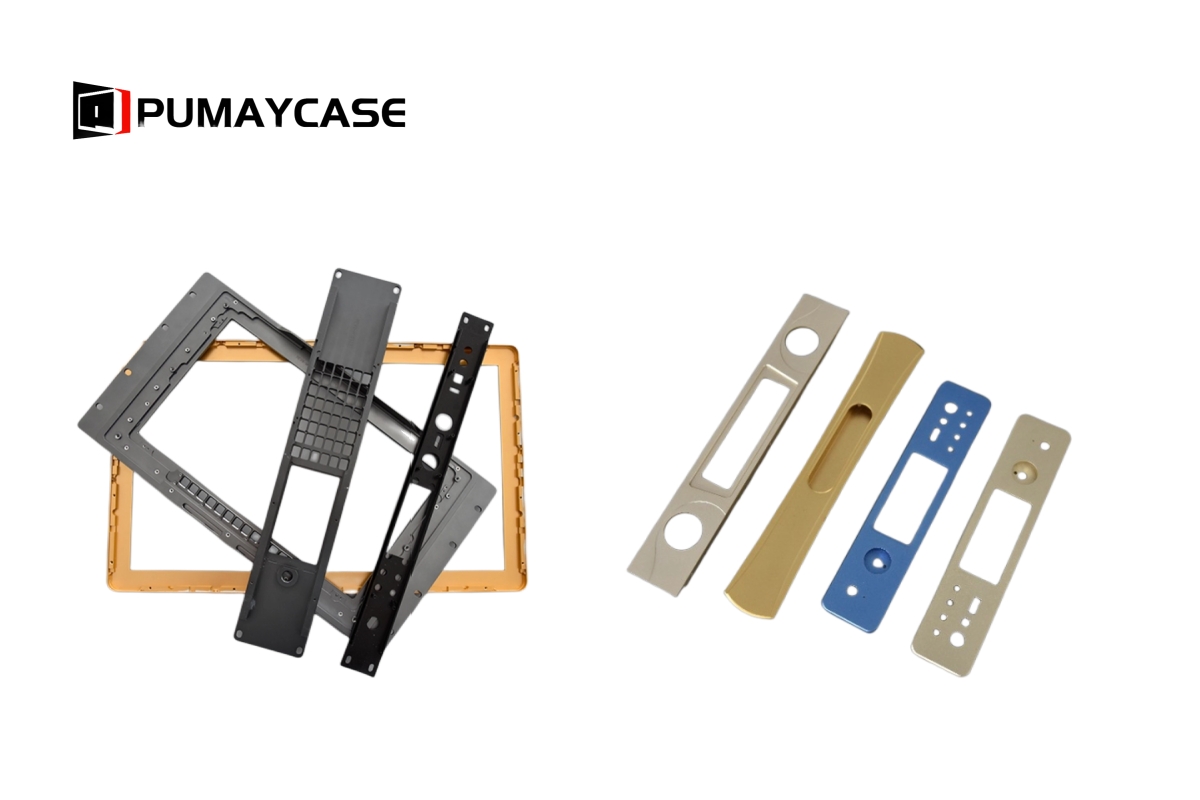

Custom logos on aluminum panels not only enhance a product’s appearance but also strengthen brand identity. Whether for industrial control panels, electronic devices, or consumer products, a well-executed logo adds a professional and recognizable touch.

At Pumaycase, we use advanced techniques such as laser engraving, silk-screen printing, and UV printing to create durable, high-quality custom logos on aluminum surfaces.

Here’s a real-world example of how we helped a client with logo customization.

Case 1: Laser-Engraved Logo for an Industrial Control Panel

Client: Industrial Automation Company\

Project: Aluminum front panel for an industrial control system\

Logo Style: Minimalist, engraved logo with a metallic finish

Challenge:

The client needed a logo that could withstand harsh environments, including high temperatures and chemical exposure, without fading or peeling.

Solution:

We recommended laser engraving for the logo, as it offers:

- High durability: Resistant to wear, heat, and chemical exposure

- Permanent marking: No risk of peeling or fading over time

- Sleek metallic finish: Matches the panel’s anodized surface

Process:

- We received the client’s vector logo file in AI format.

- The logo was precisely engraved using a high-power laser on the anodized aluminum panel.

- The final result was a clean, professional logo that blended seamlessly with the panel’s surface.

Result:

-

The logo remained intact and legible after extensive durability testing, including chemical resistance and thermal cycling.

-

The client was impressed with the elegant, industrial-grade appearance of the logo.

-

- -

Case 2: Full-Color UV Printed Logo for a Consumer Electronics Panel

Client: Startup in Consumer Electronics\

Project: Custom aluminum panel for a smart home device\

Logo Style: Full-color logo with gradient effects

Challenge:

The client wanted a colorful logo with precise color reproduction and a glossy finish. The logo also needed to withstand frequent handling and minor abrasions.

Solution:

We used UV printing, which provides:

- Vivid, full-color reproduction: Supports gradients and complex designs

- Abrasion resistance: Protects the logo from scratches

- Glossy or matte finish options: For a premium look

Process:

- We color-matched the logo using a Pantone reference provided by the client.

- The UV printer applied the logo directly onto the aluminum panel with a protective coating.

Result:

-

The final product featured a vibrant, full-color logo with excellent durability.

-

The client received positive feedback from customers on the device’s sleek and polished design.

-

- -

Logo Customization Techniques at Pumaycase

| Technique | Appearance | Durability | Best Use Case |

|---|---|---|---|

| Laser Engraving | Metallic, precise | Very High | Industrial equipment, outdoor panels |

| Silk-Screen Printing | Solid colors, bold design | Moderate | Control panels, branding elements |

| UV Printing | Full-color, gradient support | High | Consumer electronics, decorative panels |

Case 3: Silk-Screen Printed Logo for a Medical Device Panel

Client: Medical Equipment Manufacturer\

Project: Front panel for a diagnostic device\

Logo Style: Single-color, high-contrast logo

Challenge:

The client needed a clean, high-contrast logo that complied with medical standards for durability and chemical resistance.

Solution:

We used silk-screen printing with high-durability inks that resist cleaning agents and wear.

Process:

- The logo was printed in white on a black anodized aluminum surface for maximum contrast.

- After printing, the panel underwent a curing process to ensure ink adhesion and durability.

Result:

-

The logo remained clear and legible even after repeated cleaning with disinfectants.

-

The client was pleased with the professional, medical-grade appearance.

-

- -

Tips for Successful Logo Customization on Aluminum Panels

- Use High-Quality Vector Files: Ensure your logo is in vector format (AI, EPS) for maximum precision.

- Choose the Right Technique: Consider durability, appearance, and application environment when selecting the logo process.

- Plan for Surface Treatments: Anodizing or powder coating may affect logo adhesion—coordinate the design with surface finishing plans.

Conclusion

Custom logos on aluminum panels add value, improve aesthetics, and strengthen brand identity. Whether through laser engraving for industrial use or UV printing for vibrant consumer products, Pumaycase offers tailored solutions to meet every client’s needs. With the right technique and attention to detail, your logo can become a defining feature of your product.