Choosing the right panel1 for an enclosure or equipment depends on several factors, including functionality, aesthetics, environmental conditions, and material properties2. The panel serves as the interface between users and internal components, and selecting the right one ensures reliability, ease of use, and protection3.

Here’s a step-by-step guide to selecting the best panel based on your project’s specific needs.

1. Identify the Project Requirements

Key Questions to Consider:

-

Where will the panel be used? Indoor, outdoor, or harsh environments4?

-

What is the panel’s primary function5? Structural support, control interface, or display?

-

What environmental factors6 must it withstand? Heat, moisture, corrosion, impact, or UV exposure?

-

Is aesthetics important? For consumer-facing or industrial use?

-

- -

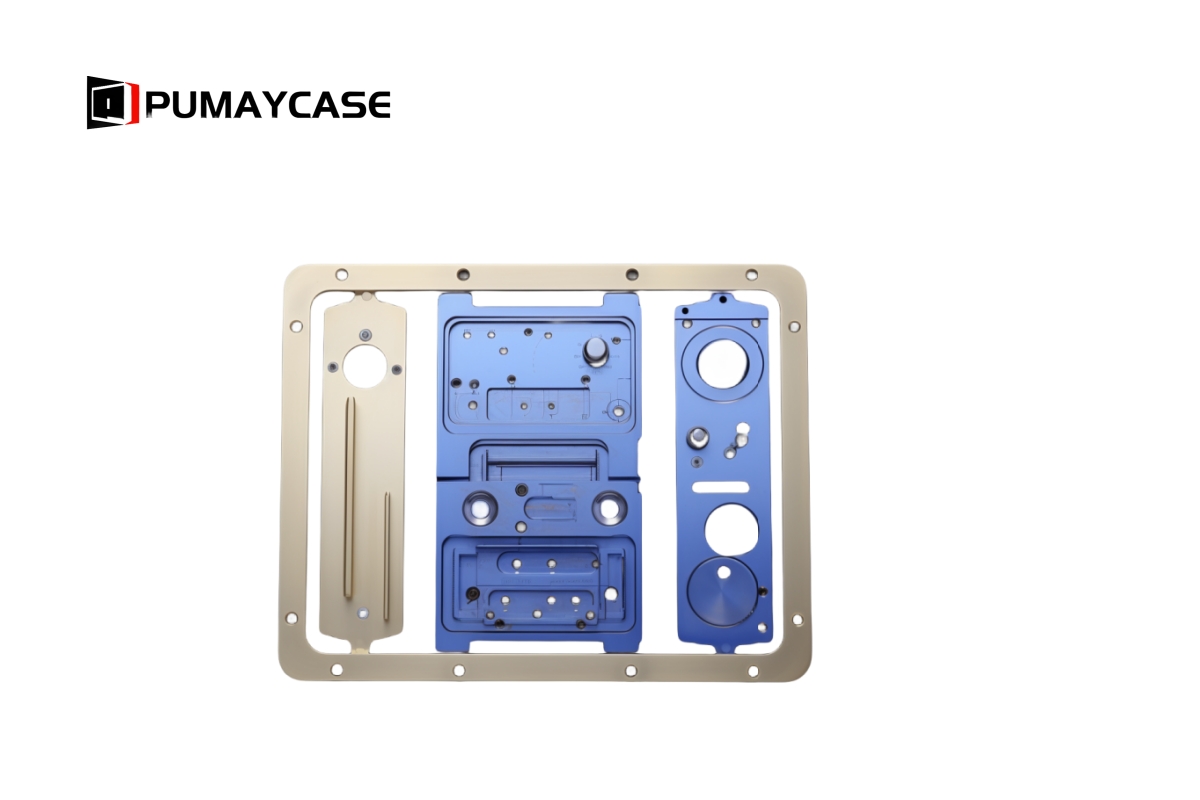

2. Choose the Appropriate Material

The material affects the panel’s durability, weight, thermal performance, and cost.

Common Panel Materials and Their Characteristics:

| Material | Features | Best for |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, good thermal dissipation | Industrial control panels, electronics housings |

| Stainless Steel | High strength, corrosion-resistant, impact-resistant | Outdoor panels, food processing, marine environments |

| Mild Steel | Strong, cost-effective, easily fabricated | Electrical cabinets, heavy-duty enclosures |

| Polycarbonate (PC) | Lightweight, impact-resistant, excellent electrical insulation | Display windows, portable devices, lab equipment |

| Acrylic (PMMA) | High transparency, UV-resistant | Display covers, control panels for aesthetics |

3. Determine Environmental Protection Needs

The panel must protect internal components from dust, moisture, chemicals, and physical damage.

