Adding a custom logo to an aluminum enclosure is an excellent way to enhance brand visibility and create a professional look for your products. Understanding the customization process and reviewing successful cases can help you make the right choices.

Pumaycase provides a streamlined logo customization process with multiple techniques, ensuring your logo appears precisely as you envision it.

Let’s explore the step-by-step process and some real-world examples.

What Is the Process for Customizing a Logo on an Enclosure?

The logo customization process at Pumaycase is straightforward and customer-focused.

From design submission to production, each step ensures accuracy and quality.

Step-by-Step Process:

Design Submission

- Provide your logo file in high-resolution format (AI, EPS, or PDF preferred).

- Specify the desired size, position, and color for the logo.

Material and Technique Selection

- Choose the appropriate surface treatment (anodized, powder-coated, etc.).

- Select the logo application technique, such as laser engraving, screen printing, or UV printing.

Mockup and Approval

- We create a digital mockup for your review and approval.

- Adjustments can be made to ensure the design meets your expectations.

Production

- After approval, we proceed with the production using advanced machinery for precise application.

Quality Inspection and Delivery

- Each product undergoes a thorough quality check before shipping.

What Logo Application Techniques Are Available?

Different techniques offer unique finishes and durability for your logo.

| Technique | Appearance | Durability | Recommended For |

|---|---|---|---|

| Laser Engraving | Permanent, metallic look | Very High | Industrial applications |

| Screen Printing | Bright, vibrant colors | Moderate | Consumer products |

| UV Printing | Full-color, high precision | High | Branding and logos with gradients |

Laser engraving is perfect for a clean and professional look, while UV printing offers maximum design flexibility.

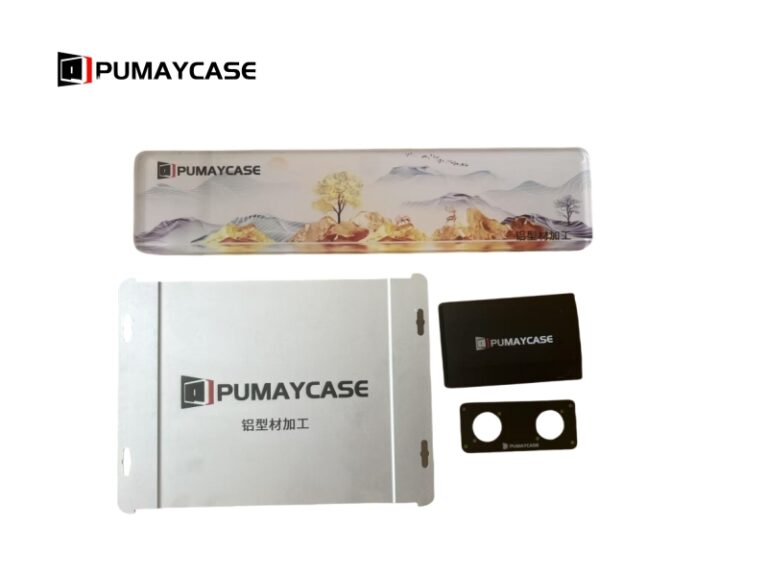

Case Studies: Successful Logo Customization

Case 1: Industrial Control Panel for a Robotics Company

Challenge: The client needed a durable, long-lasting logo for an industrial control panel used in high-temperature environments.

Solution: Pumaycase recommended laser engraving on an anodized aluminum surface for durability and a sleek metallic finish. The result was a highly visible, professional logo that could withstand harsh conditions.

Case 2: Consumer Electronics Enclosure

Challenge: A startup in the consumer electronics industry wanted a multi-color logo on their aluminum enclosure for a premium look.

Solution: We used UV printing to reproduce the logo with full-color gradients and high precision. The final product enhanced the brand’s visual appeal and stood out in the market.

Case 3: Medical Device Housing

Challenge: The client required a sterile, easy-to-clean surface with a subtle logo for medical environments.

Solution: We suggested laser engraving, which provided a clean, non-porous surface without compromising the aesthetics or hygiene requirements.

Tips for a Successful Logo Customization

- Use High-Resolution Files: Low-quality images can result in blurry or distorted logos.

- Choose the Right Technique: Consider durability, appearance, and budget when selecting the logo application method.

- Communicate Clearly: Provide detailed instructions on size, placement, and color to avoid misunderstandings.

Conclusion

Custom logo services at Pumaycase offer multiple options for creating a professional, branded look. With a clear process and diverse application techniques, you can bring your design to life while enhancing your product’s value.