Laboratory instruments often house sensitive electronic components that are vulnerable to electrostatic discharge (ESD)1 and electromagnetic interference (EMI)2. Designing aluminum enclosures with proper electrostatic protection (EPA)3 and electromagnetic compatibility (EMC) is crucial for ensuring stable performance, accuracy, and device longevity.

An effective solution includes conductive materials, grounding, shielding, and filtering techniques.

1. Electrostatic Protection (ESD) Solutions

Why ESD Protection Is Critical

Electrostatic discharges4 can damage sensitive electronics, leading to performance degradation, data loss, or permanent failure. In laboratory environments, frequent contact with personnel and nearby equipment increases the risk of ESD events.

Key ESD Protection Design Techniques

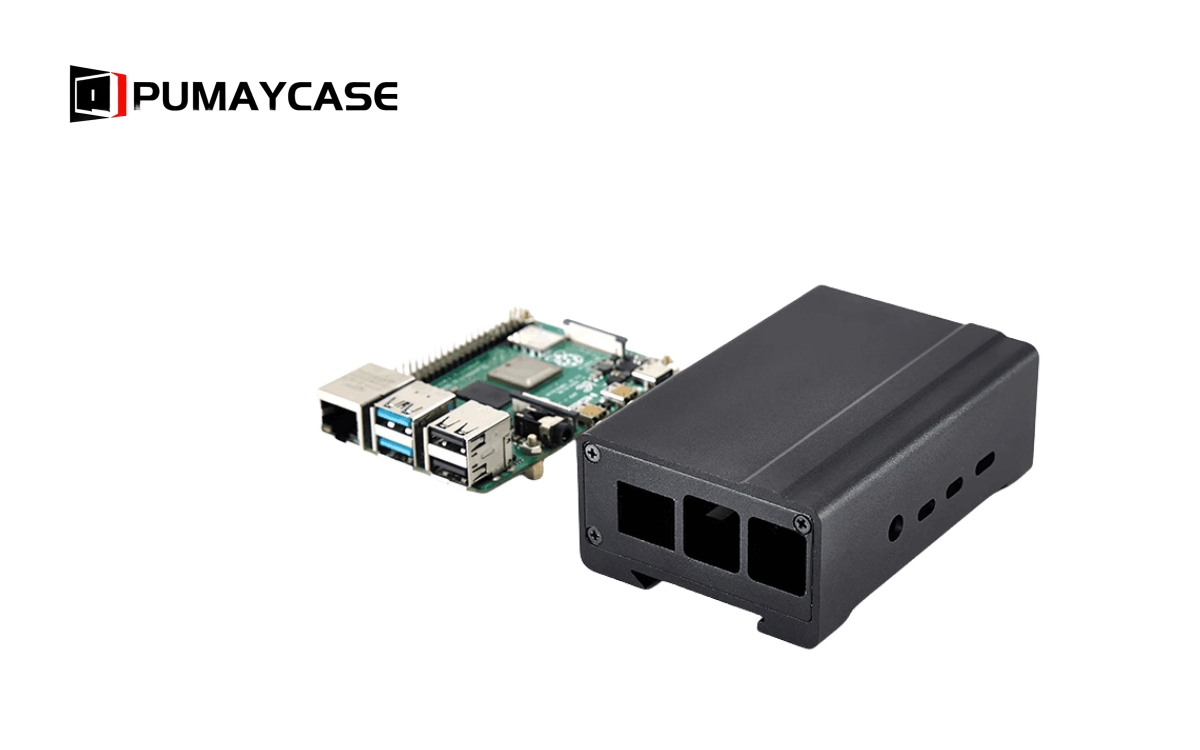

Conductive Aluminum Enclosure

Aluminum is naturally conductive and provides basic ESD protection5 by dissipating static charges.

- Anodized Aluminum: Maintains conductivity while offering corrosion resistance.

- Surface Conductive Coatings: Use nickel or carbon-based conductive coatings for enhanced ESD protection.

Grounding the Enclosure

Ensure the enclosure is properly grounded to safely discharge static electricity.

- Internal Grounding Points: Connect the enclosure to a dedicated ground line.

- ESD Grounding Straps: For high-sensitivity instruments, use grounding straps to create an electrostatic-safe path.

