Electromagnetic interference (EMI) can cause serious device malfunctions. A reliable aluminum enclosure1 offers effective shielding.

Aluminum enclosures provide excellent electromagnetic shielding2, protecting sensitive components from external interference.

Understanding the factors that influence shielding performance3 helps in selecting the right enclosure for your needs.

Why Is Aluminum a Good Choice for Electromagnetic Shielding?

Aluminum is widely used for its combination of light weight and conductivity.

Its high conductivity4 effectively blocks electromagnetic waves, ensuring component stability and protection.

Compared to other metals, aluminum is more cost-effective5 while maintaining reliable shielding capabilities6.

What Factors Affect the Shielding Performance of Aluminum Enclosures?

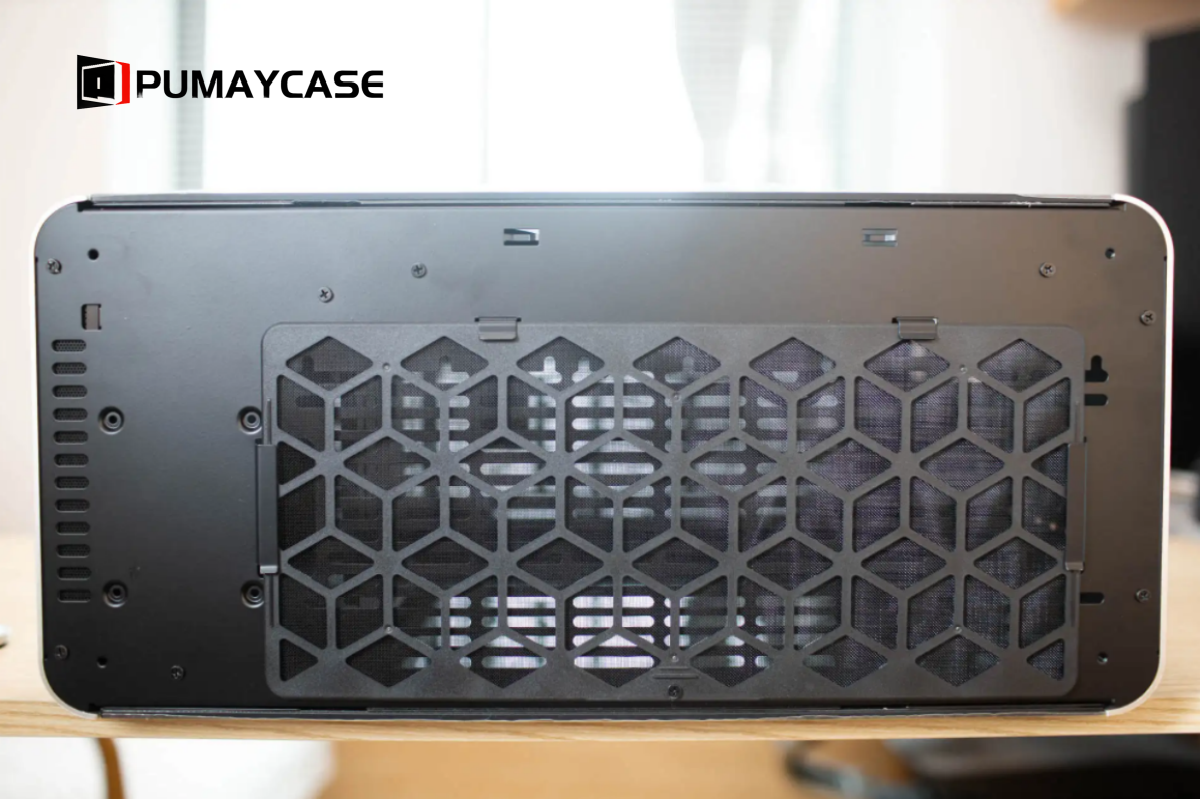

Not all aluminum enclosures offer the same level of shielding. Factors such as material thickness, enclosure design, and assembly quality matter.

Key factors include material conductivity, seam design, and surface treatments.

- Thickness: Thicker aluminum generally improves shielding effectiveness.

- Seams and Joints: Gaps reduce shielding performance; seamless designs are preferred.

- Surface Treatments: Anodized coatings may reduce conductivity, while conductive gaskets can enhance performance.

Aluminum vs. Other Metals for EMI Shielding

Here’s a comparison of common metals used for shielding:

| Metal | Conductivity | Weight | Cost Efficiency | Shielding Performance |

|---|---|---|---|---|

| Aluminum | High | Light | High | Excellent |

| Copper | Very High | Heavy | Low | Superior |

| Steel | Moderate | Heavy | Moderate | Good |

How to Test the Shielding Effectiveness of an Aluminum Enclosure?

There are several methods to test the EMI shielding effectiveness of an aluminum enclosure:

- Shielding Effectiveness Testing (SET)7 – Measures attenuation of electromagnetic waves.

- Field Testing8 – Simulates real-world conditions to assess performance.

- Frequency-Specific Testing9 – Ensures reliability across different frequency ranges.

For accurate results, it is recommended to use certified labs and professional equipment.

What Applications Require High EMI Shielding?

Industries that prioritize EMI protection include:

- Telecommunications: Protecting sensitive electronic circuits.

- Medical Devices: Ensuring safe and accurate device operation.

- Aerospace and Defense: Shielding critical communication systems.

Conclusion

Aluminum enclosures offer reliable and cost-effective electromagnetic shielding, ensuring the safety and performance of sensitive electronic devices.

-

Discover why aluminum enclosures are preferred for EMI protection and how they can enhance device reliability. ↩

-

Explore this link to understand the principles of electromagnetic shielding and its importance in protecting devices from interference. ↩

-

Learn about the key factors that affect shielding performance to make informed decisions for your enclosure needs. ↩

-

Understanding the benefits of high conductivity can enhance your knowledge of material selection for various applications. ↩

-

Exploring the cost-effectiveness of aluminum can help you make informed decisions in material procurement and budgeting. ↩

-

Learning about reliable shielding capabilities can improve your understanding of material performance in electronic applications. ↩

-

Understanding SET is crucial for evaluating how well materials protect against electromagnetic interference, enhancing design choices. ↩

-

Field Testing provides insights into real-world performance, ensuring that products meet user expectations and regulatory standards. ↩

-

Frequency-Specific Testing is vital for confirming that devices function correctly across various frequencies, which is essential for effective communication. ↩