In fast prototyping, selecting the right supplier is crucial for ensuring quality, speed, and cost-efficiency. Whether you need custom enclosures, precision parts, or functional prototypes, working with a reliable supplier helps reduce development time and improve product success.

Here are the 5 essential standards for evaluating and selecting a supplier for rapid prototyping.

1. Speed and Delivery Capability

Why It Matters:\

In fast prototyping, delivery time is critical. A capable supplier must have the infrastructure and workflow to meet tight deadlines without sacrificing quality.

What to Check:

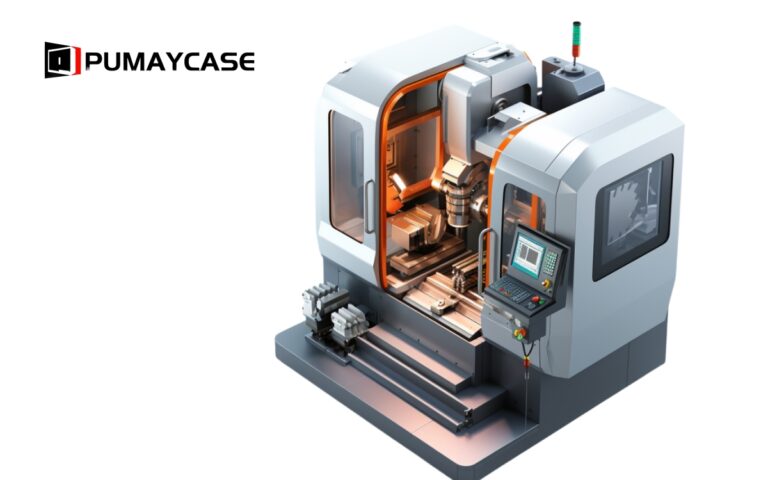

- In-house production capacity: CNC machining, 3D printing, sheet metal processing, or injection molding.

- Lead time: Ask for typical turnaround times for different processes (e.g., 48–72 hours for CNC parts).

- Logistics network: Ensure they offer express shipping options for quick delivery.

Pro Tip: Choose a supplier with an automated order tracking system for real-time updates.

2. Technical Expertise and Range of Services

Why It Matters:\

A supplier with diverse manufacturing capabilities and deep technical knowledge can handle complex designs and offer valuable feedback for improvement.

What to Check:

- Core processes: CNC machining, 3D printing, sheet metal fabrication, anodizing, powder coating, and surface treatments.

- Design for Manufacturing (DFM) support: Can they suggest improvements for manufacturability?

- Material availability: Ensure they work with the required materials (aluminum, stainless steel, plastics, etc.).

Pro Tip: Ask for samples of previous projects in similar industries.

3. Quality Assurance (QA) Standards

Why It Matters:\

Fast delivery is worthless without high-quality output. Ensure the supplier has strict quality control processes in place to avoid defects.

What to Check:

- ISO Certifications: Look for ISO 9001 or other relevant certifications.

- Inspection capabilities: Dimensional inspection, CMM (Coordinate Measuring Machine), surface roughness testing, etc.

- Material traceability: Especially critical for aerospace, automotive, and medical prototypes.

- Quality documentation: Request reports such as First Article Inspection (FAI) or test certificates.

Pro Tip: Choose suppliers who offer visual inspection reports or automated quality checks for consistent accuracy.

4. Flexibility and Customization Options

Why It Matters:\

Prototyping often requires low-volume production with custom specifications. A good supplier should be flexible and willing to adapt to your unique needs.

What to Check:

- Minimum Order Quantity (MOQ): Ensure they can handle small batch or one-off production.

- Customization: Ask if they provide special finishes, engraving, or packaging services.

- Modifications: Check if they offer quick design iterations and rework services without long delays.

Pro Tip: Work with a supplier that supports modular or on-demand production.

5. Communication and Customer Support

Why It Matters:\

Effective communication ensures smooth collaboration, especially when handling tight timelines and design adjustments.

What to Check:

- Responsiveness: How fast do they respond to inquiries?

- Dedicated support team: Ensure you have a single point of contact for updates and problem-solving.

- Language proficiency: For international suppliers, good communication in English is essential.

- Technical support: Can they provide detailed answers about materials, processes, and tolerances?

Pro Tip: Choose a supplier with a 24/7 support team for urgent requests.

Summary Table: Supplier Evaluation Checklist

| Criteria | What to Look For |

|---|---|

| Speed & Delivery | Fast turnaround, in-house capacity, reliable logistics |

| Technical Expertise | Diverse capabilities, DFM support, material availability |

| Quality Assurance | ISO certifications, CMM inspection, quality reports |

| Flexibility | Low MOQ, customization options, fast design iterations |

| Communication | Fast response time, dedicated support, technical knowledge |

The End

When selecting a supplier for fast prototyping, prioritize speed, technical expertise, quality control, and responsive communication. Working with the right partner ensures that your prototypes meet expectations in both performance and delivery, helping you accelerate time-to-market and stay competitive.