ESD Suppression Components

Install ESD suppressors6 and TVS (Transient Voltage Suppression) diodes on I/O ports to protect sensitive electronics from sudden discharges.

2. EMC (Electromagnetic Compatibility) Solutions

Why EMC Matters

Electromagnetic interference (EMI) can disrupt the operation of laboratory instruments, especially those handling precision measurements7 or high-frequency signals. Proper shielding and filtering are essential for meeting EMC standards.

Key EMC Protection Design Techniques

Faraday Cage Principle

An aluminum enclosure acts as a Faraday cage8, shielding the internal components from external EMI. For optimal shielding:

- Ensure seamless contact at all joints.

- Avoid gaps or poorly connected seams that could compromise shielding.

- Use EMI gaskets on doors and removable panels to maintain continuous shielding.

Filtering and Decoupling

Install EMI filters9 on power and signal lines to reduce conducted interference.

- Power Line Filters: Block high-frequency noise entering through AC power lines.

- Ferrite Beads and Decoupling Capacitors: Suppress high-frequency noise on data lines and PCBs.

Cable Shielding and Grounding

External cables can act as antennas for EMI. Proper shielding and grounding reduce noise coupling.

-

Use shielded cables with grounded connectors.

-

Minimize the length of high-frequency signal cables to reduce radiation.

-

- -

3. Combined ESD and EMC Solutions

Material Selection

- Conductive Coatings: Use nickel-plated or copper-based conductive coatings for enhanced EMI and ESD protection.

- Aluminum Alloys (6063 or 5052): Provide high mechanical strength, good conductivity, and natural shielding.

Design Considerations

-

Multi-layer Shielding: Combine internal conductive coatings with external grounding for maximum EMC/ESD protection.

-

PCB Layout Optimization: Minimize high-speed signal loops and use ground planes to reduce internal EMI generation.

-

- -

4. Compliance with International Standards

Relevant Standards:

- IEC 61340-5-1: ESD control requirements.

- IEC 61000-4-2: ESD immunity testing.

- IEC 61000-4-4: EMC fast transient/burst immunity.

- CISPR 32 / EN 55032: EMC requirements for multimedia equipment.

Meeting these standards ensures that laboratory instruments can safely operate in environments with multiple electronic devices without interference or damage.

Real-World Application Example

Precision Laboratory Analyzer – ESD and EMC Protection Design

Challenge:\

A laboratory analyzer for high-precision chemical measurements experienced frequent failures due to ESD events and external electromagnetic noise from nearby equipment.

Solution:

- Aluminum Enclosure with Conductive Coating: Enhanced shielding and electrostatic discharge capability.

- EMI Gaskets and Shielded Connectors: Reduced electromagnetic interference at all access points.

- Power Line Filters: Protected internal circuits from conducted noise.

- Grounding and ESD Suppressors: Safely discharged static electricity without affecting internal electronics.

Result:

-

50% reduction in ESD-related failures.

-

Significant improvement in measurement accuracy and stability.

-

Compliance with IEC 61000-4-2 and CISPR 32 standards.

-

- -

The End

In laboratory instruments, ESD and EMC protection is essential for ensuring reliability and performance. Aluminum enclosures, combined with proper grounding, shielding, and filtering techniques, provide an effective solution. By following best practices and adhering to relevant standards, manufacturers can create safer, more durable devices that thrive in high-risk environments.

-

Understanding ESD prevention is vital for protecting sensitive lab equipment. Explore this resource for effective strategies. ↩

-

Minimizing EMI is essential for device reliability. This link offers insights into effective EMI reduction techniques. ↩

-

Learn about the significance of EPA in safeguarding electronic components from damage. This resource provides valuable information. ↩

-

Understanding the impact of electrostatic discharges can help you implement better protection strategies for your devices. ↩

-

Exploring basic ESD protection methods can enhance your knowledge and application of effective protective measures. ↩

-

Learning about ESD suppressors will provide insights into advanced protection techniques for sensitive electronic components. ↩

-

Understanding precision measurements is crucial for ensuring accurate results in EMC testing and compliance. ↩

-

Exploring the Faraday cage principle can enhance your knowledge of effective EMI shielding techniques. ↩

-

Learning about EMI filters can help you choose the right solutions for minimizing interference in sensitive equipment. ↩