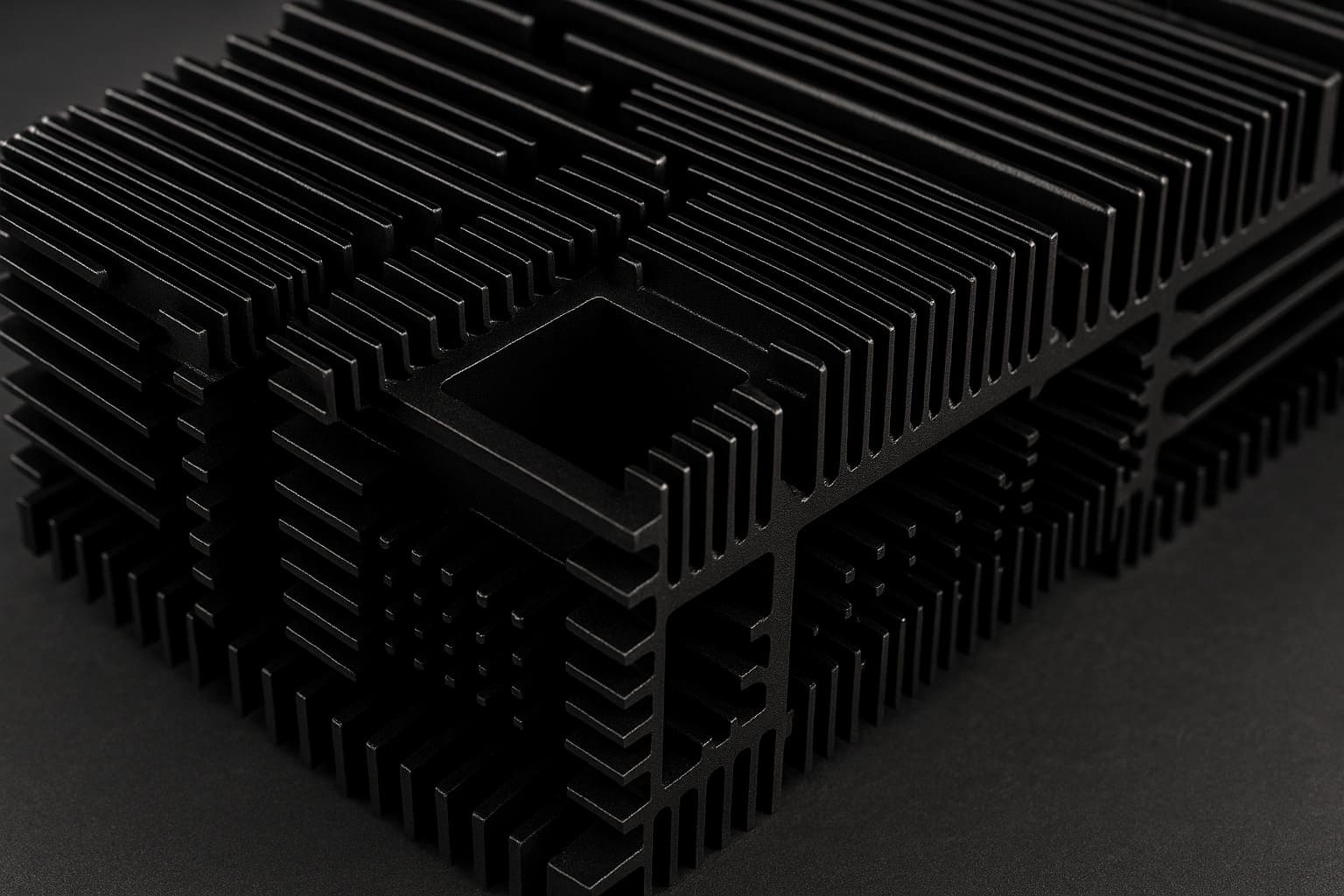

If your goal is to build a sleek, modern enclosure — perhaps with heatsink fins, curved edges, or slide-in slots — you’re designing in 3D artistry, not brute force.\

That’s where 6063 aluminum shines.