Key Protection Standards:

-

IP Rating (Ingress Protection)7:

- IP54: Protection against limited dust and splashes of water.

- IP65: Dust-tight and water-resistant against low-pressure jets.

- IP67: Dust-tight and water immersion-resistant up to 1 meter.

-

IK Rating (Impact Resistance)8: Ranges from IK01 to IK10, indicating resistance to physical impacts. IK10 is the highest, suitable for vandal-resistant panels.

-

- Stainless steel or anodized aluminum for outdoor or chemical environments.

- Powder-coated steel for moderate protection.

-

- -

4. Functional Design Considerations

1. Mounting and Installation

1. Mounting and Installation

- Fixed Panels: Welded or screwed into place—used for structural or protective purposes.

- Hinged Panels10: Offer easy access for maintenance or control functions.

2. Display and Interface

- Transparent Windows: Use polycarbonate or acrylic for visible displays.

- Touchscreen Integration11: Consider tempered glass for touchscreen durability.

- Control Interfaces: Ensure proper cutouts for buttons, switches, and indicators.

Example: For a medical device, a polycarbonate panel with a touchscreen cutout12 ensures both visibility and impact protection.

3. Thermal Management

If the panel is part of an enclosure housing heat-sensitive components, include ventilation slots, heatsinks, or fan mounts.

5. Aesthetic and Branding Options

For consumer-facing products or control panels, aesthetics can enhance the user experience.

Customization Options:

- Anodizing and Powder Coating: For color consistency and corrosion protection13.

- Laser Engraving and Screen Printing: Add logos, labels, and legends for functional and brand identification.

- Brushed or Polished Finishes: For a sleek, modern appearance.

Example: High-end audio equipment often features brushed aluminum faceplates14 with engraved controls for a premium look.

6. Budget and Production Volume

The choice of panel material and features also depends on your budget and production scale.

Guidelines:

-

Low-volume production: CNC machining or 3D printing for custom designs.

-

High-volume production: Stamping, die-casting, or injection molding for cost efficiency.

-

Mid-range: Sheet metal fabrication with surface treatments offers a balance of customization and cost.

-

- -

Summary Table: Panel Selection Criteria

| Criteria | Options/Recommendations |

|---|---|

| Material | Aluminum, stainless steel, polycarbonate, acrylic |

| Environmental Protection | IP65/IP67 for outdoor, IK10 for impact resistance |

| Mounting | Fixed, hinged, or removable panels |

| Thermal Management | Ventilation slots, heatsinks, or fan integration |

| Customization | Surface treatments, engraving, and labeling |

Choosing the right panel for your project is crucial for achieving the optimal balance of functionality, protection, and aesthetics. Start by understanding your project’s specific requirements, then select the material, protection level, and design features accordingly. Whether for industrial control systems, consumer electronics, or laboratory equipment, a well-chosen panel will enhance both the performance and longevity of your product.

-

Understanding the key factors in selecting the right panel can greatly enhance your project's success and efficiency. ↩

-

Exploring these factors will provide insights into making informed decisions for your panel selection process. ↩

-

Learning about these aspects will help you prioritize essential features for your project, ensuring optimal performance. ↩

-

Understanding the challenges of harsh environments can help you choose the right materials for your project. ↩

-

Exploring the primary functions of panels can guide you in selecting the right type for your needs. ↩

-

Learning about environmental factors can ensure the longevity and effectiveness of your panels in various conditions. ↩

-

Understanding IP ratings is crucial for selecting equipment that can withstand environmental factors. Explore this link for detailed insights. ↩

-

IK ratings are essential for ensuring the durability of products against impacts. Discover more about these ratings and their applications. ↩

-

Choosing the right materials for corrosion resistance is vital for longevity. Learn about the best options available for various conditions. ↩

-

Discover the benefits of hinged panels for easy access and maintenance, crucial for efficient operations in various settings. ↩

-

Learn how touchscreen integration can enhance user interaction and functionality in modern devices, making them more intuitive and efficient. ↩

-

Explore this link to understand how polycarbonate panels enhance visibility and durability in various applications, especially in medical devices. ↩

-

Learn how anodizing enhances the longevity of materials by providing effective corrosion protection. ↩

-

Explore the advantages of brushed aluminum faceplates for aesthetics and durability in various applications. ↩