It’s often called the architectural alloy, used in window frames, decorative trims, and precision extrusions. Its unique chemical balance lets molten aluminum flow smoothly through dies, capturing every curve and channel of your design.

The Artist’s Alloy

When a heated 6063 billet is pushed through an extrusion die, it behaves like metal silk — filling even the thinnest fins or slots.\

That fluidity allows you to integrate heatsinks, grooves, and PCB guides directly into the profile, reducing post-machining and improving consistency.\

Its fine grain structure also gives a surface that anodizes beautifully, creating a deep, uniform metallic sheen that 6061 can’t match.

| Feature | 6063 Alloy | Why It Matters |

|---|---|---|

| Extrudability | Excellent | Enables intricate shapes, thin fins, and detailed features. |

| Surface Finish | Excellent | Produces smooth, premium surfaces ideal for anodizing. |

| Strength | Good | Sufficient for most electronics, but not heavy loads. |

| Best For | Consumer devices, audio amps, lab gear — anything design-conscious. |

Insight: With 6063, form is function — its beauty comes from the same precision that makes it efficient.

When Do You Need 6061?

When your product lives on the factory floor or the field — bolted to machinery, exposed to vibration, or absorbing shock — strength comes first.\

That’s when you reach for 6061-T6 aluminum, the engineer’s alloy.

The Engineer’s Alloy

The T6 temper gives 6061 almost twice the tensile strength of 6063. It doesn’t deform under load, and it resists fatigue far longer in demanding environments.\

That’s why it’s used in robotics, vehicles, aerospace components — anywhere failure isn’t an option.

Machinability is another advantage. On a CNC mill, 6061 cuts cleanly, producing crisp threads and precise pockets.\

6063, by contrast, is softer and tends to gum up tooling, requiring slower speeds and extra care.

I once worked with an engineer named Jeff designing a mounting plate with hundreds of tapped holes. His choice of 6061 saved hours of machining time and gave the rigidity his design demanded.

| Feature | 6061-T6 Alloy | Why It Matters |

|---|---|---|

| Tensile Strength | \~45,000 psi | Survives vibration, impacts, and stress with ease. |

| Machinability | Excellent | Ideal for deep milling, drilling, and threading. |

| Extrudability | Fair | Suited for simpler shapes only. |

| Best For | Structural parts, rugged housings, or heavily machined components. |

Insight: 6061 is less about beauty and more about confidence — knowing your enclosure will outlast the system it protects.

How Do They Compare in Cost?

Many engineers assume cost differences start with material price.\

In reality, the alloys cost nearly the same per kilogram — it’s your manufacturing process that determines the final number.

Look Beyond Material Price

If your design relies on complex extrusions — deep fins, intricate channels — 6063 saves money because it extrudes faster, wears out dies less, and minimizes post-machining.\

Try the same shape in 6061, and you’ll spend more on tooling, cycle time, and potential scrap.

Conversely, if your design is a simple solid block needing extensive CNC work, 6061 wins. It machines faster, produces cleaner results, and cuts your machining hours.

| Scenario | Recommended Alloy | Why It Saves Cost |

|---|---|---|

| Complex extrusions with heatsinks | 6063 | Fast, smooth extrusion lowers cycle time. |

| Simple billet parts with many holes | 6061 | Machines faster with less tool wear. |

| Premium consumer devices | 6063 | Beautiful anodized finish reduces rework. |

Insight: Alloy choice doesn’t just affect performance — it decides where your money goes: into tooling or machining time.

Final Takeaway

If your design needs beauty, precision, and intricate extrusion, choose 6063.\

If it demands strength, endurance, and aggressive machining, choose 6061-T6.

The alloy you pick shapes everything that follows — your tooling, your finish, your assembly process, even how customers feel about the product in their hands.